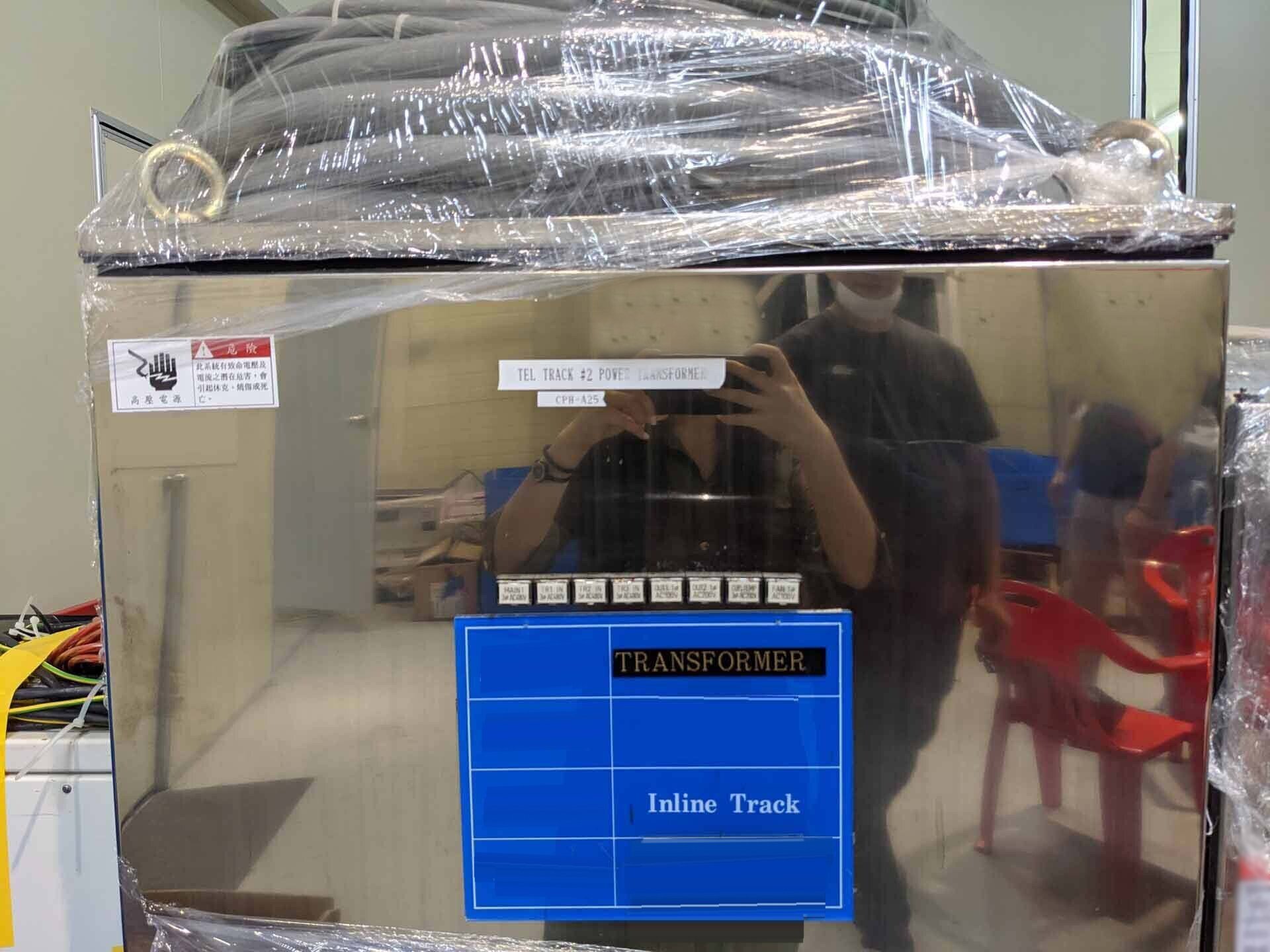

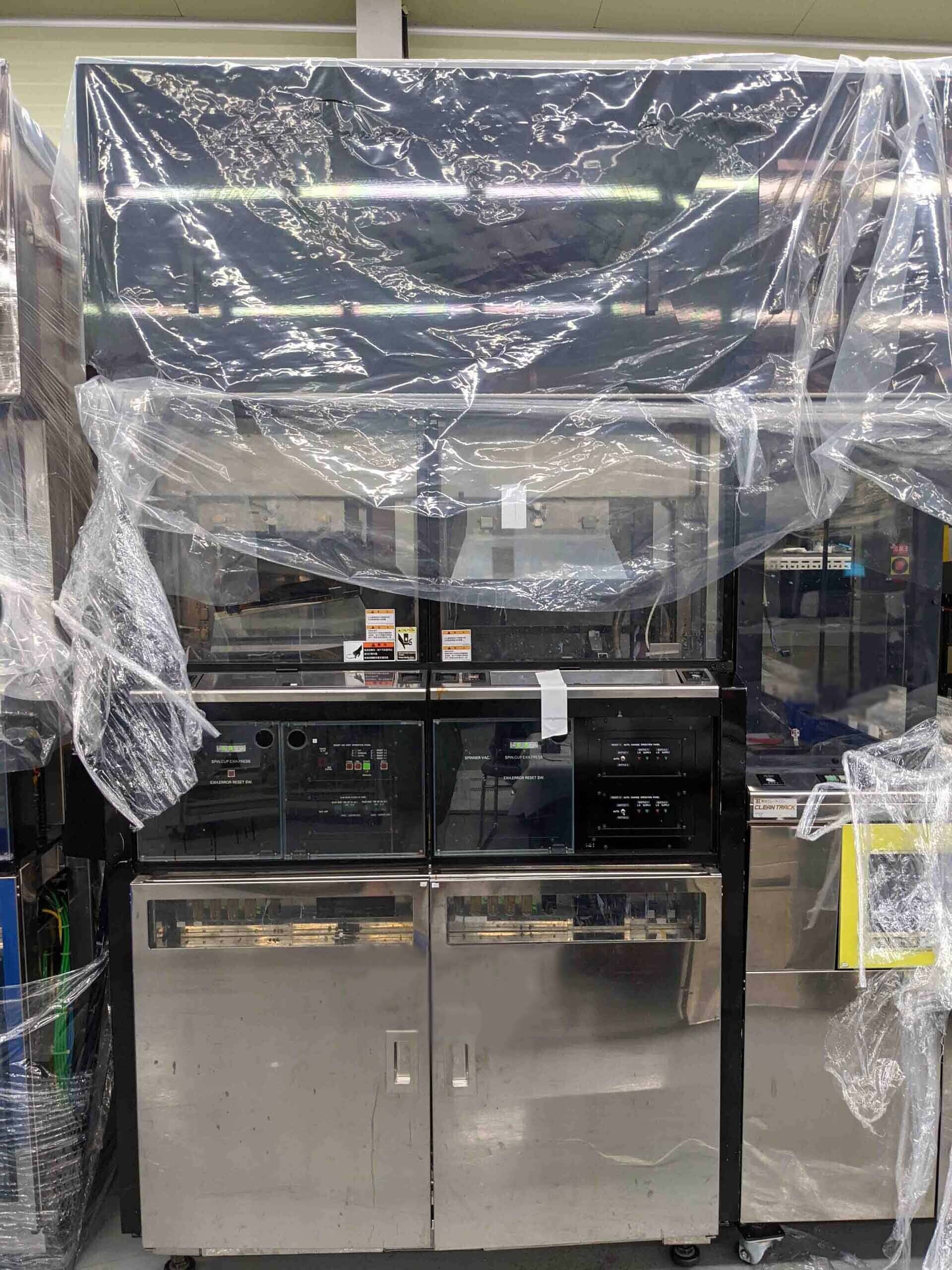

