二手 TEL / TOKYO ELECTRON Clean Track ACT 12 #9190227 待售

网址复制成功!

单击可缩放

ID: 9190227

晶圆大小: 8"

优质的: 2001

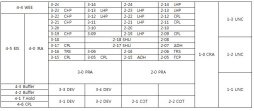

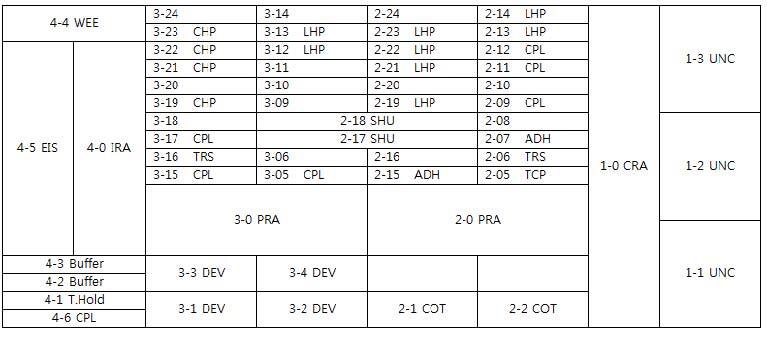

(2) Coaters / (4) Developers system, 8"

In-line

Right to left

Loading configuration: 3 Foup type

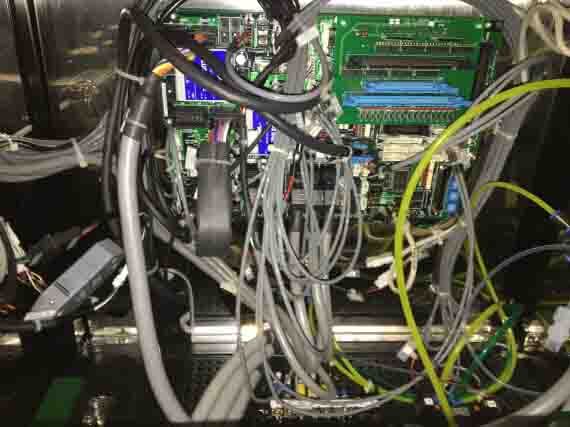

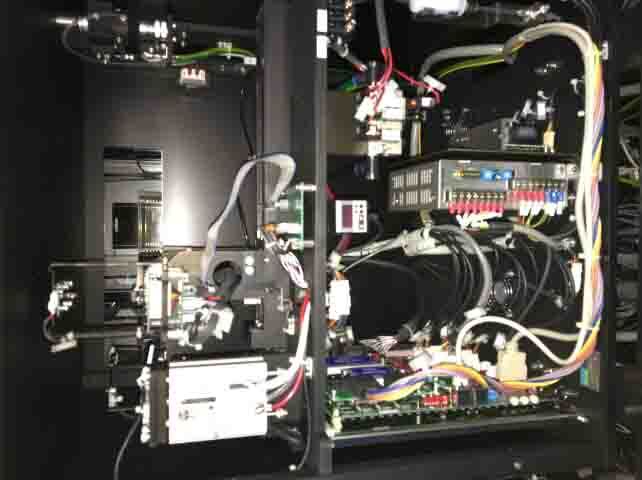

Main controller: 2nd Controller

Main frame with system controller

CSB

PRB1

PRB2

IFB

Power box

T&H Controller

Chemical box

Thermo controller

(2) Mass flow controllers

Carrier station: 8" Foup type

(3) Cassettes / (25) Slots

