二手 TEL / TOKYO ELECTRON Clean Track Mark 8 #9165442 待售

网址复制成功!

单击可缩放

ID: 9165442

晶圆大小: 8"

优质的: 1997

(2) Coater / (2) Developer system, 8"

Single block

Open cassette

Interface for NIKON NSR 2205 EX14C

Silicon substrate wafer

Wafer flow: Left to right

CSB Unit at right

Interface station unit at left

(2) Process blocks: Single block system

Cassette station block (CSB):

FC-9821KE Controller

Stage / Indexer:

Non SMIF / Open uni-cassette

Cassette station (CS)

Cassette station arm (CSA)

Process station block (Spin units):

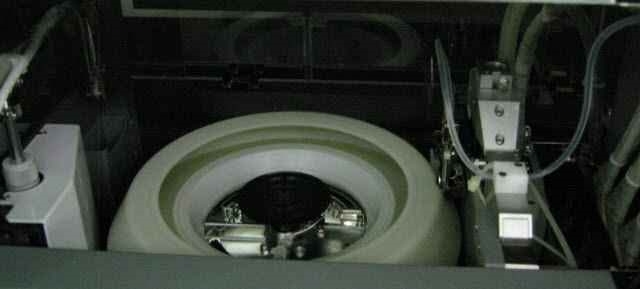

2-1 Standard photo resist coat unit:

(3) Photo resist dispense nozzles

(3) IWAKI Bellows pumps

Solvent pre-wet reduced resist coat (RRC) nozzle

Side rinse nozzle (Programmable side rinse EBR)

Dual back rinse nozzles

Photo resist temperature control

Motor flange temperature control

Photo resist drain type: Direct gravity drain type

Auto dummy dispense system installed

Photo resist bottle: (6) External chemical supply system

2-2 Anti-reflection coat unit:

(3) Photo resist dispense nozzles

(3) IWAKI Bellows photo resist pumps

Solvent pre-wet reduced resist coat (RRC) nozzle

Side rinse nozzle (Programmable side rinse EBR)

Dual back rinse nozzles

Photo resist temperature control

Motor flange temperature control

Photo resist drain type: Direct gravity drain type

Auto dummy dispense system installed

Photo resist bottle: (6) External chemical supply system

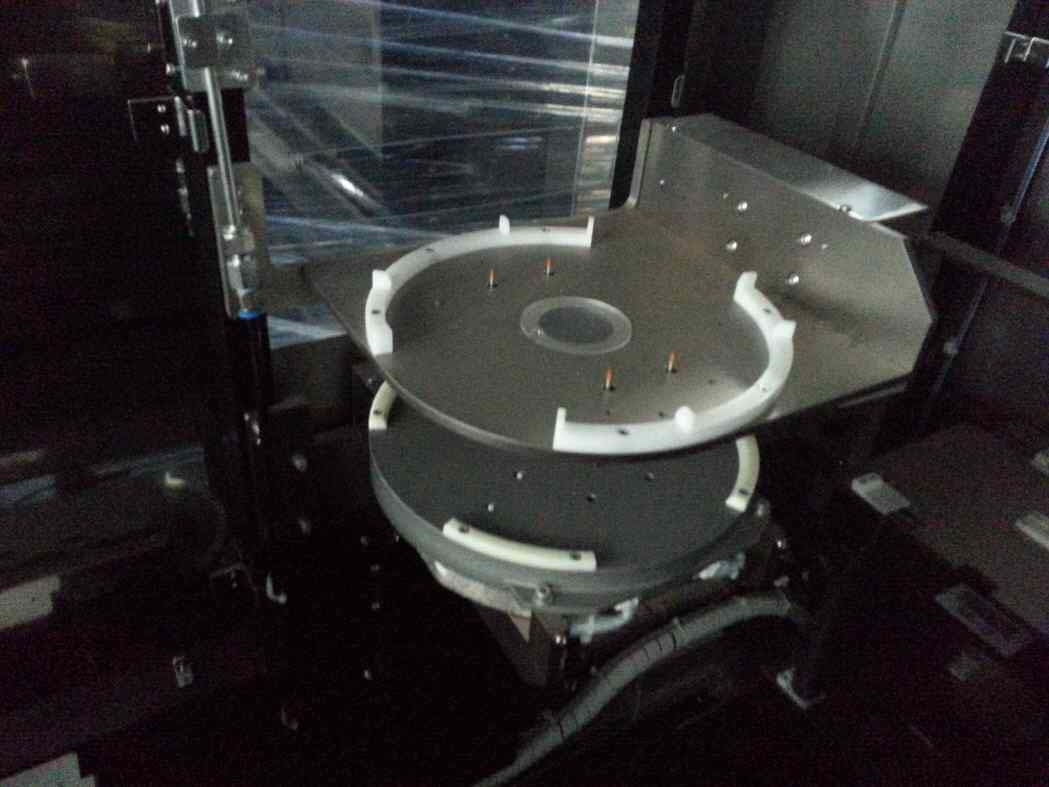

2-3 and 2-4 Develop units:

(4) Stream nozzle blocks

(4) Stream nozzles

(2) Rinse nozzles: Stream type

Dual back rinse nozzles

Develop temperature control

Motor flange temperature control

Drain type: Direct gravity drain type

Auto damper

Auto dummy dispense system

Process block robotics arm (PRA)