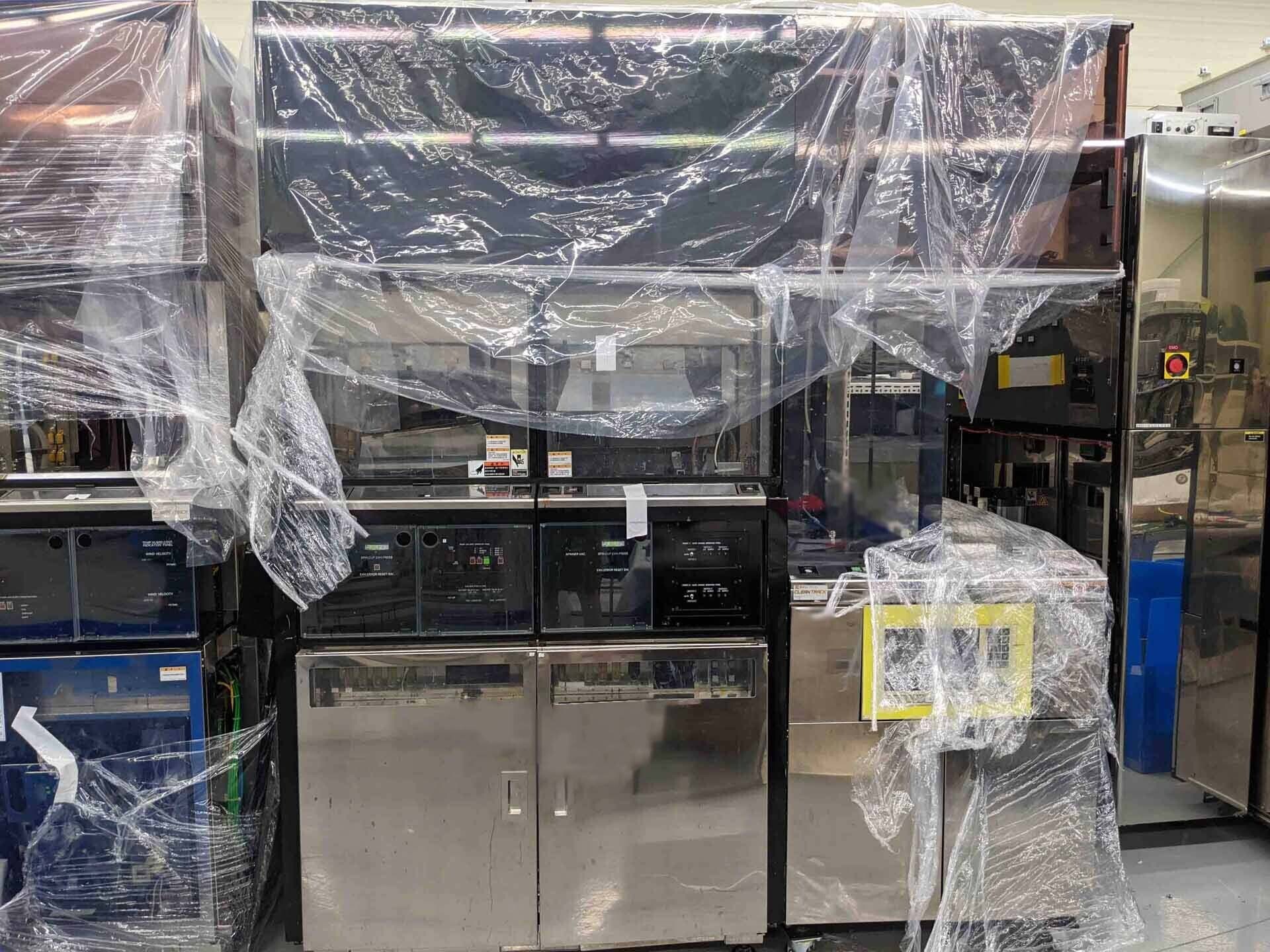

二手 TEL / TOKYO ELECTRON Clean Track Mark 8 #9392817 待售

网址复制成功!