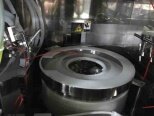

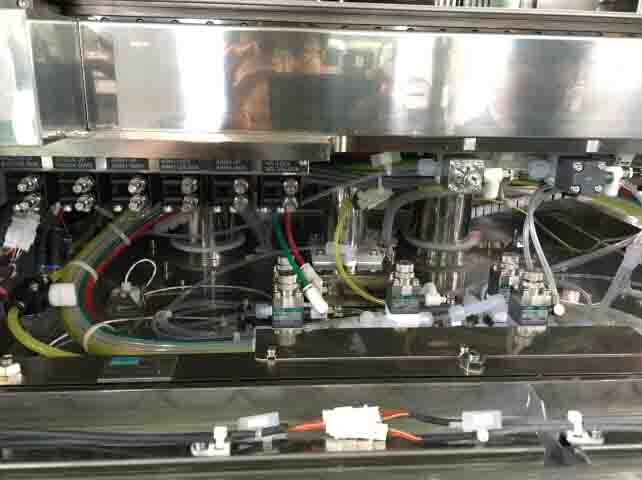

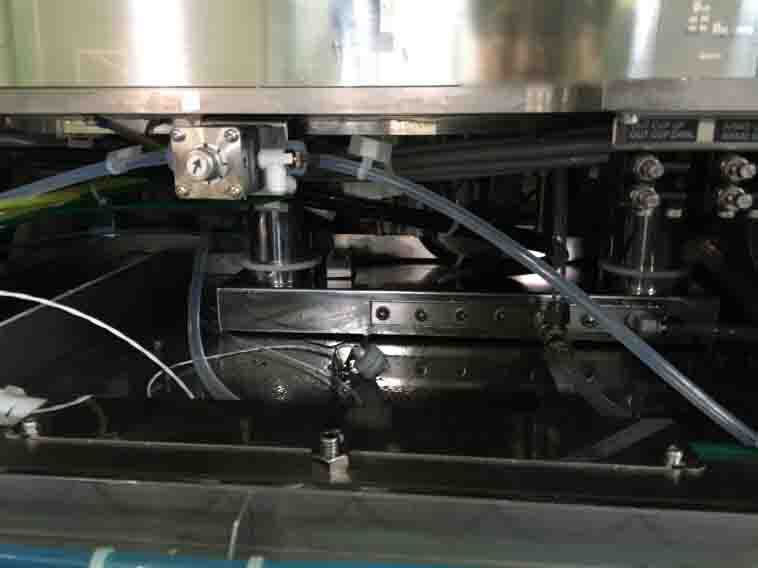

Coater unit (2-1, 2-2 Module):

(4) Dispense nozzles

With temperature controlled lines for etch unit

RRC Pump

PR Suck-back valve: (8) Air operation suck-back valves

Rinse system:

(3) Liters

(2) Tanks

Buffer tank system

Programmable side rinse

(4) PR Nozzles

(8) Bottles

Thinner supply:

CCSS Supply

Local canister tank function

Photo resist temperature control system

Drain: Direct drain

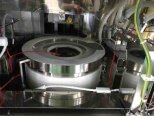

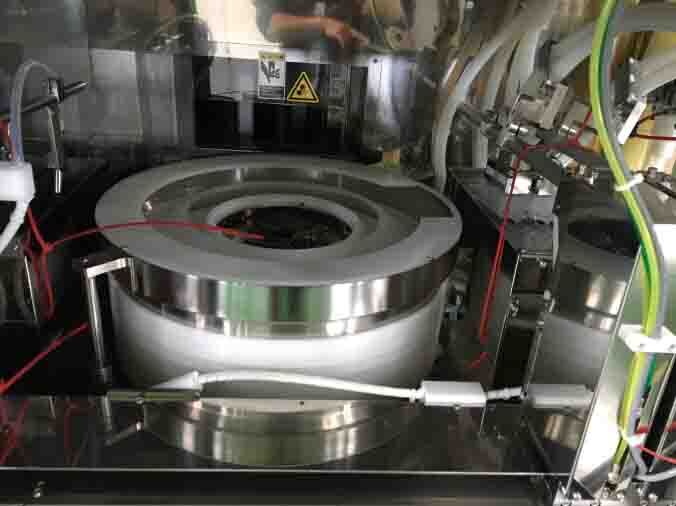

Developer unit (3-1, 3-2, 3-3, 3-4):

