二手 TEL / TOKYO ELECTRON Clean Track Mark 8 #9158015 待售

网址复制成功!

单击可缩放

ID: 9158015

晶圆大小: 8"

优质的: 1997

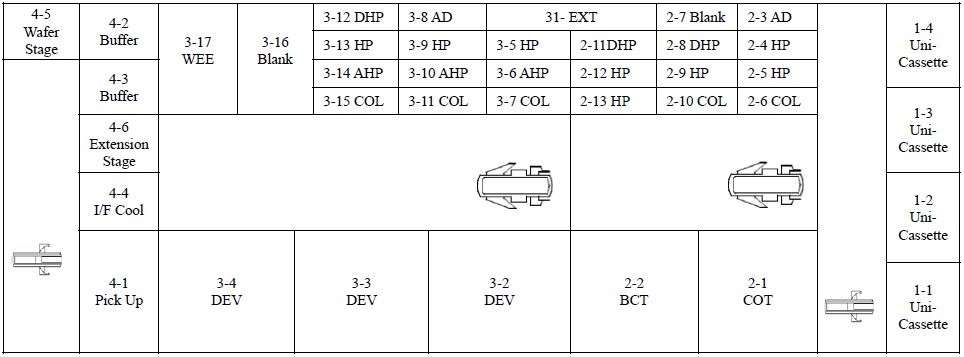

(2) Coater / (3) Developer system, 8"

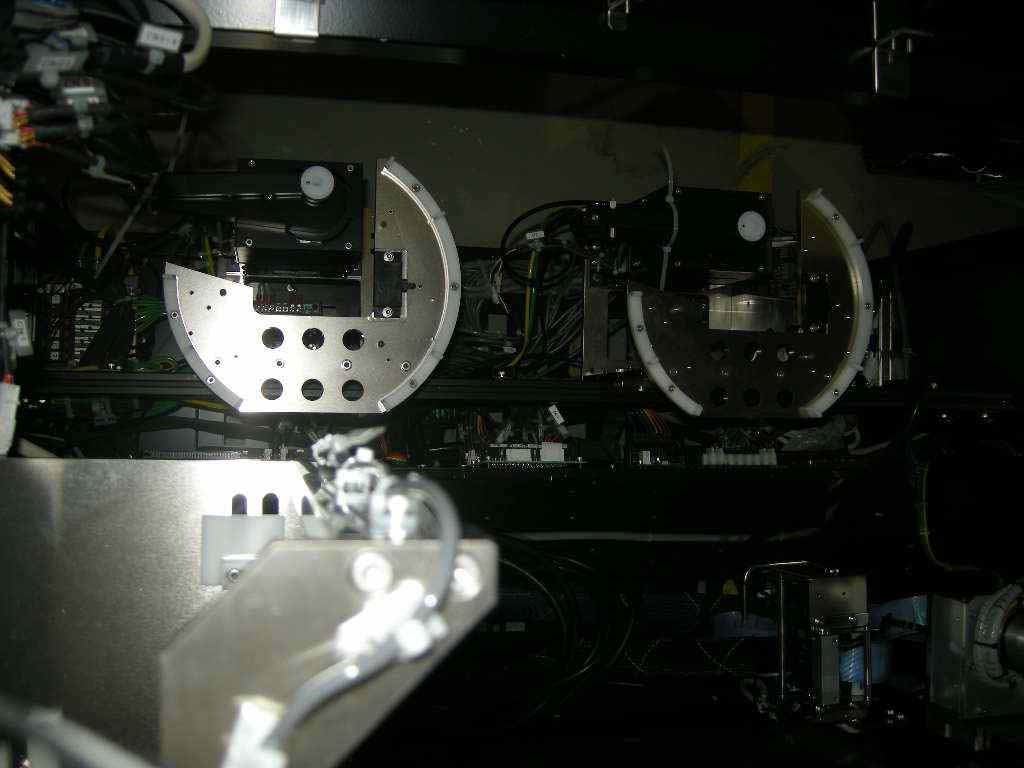

Dual block

Silicon substrate wafer

Wafer flow: Right to left

CSB Unit at right

Interface station unit at left

(2) Process blocks:

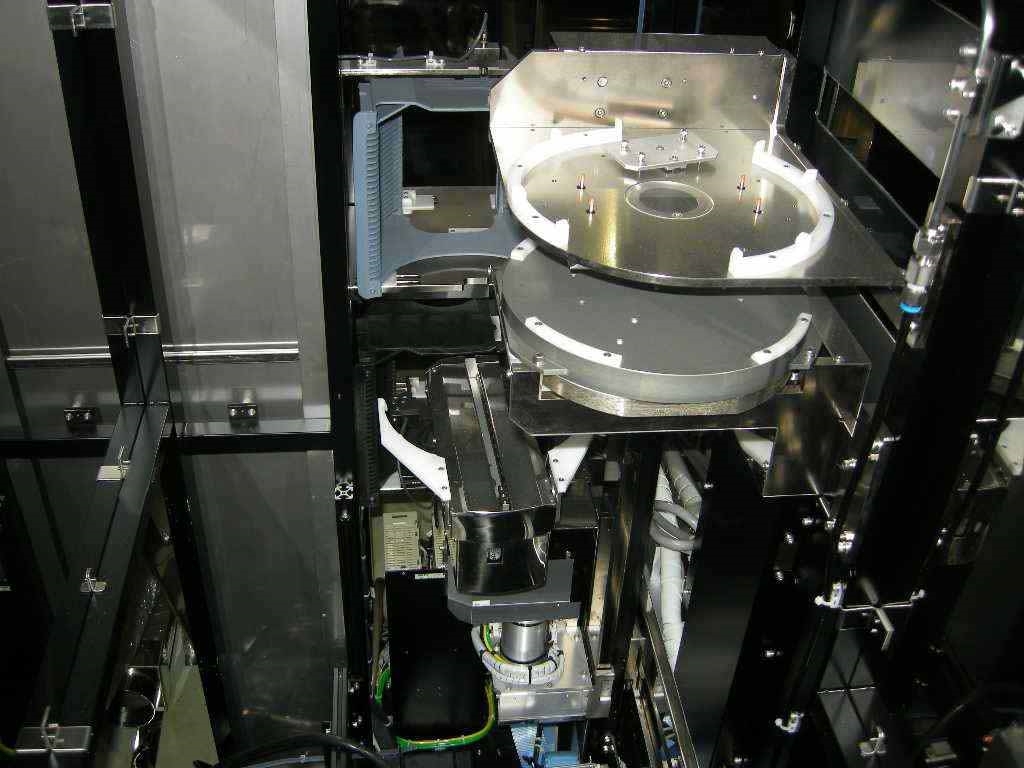

Cassette station block (CSB):

FC-9801F Controller

Stage / Indexer:

Non SMIF / Open uni-cassette

Cassette station (CS)

Cassette station arm (CSA)

PSB / Process station block (Spin units):