单击可缩放

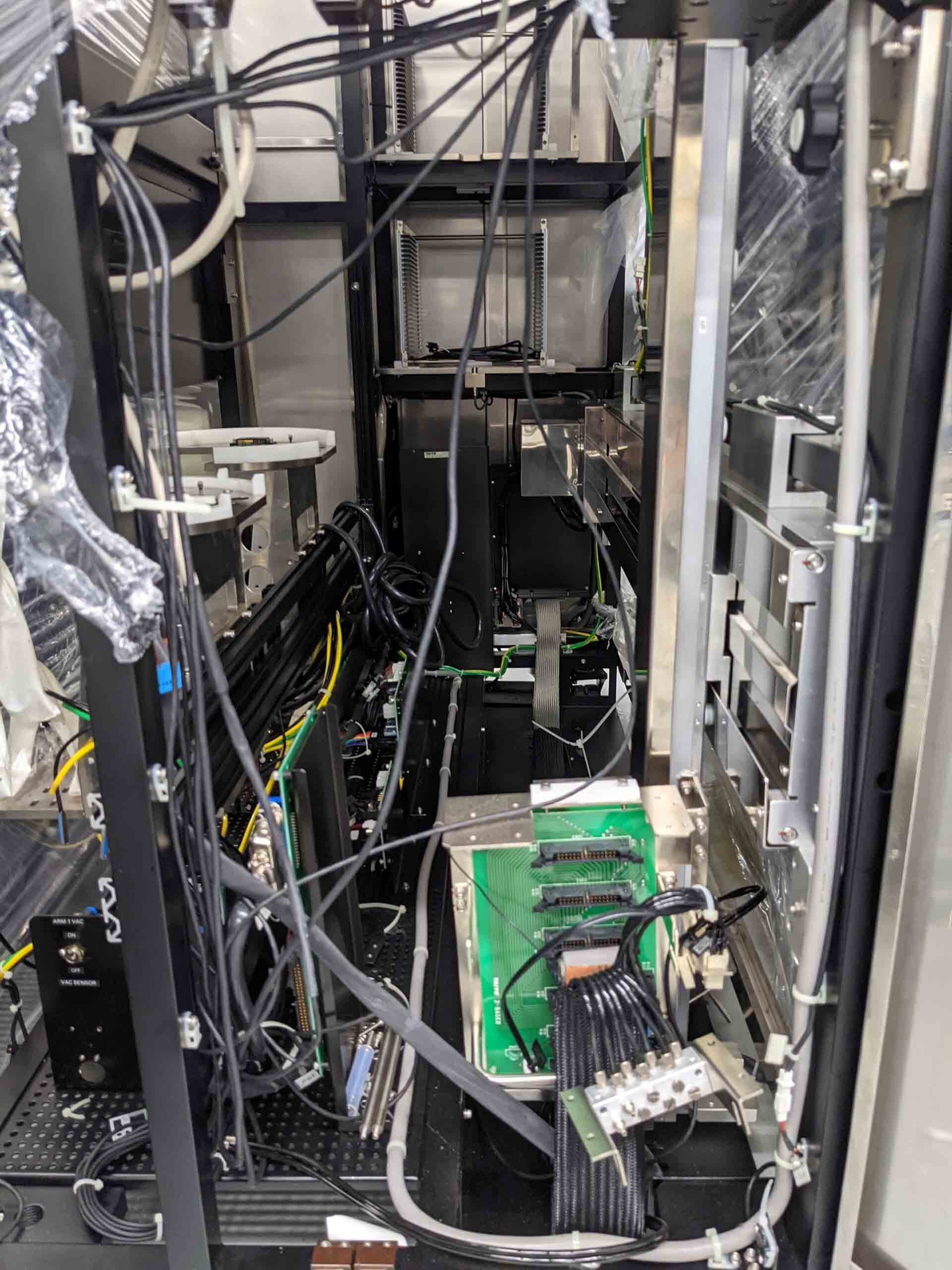