(2) H Nozzles for each unit

Stream nozzle for DI rinse

(2) Points for back side rinse on each unit

Developer temperature control system

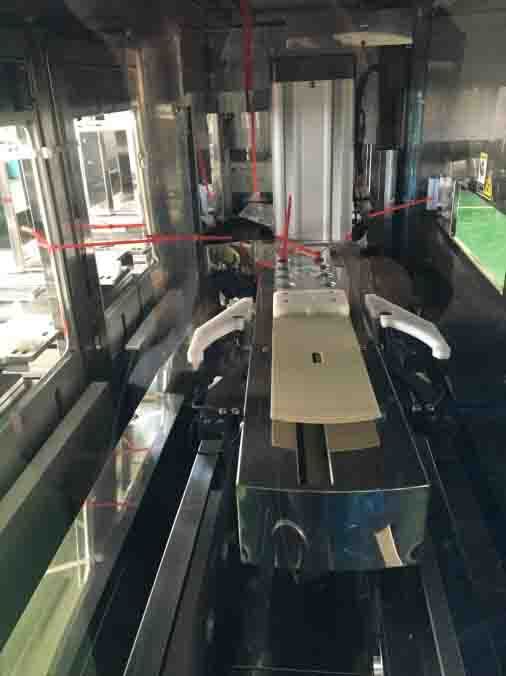

I/F Wafer stage type: NIKON (S204)

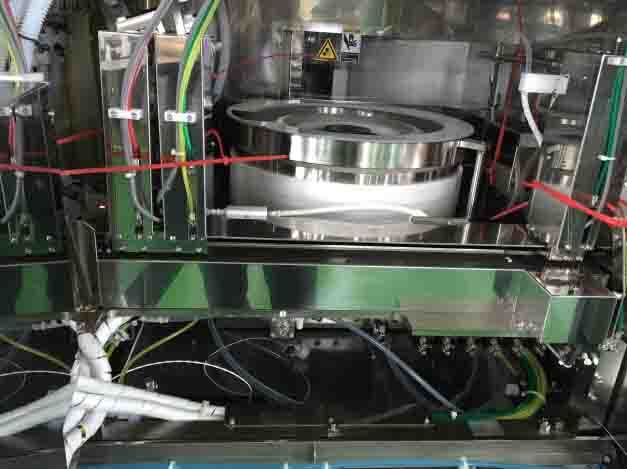

Adhesion unit:

100% Sealing closed chamber (Built-in hot plate)

HMDS Tank with float sensor in system

HMDS Supply: Local bottle

(8) Low temperature hot plates (LHP)

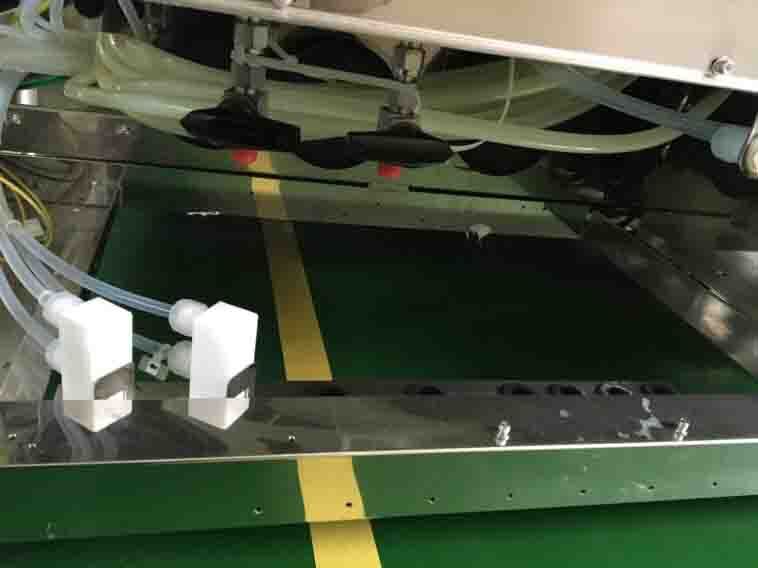

WEE Unit (Wafer edge exposure)

Type: DUV (UV254)

(7) Chill plates (CPL)

(4) Chilling hot plates (CHP)

