二手 TEL / TOKYO ELECTRON Clean Track ACT 12 #9216089 待售

网址复制成功!

单击可缩放

ID: 9216089

晶圆大小: 12"

优质的: 2008

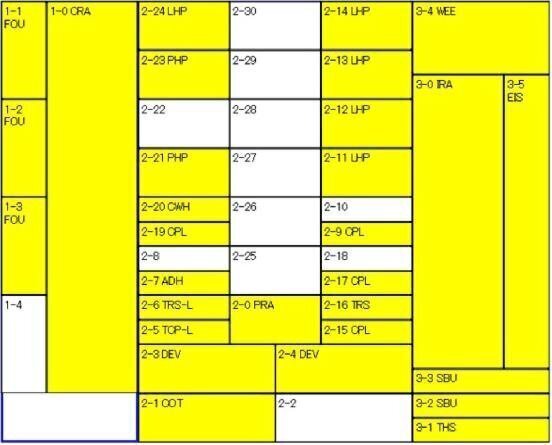

Coater / (2) Developer system, 12"

With system controller

Left to right

I/F Wafer stage type: NIKON Type (SFl3)

Carrier station:

Foup cassette

Uni-cassette

(3) Cassettes

Coater unit:

(6) Dispense nozzles with temperature controlled lines

MILLIPORE RDS Pump

Rinse nozzle: Back / EBR / Solvent bath

Rinse system: 3 Liters (2) buffer tanks

Degassing system

Programmable side rinse:

PR Nozzles (1-6): (36) Bottles

Thinner supply (Bottle / Nozzle): CCSS

AMC Suck-back valve

Direct drain

Developer unit:

H-Nozzle

Stream nozzle for DI rinse

Developer system:

(2) 3 Liters buffer tanks

Developer supply: CCSS

Degassing system

Developer temperature control system

Direct drain

Adhesion unit:

Sealing closed chamber

HMDS Tank with float sensor

HMDS Supply: Local bottle

(5) Low temperature hot plates (LHP)

(4) Chill plates (CPL)

(4) Precision chilling hot plates (CHP)

TCP Unit

(2) TRS Units

WEE Unit (Wafer edge exposure)

UV Sensor: I-line

Chemical cabinet:

Solvent

HMDS

DEV Chemical cabinet

SHINWA ESA-8 Series Temperature / Humidity controller

Temperature Control Unit (TCU)

AC Power box

2008 vintage.

TEL/TOKYO ELECTRON CLEan Track ACT 12是一种光致抗蚀剂设备,用于半导体制造。它由一个光致抗蚀剂处理系统和一个步进轨迹组合成一个集成单元,提供低颗粒环境。光敏装置是半导体器件制造的第一步,用于在基板上制作小图桉。光致抗蚀剂暴露于光,无论是从一个光掩模或电子束,取决于图案正在创建。然后开发出暴露的光致抗蚀剂,并将产生的图样转移到基材上。TEL Clean Track ACT 12旨在尽可能高效、清洁、低颗粒。这是通过其先进的步进轨迹机实现的,该机与光刻加工工具配合工作。步进轨道资产的设计目的是减少曝光过程中光掩模产生的粒子数量。它通过在处理过程中捕获粒子并将它们隔离在轨道和光掩模之间来做到这一点。然后将颗粒安全地清除和处置。TOKYO ELECTRON Clean Track ACT 12还具有先进的温度跟踪模型,可以通过将电子束温度与过程时间和剂量相关联来直接加强温度控制。这减少了加工过程中温度变化造成缺陷的几率。CleanTrackACT 12是半导体制造领域迅速发展的一个宝贵工具。它结合了先进的光致抗蚀剂加工、步进跟踪设备和温度跟踪能力,在低颗粒环境中提供了精确的结果。由于其效率和有效性,它在设备制造商中越来越受欢迎。

还没有评论