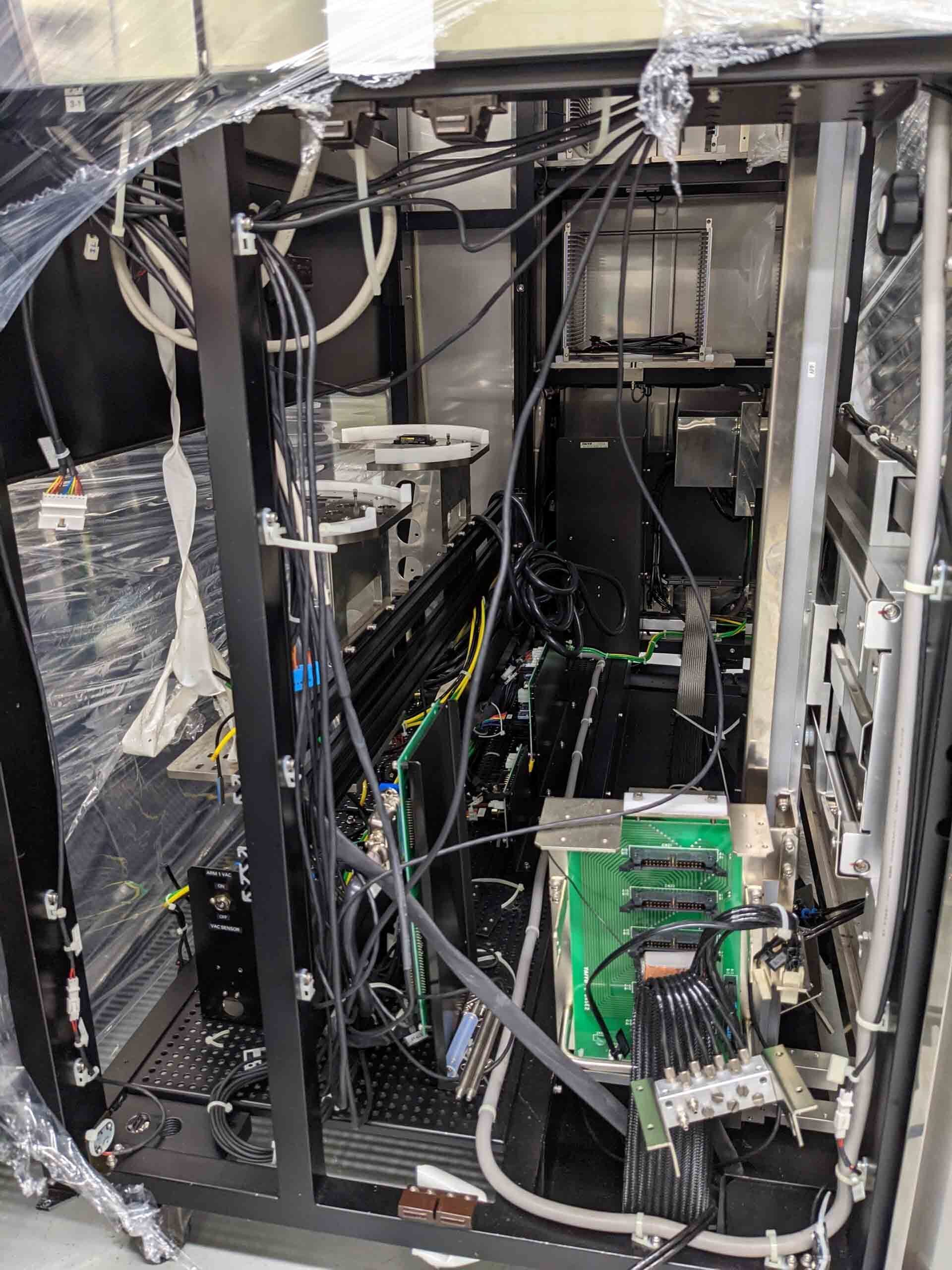