TCP Unit

(2) TRS Units

SHU: (2) Shuttles

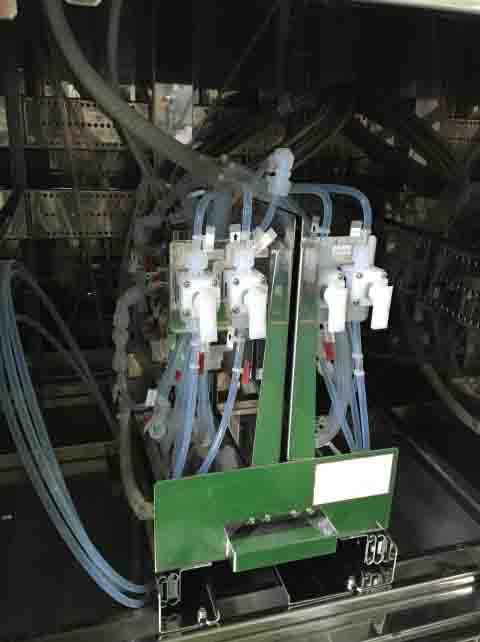

Chemical cabinet 1:

Solvent

Developer

HMDS Chemical cabinet

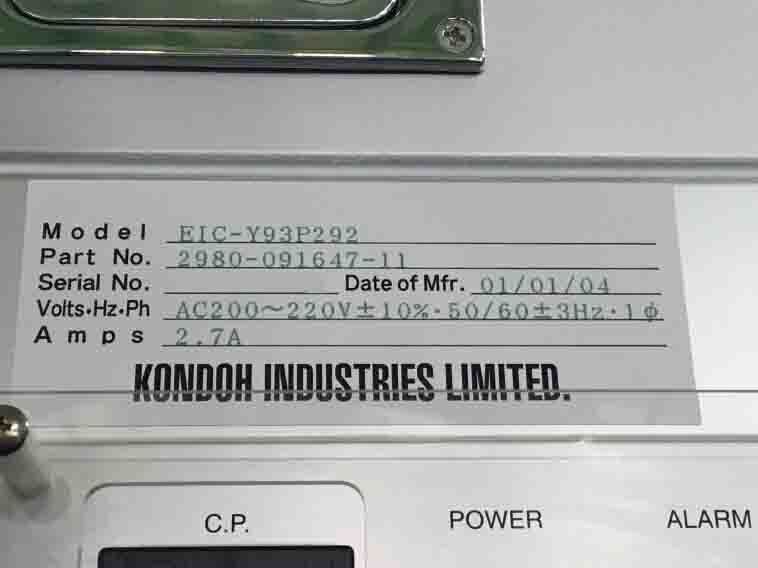

Temperature & humidity controller: Shinwa series (ESA-8)