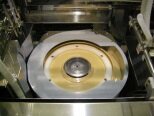

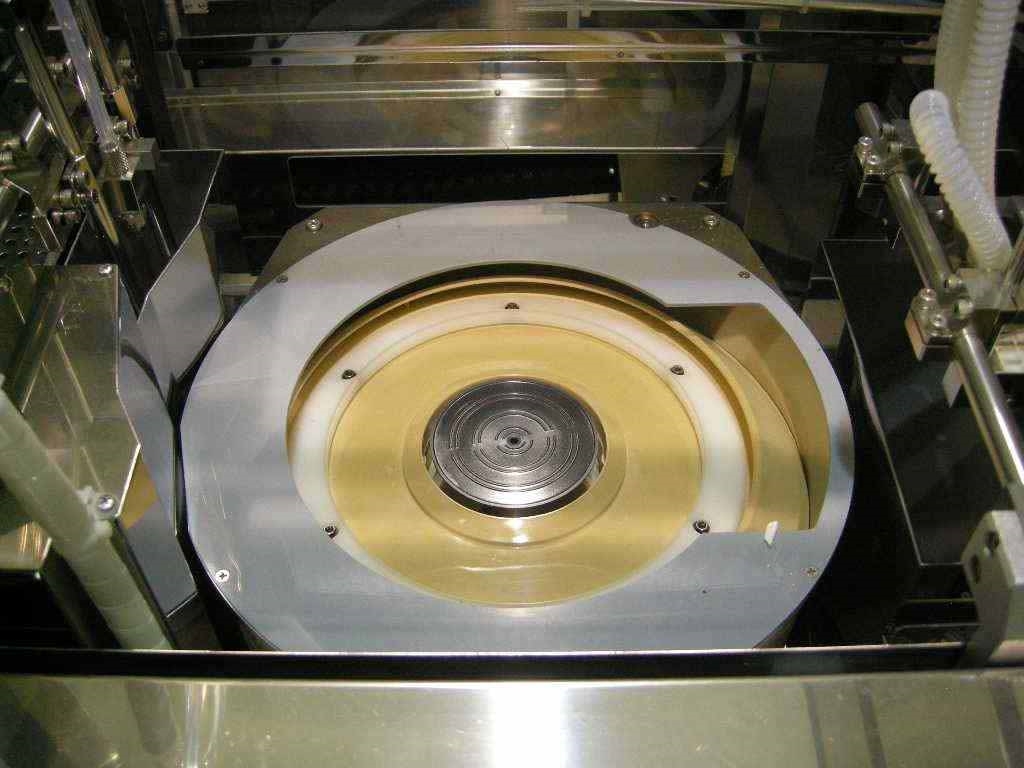

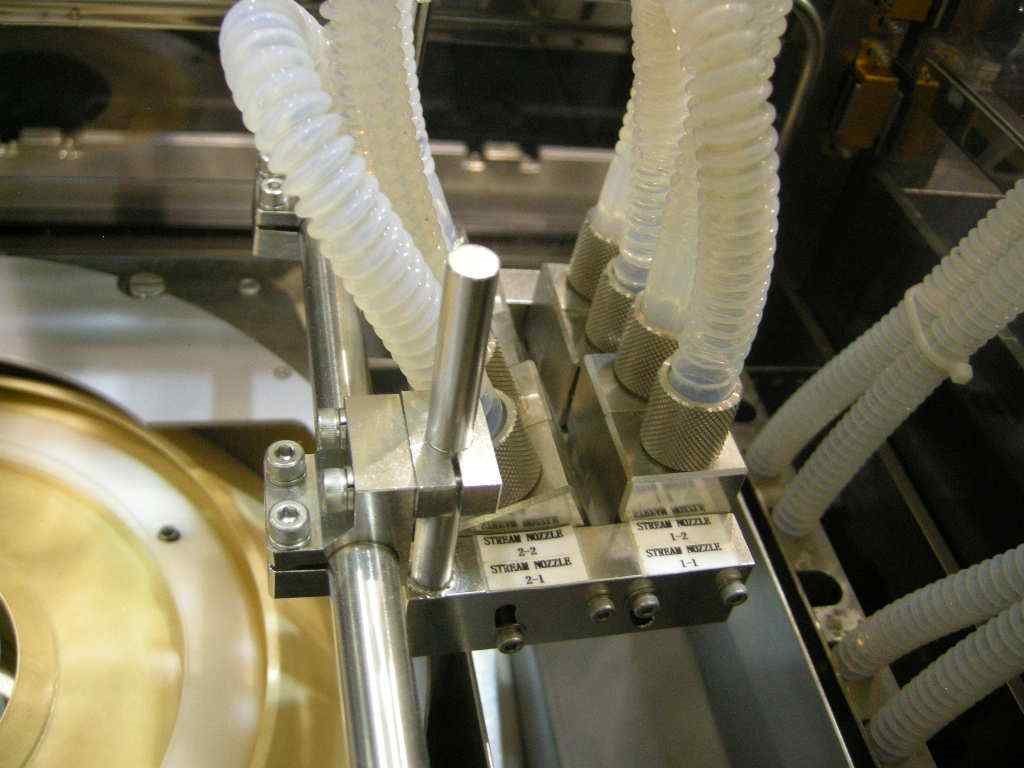

2-1 Standard photo resist coat unit:

(3) Photo resist dispense nozzles

(3) IWAKI Bellows pumps

Solvent pre-wet reduced resist coat (RRC) nozzle

Side rinse nozzle (Programmable side rinse EBR)

Dual back rinse nozzles

Photo resist temperature control

Motor flange temperature control

Photo resist drain type: Direct gravity drain type

(6) Photo resist bottles in external chemical supply systems

Photo resist auto exchange

Auto dummy dispense system

2-2 Bottom layer coat (BCT) unit:

(3) Bottom layer coat (BCT) dispense nozzles

(3) IWAKI Bellows photo resist pumps

Solvent pre-wet reduced resist coat (RRC) nozzle

Side rinse nozzle (Programmable side rinse EBR)

Dual back rinse nozzle

Photo resist temperature control

Motor flange temperature control

Photo resist drain type: Direct gravity drain type

Photo resist bottle: (6) External photo resist supply system

Photo resist auto exchange

Auto dummy dispense system

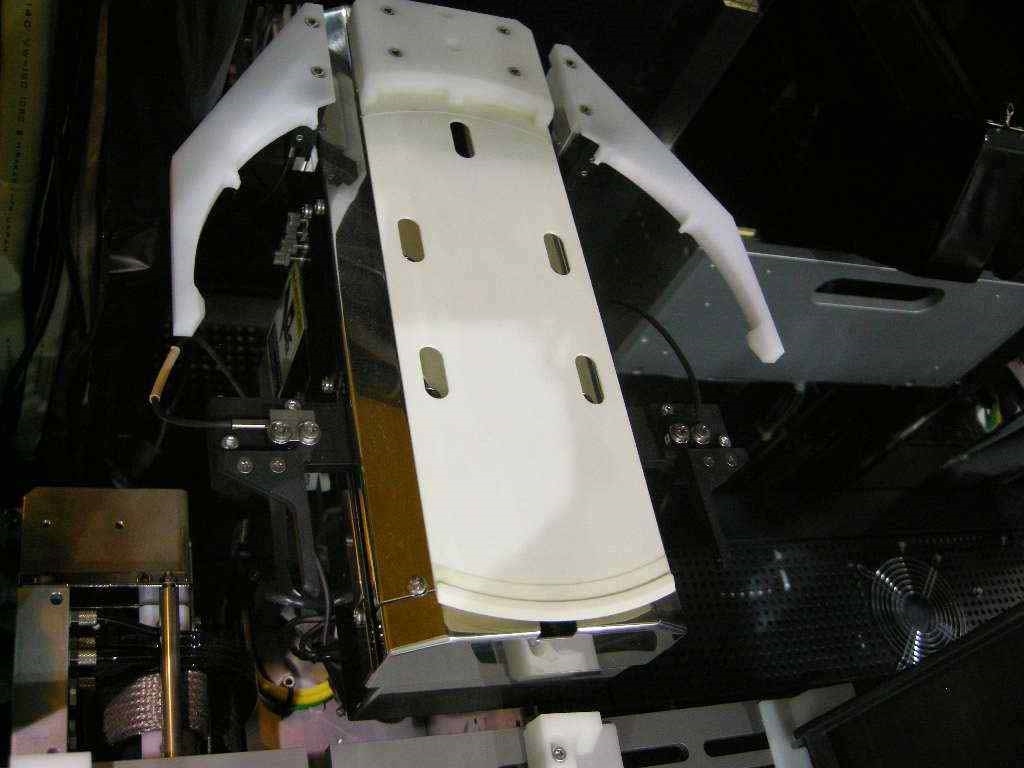

Process block robotics arm (PRA)

Adhesion unit (AD)