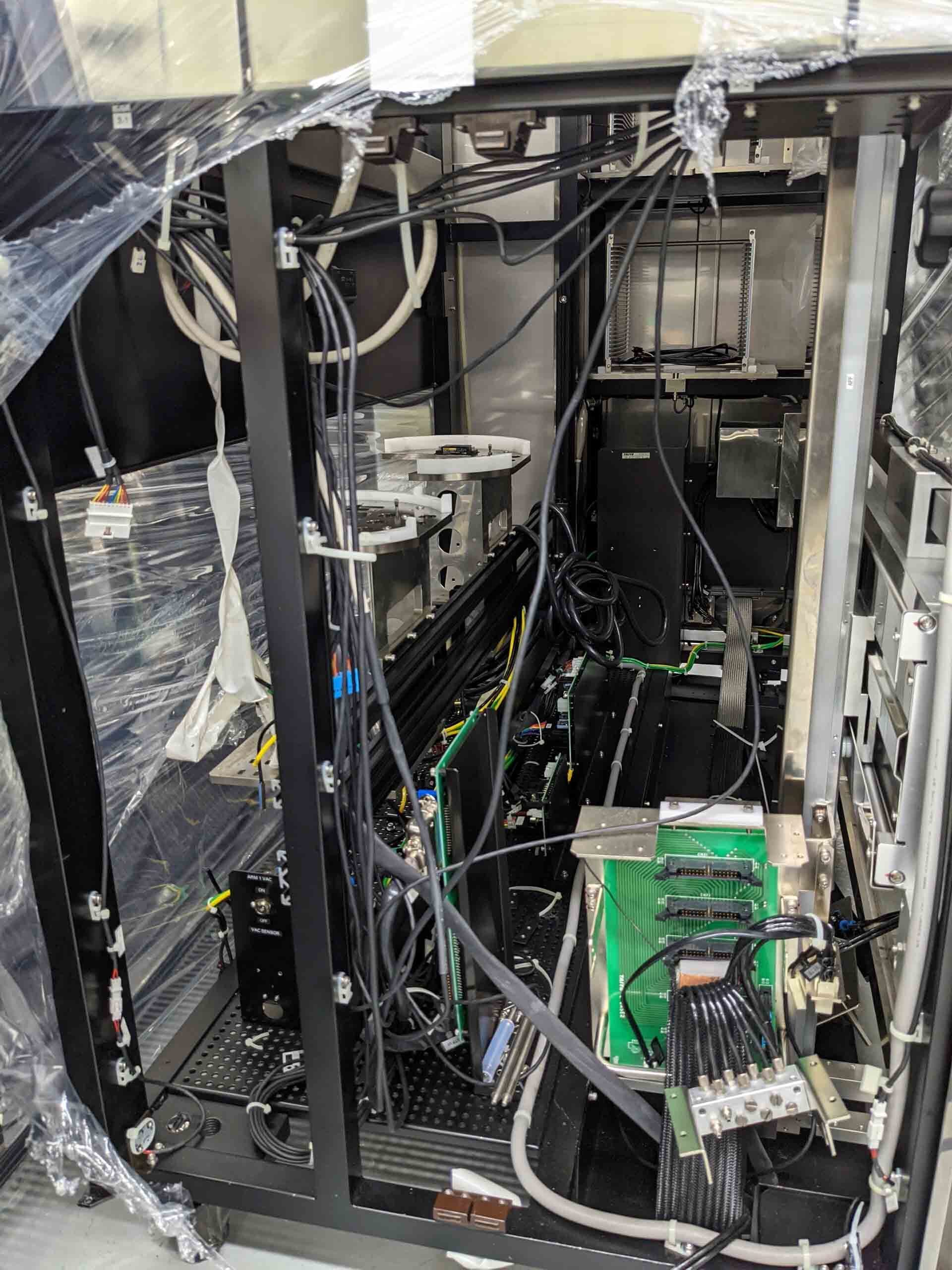

ID: 9392817

晶圆大小: 8"