Adhesion unit

(10) Hot plate oven units

(2) Air-purge hot plate (AHP) oven units

(7) Cool plate units

Wafer edge exposure (WEE) unit

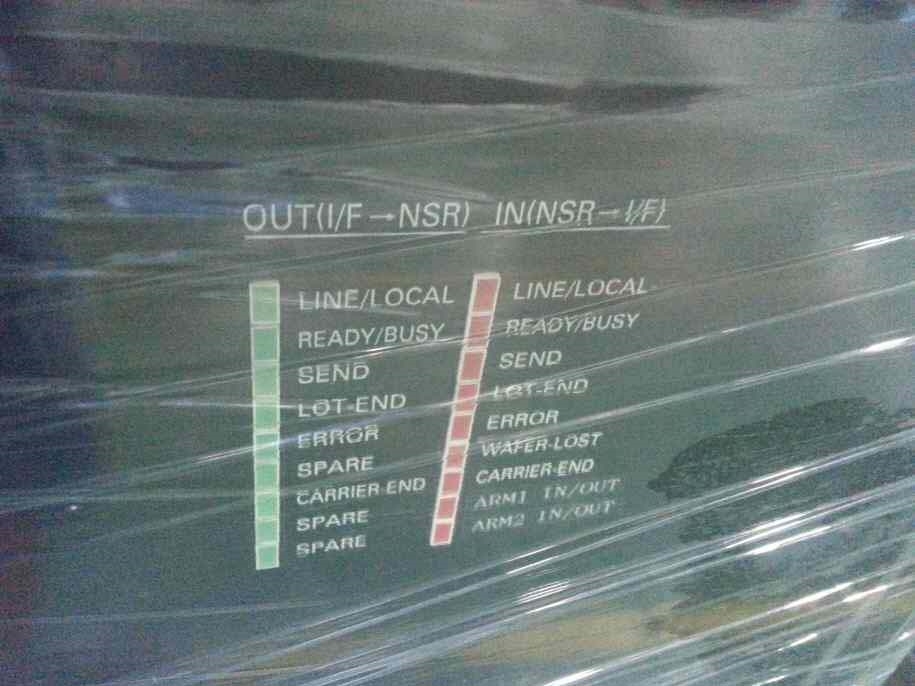

Interface station block (IFB):

Interface arm (IFA)

(2) Buffers

Pick-up system

Interface cool

Extension stage

Wafer stage

Temperature and humidity controller:

SHINWA T&H-CPC

2-Cup control capacity for (2) Coat units

External chemical supply system:

Solvent supply system for (2-1) COT and (2-2) ARC:

Solvent chemical type

Bulk-fill central chemical supply (CSS) type

With (2) 3-Liter teflon buffer tanks

Develop supply system for 2-3 and 2-4 Develop units:

Develop solution chemical type

Bulk-fill central chemical supply (CSS) type

With (2) 3-Liter teflon buffer tanks

(2) Photo resist supply systems:

6-Bottles of manual supply type

Auto switch-off / Exchange installed

HMDS Supply system:

HMDS Chemical type

Bulk-fill central chemical supply (CSS) type

With 3-Liter teflon buffer tanks for AD unit

External chemical supply system / Cabinet: (2) SMC Multi thermo controller units

SMC Circulator pumps and thermo controller

With 7-Channels:

2-1 COT

2-2 ARC

Motor flanges: 2-1 COT and 2-2 ARC

2-8 COL

2-12 COL

2-16 COL

2-19 COL

SMC Circulator pumps and thermo controller

With 7-Channels:

1 and 3 Stream nozzle blocks: 2-3

2 and 4 Stream nozzle blocks: 2-4

(2) Motor flanges at 2-3 and 2-4 DEV

2-20 COL

2-23 COL

2-24 COL

3-4 I/F COL

(3) Robots:

CS Arm

Main arm robots

Interface arm

Power transformer AC cabinet: 208 VAC, 3-Phase, 50/60 Hz

1997 vintage.

TEL/TOKYO ELECTRON CLEAN Track Mark 8是为满足当今超高可靠性和高精度电路板的要求而开发的光刻胶系统。Mark 8采用了先进的超声波接触清洁(UCC)方法,配备了两步式的"吹气清洗和扫描清洗"工艺。Airblow Cleaning process uses a high-speed air flow to remove dust, dust, and contains up at a some size.它利用强制气流清洁表面,而不会对基板造成任何损害或应力。"扫描清洁"过程采用了使用旋转刷子的往复式清洁方法。这将清除空气吹扫过程后残留的小污染物。Mark 8还包含一些其他功能,以提高性能和输出。其中包括使用特定密度清洁器(SDC)、CCD相机进行缺陷检测、板室温度控制、硬件和软件警报监控、Shimura/Kitta缺陷检测、自动化学水平控制和卷带式芯片粘度控制。Mark 8还具有额外的灵活性和可定制的板基级,使其能够处理高应变和低应变传感器基板,以及标准化和非标准化基板。此外,该工具还集成了高度感应传感器,从而减少了在加工过程中出现颗粒污染的机会,并提高了性能。在当今高精度电路板时代,TEL Clean Track Mark 8光刻系统满足了客户的性能和可靠性需求。它具有先进的UCC功能和几个附加功能,有助于为客户提供一贯清洁、高质量的基板。凭借Mark 8的多功能性和高级功能,它能够满足最苛刻的要求,确保无与伦比的性能。

还没有评论