(5) Hot plate oven units

(2) Dehydration hot plate (DHP) oven units

(2) Cool plate units

Process station block (Spin units):

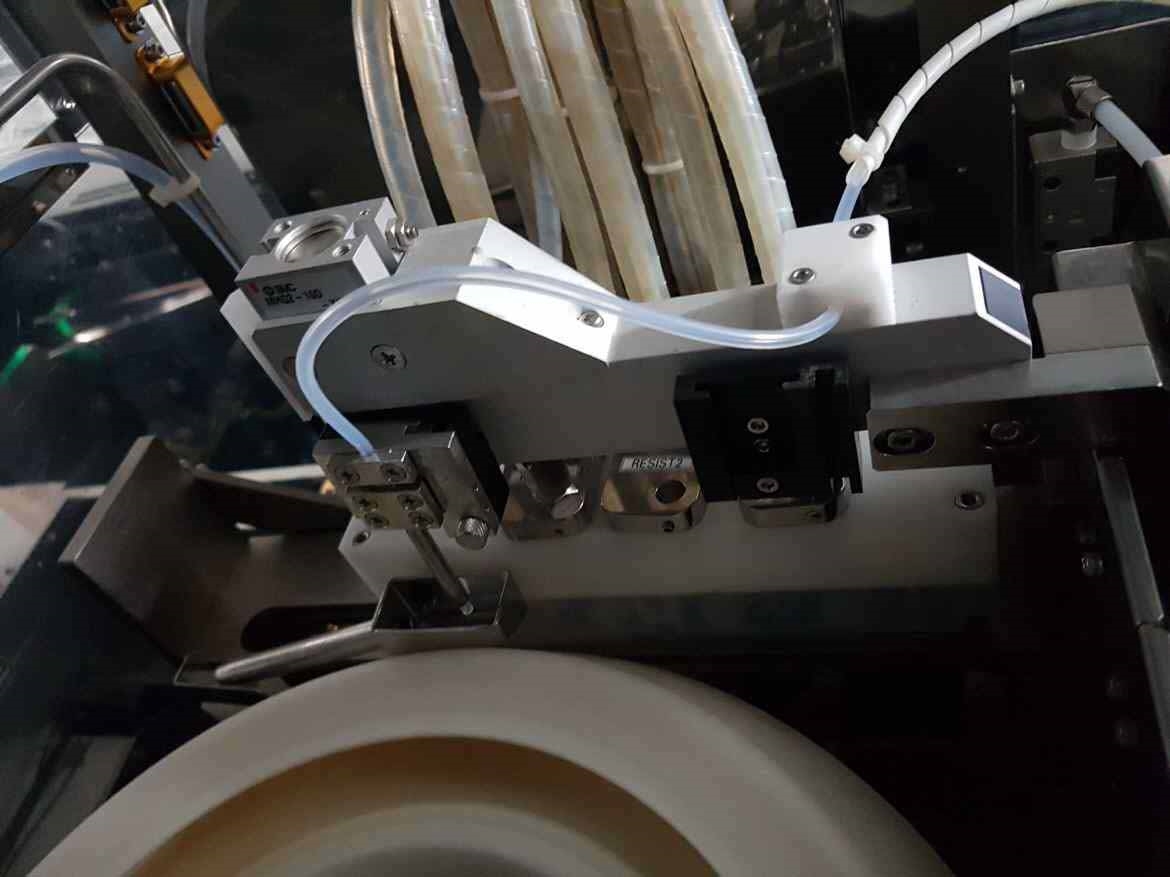

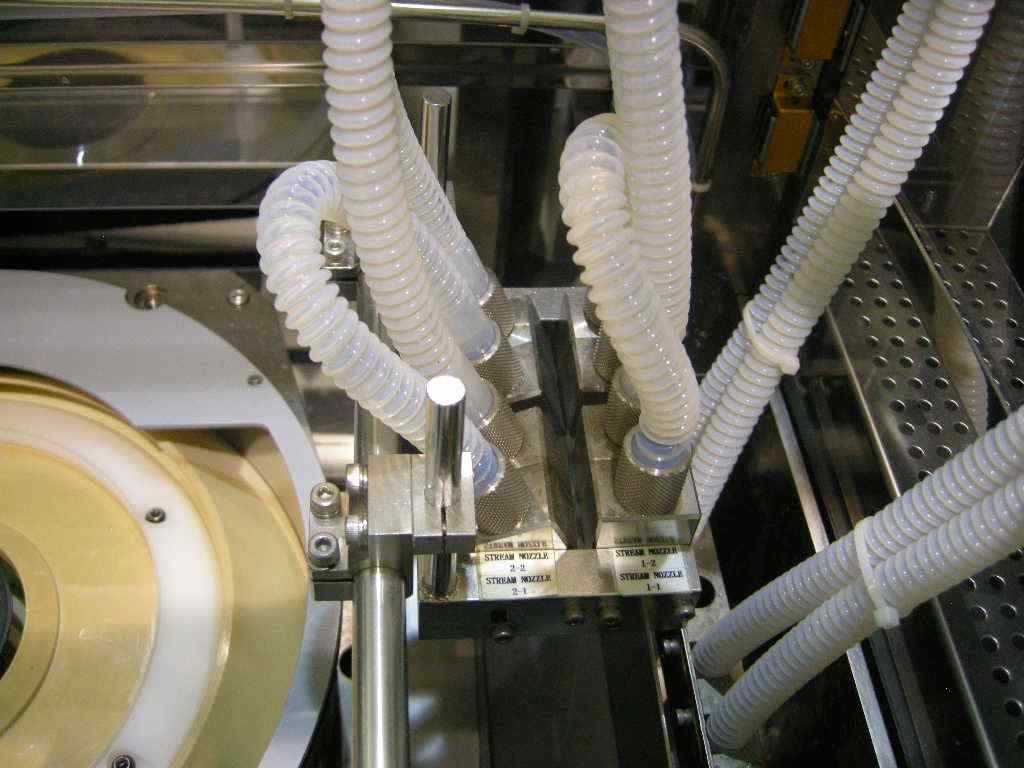

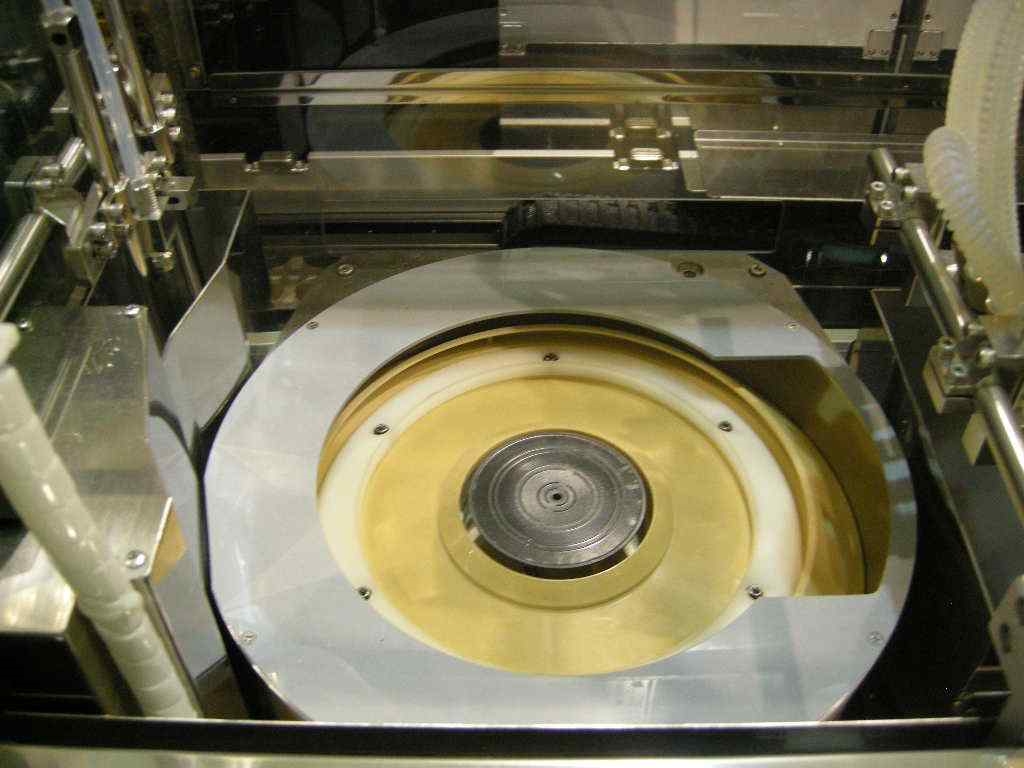

3-2, 3-3, 3-4 Develop units:

(4) Stream nozzles at (4) Stream nozzle blocks

Rinse nozzles:

(2) Stream type

Spray type

Dual back rinse nozzles

Develop temperature control

Motor flange temperature control

Drain type: Direct gravity drain type

Auto damper

Auto dummy dispense system

Process block robotics (PRA) Arm

Adhesion unit

(3) Hot plate oven units

Dehydration hot plate (DHP) oven unit

(3) Air-purge hot plate (AHP) oven units

(3) Cool plate units

Extension unit

Wafer edge exposure (WEE) unit

Interface station block (IFB):

Interface arm (IFA)

Interface for ASML PAS Series Stepper

(2) Buffers

Pick-up system

Interface cool

Extension stage

Wafer stage

Temperature and humidity controller:

TEAM KOREA TK-TH8T4

2-Cup control capacity for 2 Coat units

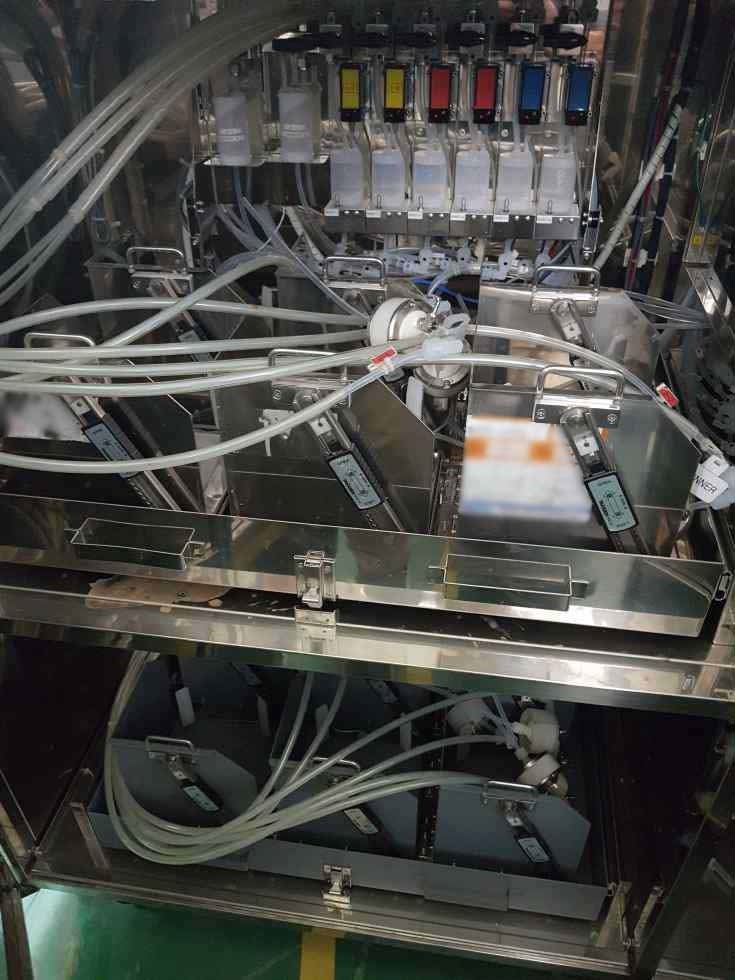

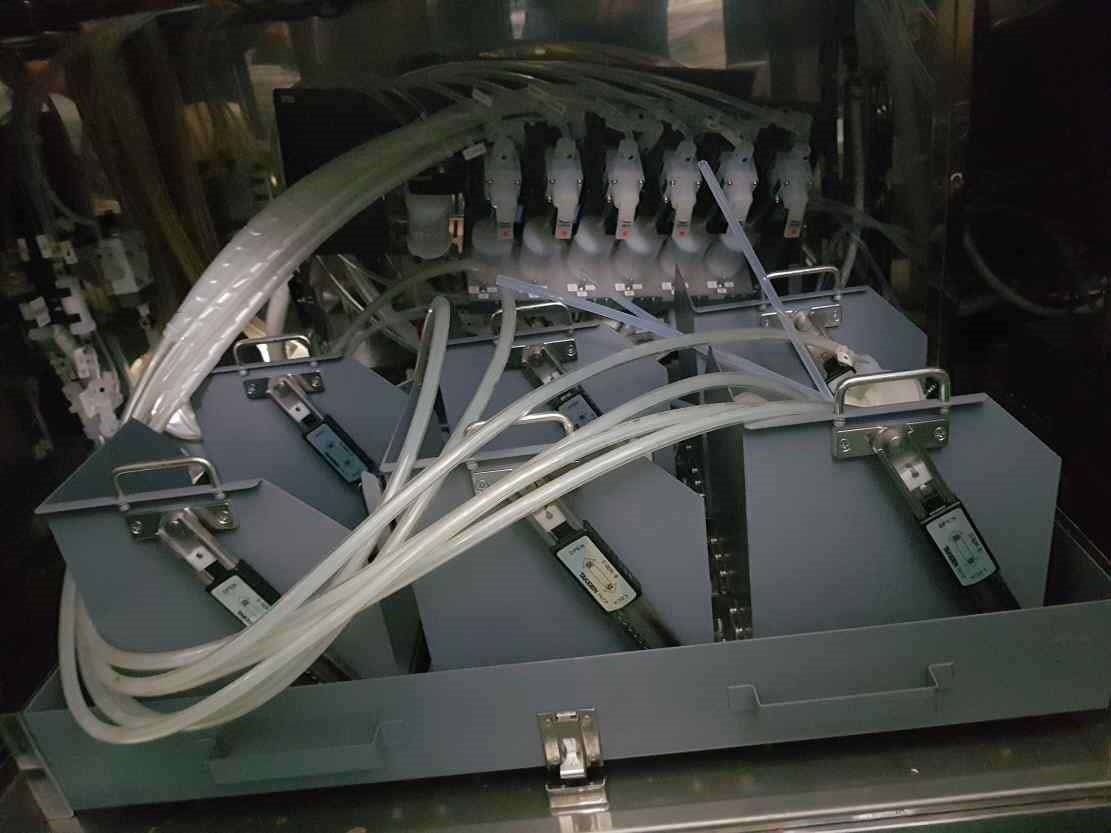

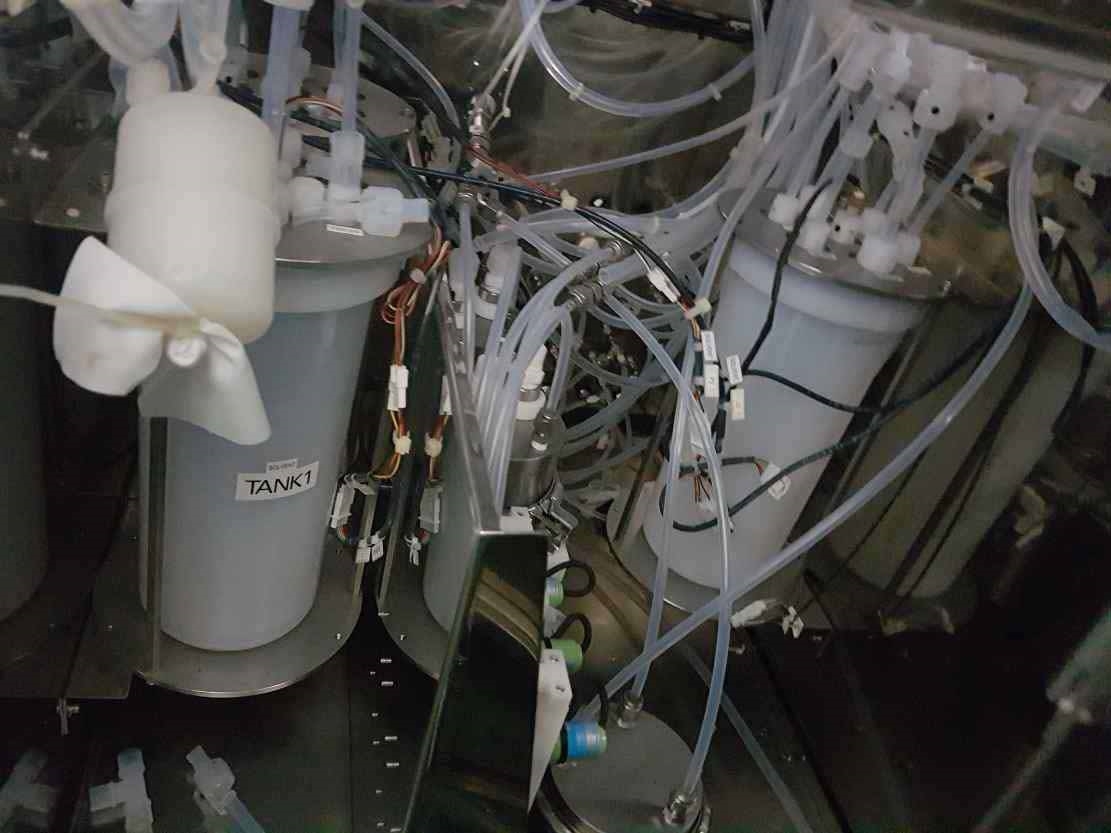

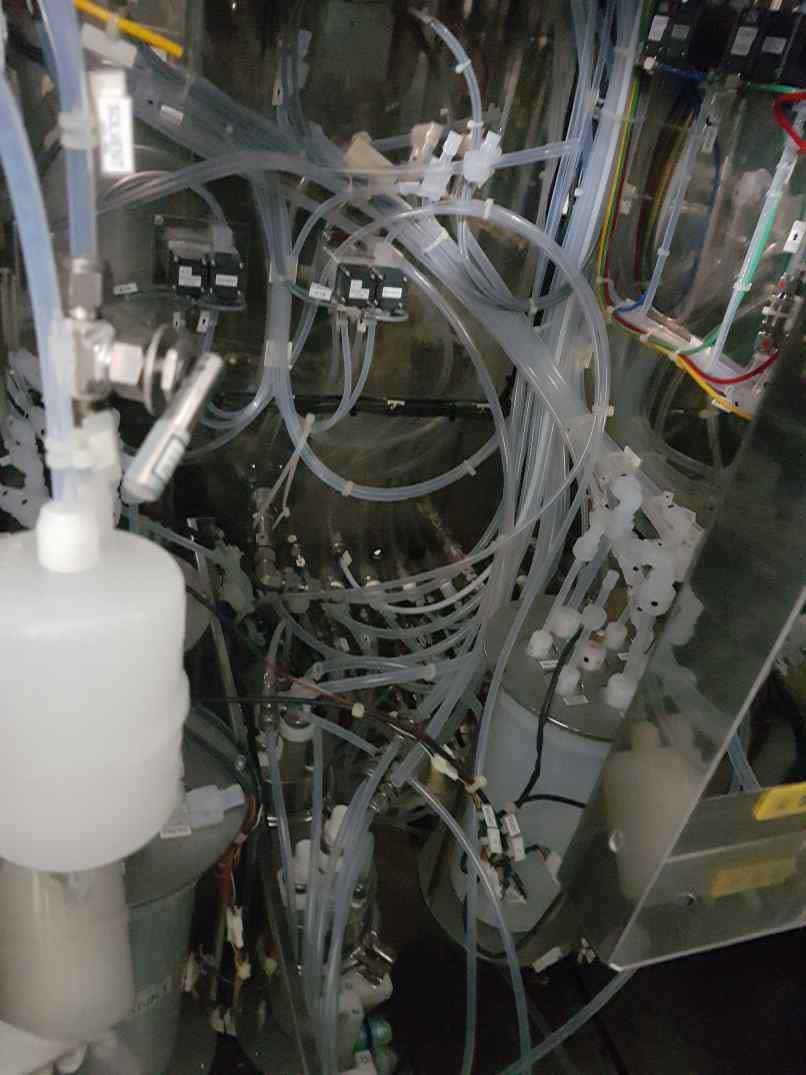

External chemical supply system:

Solvent supply system:

Solvent chemical type

CSS Bulk-fill to auto supply system

With (2) Buffer tanks: Auto switch-off / Exchange

Develop supply system:

Develop solution chemical type

CSS Bulk-fill to auto supply system

With (2) Buffer tanks: Auto switch-off / Exchange

Photo resist supply system for 2-1 Coat and 2-2 BCT

6-Bottles of manual supply type

Auto exchange system

HMDS Supply system:

HMDS Chemical type

CSS Bulk-fill to auto supply system with bubbling jar

HMDS Supply system

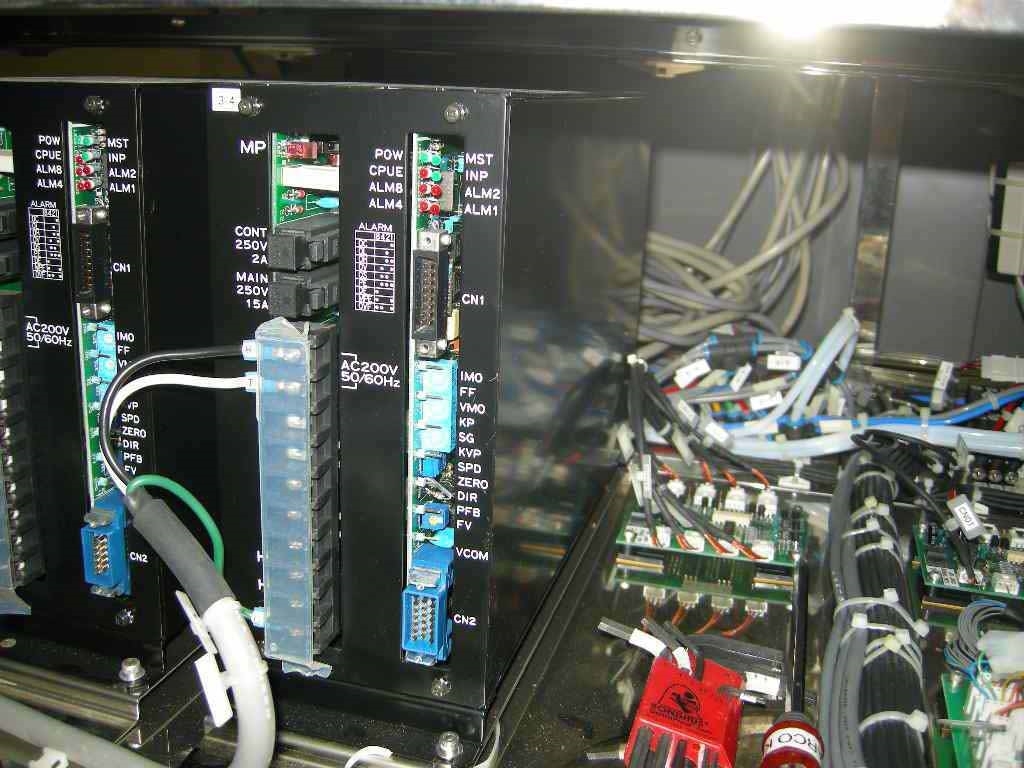

Themo controller:

External chemical supply system: (2) TEL / TOKYO ELECTRON SMC Multi controller

MAX 16 Channel capacity: 12-Channels for (2) Process

SMC Multi thermo controllers:

(6) SMC Circulators: Chilling channels

2-1 COT Unit

2-2 BCT Unit

Stream nozzle block:

Block 1 and 3: 3-2, 3-3 DEV

Block 2 and 4: 3-4 DEV

(5) Motor flanges

(6) SMC Thermo controllers: Chilling channels

2-9 COL

2-10 COL

3-7 COL

3-11 COL

3-15 COL

4-4 I/F COL

(4) Robots:

CS Arm

(2) Main arm robots

Interface arm

Power transformer AC cabinet: 208 VAC, 3-Phase, 50/60 Hz

1997 vintage.

TEL(TOKYO ELECTRON)TEL/TOKYO ELECTRON CLEan Track Mark 8是一款用于製造电路板的光敏设备。该系统能够进行各种光刻过程,包括旋转涂层、软烘烤、面膜对准、喷涂和硬烘烤。干净的轨道可以实现可重复和准确的结果,从而帮助创造高产率。TEL Clean Track Mark 8旨在帮助减少清洁空间停机时间并提高工作效率。它具有耐用、可靠的防静电底盘和"no-ccd"对齐单元,可将对齐时间缩短一半。此外,该机还配备了触摸面板液晶显示屏,这使得导航工具的功能更加容易。该资产包括两种独特和先进的烘烤技术,以提高清洁度和工艺精度。首先是分裂烘烤,将烘烤过程分成两部分,降低污染风险,优化温度稳定性。二是溷合烘烤,可以完全烘烤晶圆,而不会将基材分离成任务。TOKYO ELECTRON Clean Track Mark 8採用特别设计的喷嘴和清洁剂,能够快速清除抗拒残留物,导致更清洁的晶片,同时大幅减少化学废弃物的产生。特殊的涂层功能可将化学用量和清洁时间减少70%之多,陶瓷头喷嘴有助于减少总颗粒数量,而高精度的无接触跟踪有助于提高对准精度。此外,该模型是可改造的,它允许与各种光刻胶系统兼容。总体而言,Clean Track Mark 8使用先进技术,使用户能够获得可重复和一流的结果,同时最大限度地减少化学品、能源和停机时间的使用。它被设计成一种高效的光敏设备,帮助用户在保持成本效益的生产的同时达到最大产量。

还没有评论