Temperature control unit(TCU): TEL

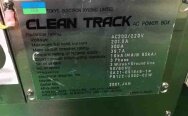

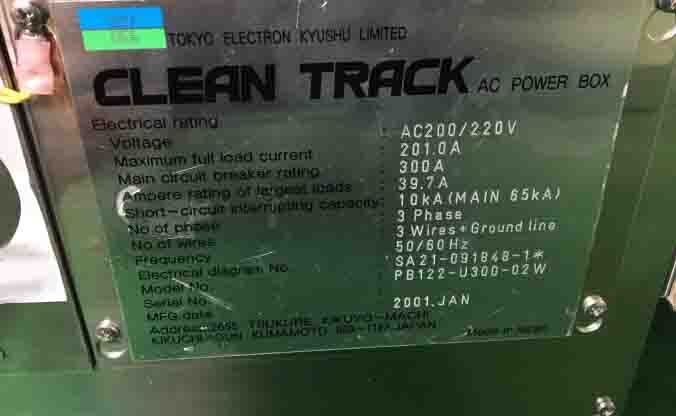

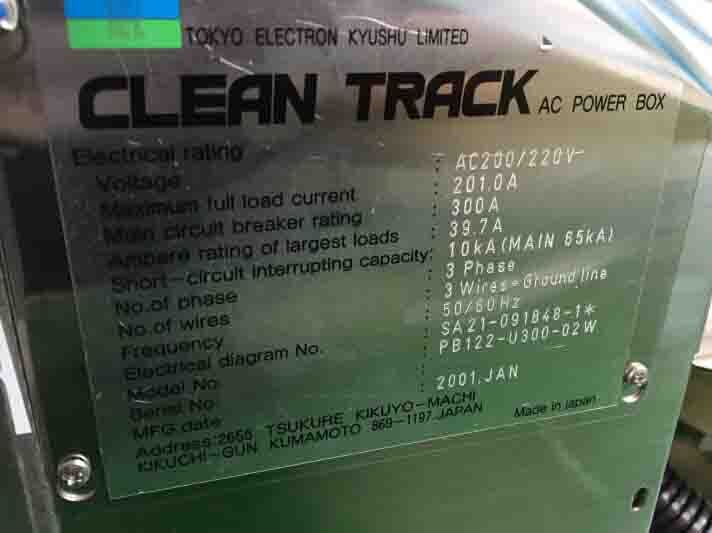

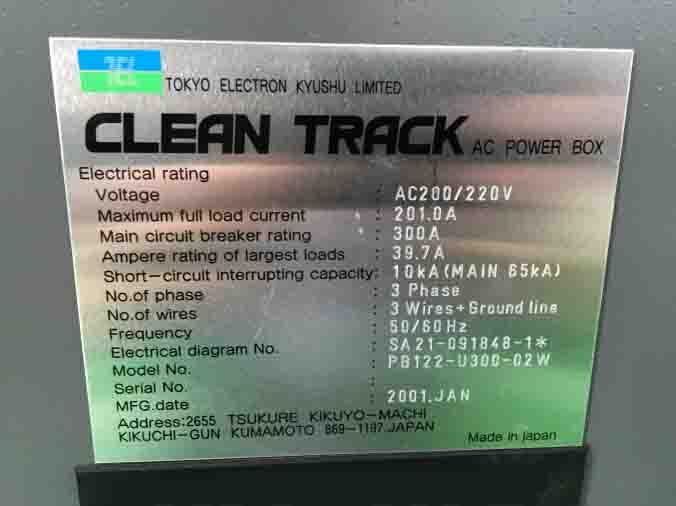

AC Power box:

AC200 / 220V

Full-load current: 300A

Power: AC 208V, 3 Phase, 300A (Maximum)

2001 vintage.

TEL/TOKYO ELECTRON CLEan Track ACT 12是市面上最新、最先进的光刻胶设备。它是为在洁净室环境中超低颗粒性能而设计的。该系统采用独特的技术组合,包括确保颗粒清洁的专有清洁轨道自动清洁(CTAC)工艺和先进的自上而下扫描工具,以便于维护。清洁轨道自动清洁(CTAC)过程利用两个顺序阶段来确保最高的无粒子环境。首先,使用两个独立的活化刷子模块将粒子从任何表面轮廓中移出。这些刷毛精确地根据零件或设备的形状和尺寸量身定制,确保有效清除所有污染物。其次,用高气流单元从表面提取脱落的颗粒。高气流还对表面施加防静电,进一步改善无颗粒环境。机器还利用专有的扫描技术来检测任何剩余的粒子。扫描工具利用16通道传感器阵列检测小到1微米的颗粒。传感器测量和比较包括大小、形状和密度在内的粒子特性,从而能够准确识别粒子计数。通过这一扫描过程,该工具能够检测和去除低于行业标准的颗粒水平。TEL Clean Track ACT 12资产还利用先进的温度、湿度和臭氧监测技术,以确保清洁室环境得到持续维护。温度和湿度传感器监视环境,以便根据需要调整模型。此外,臭氧传感器用于检测任何产生臭氧的粒子的存在,并相应调整设备的臭氧产量。该系统为用户提供了完整的控制,允许对清洁过程进行精确监控。此外,灰尘和防静电系统都提供先进的统计分析工具,使用户能够监测清洁阈值并确保最佳无颗粒性能。总体而言,TOKYO ELECTRON CLEan Track ACT 12是一款高度先进的光致抗蚀剂装置,使用户能够在洁净室环境中达到最高水平的洁净度。机器利用先进技术的组合,以允许恒定的无粒子性能,同时提供对清洁过程的完全控制。

还没有评论