优质的: 1995

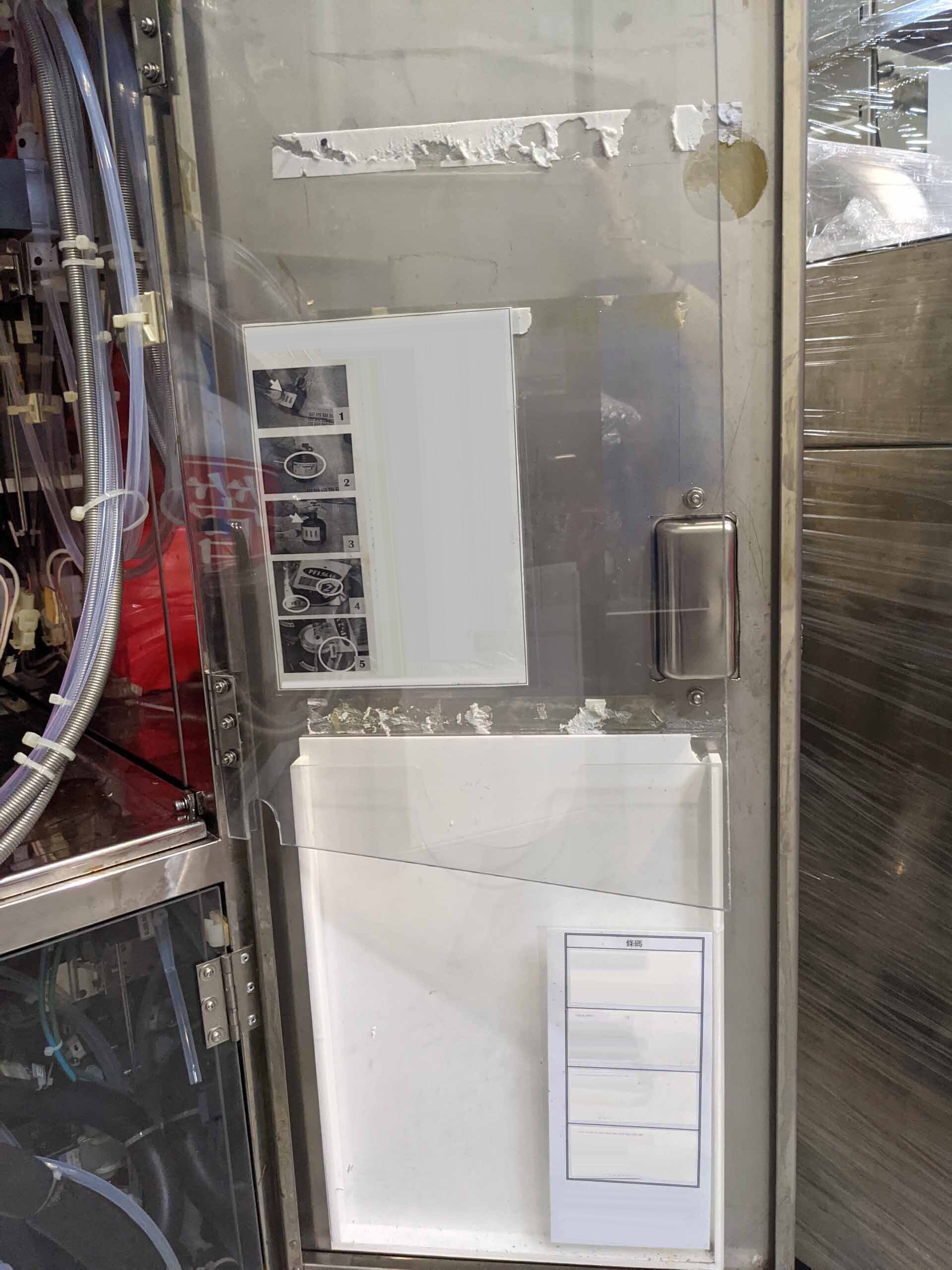

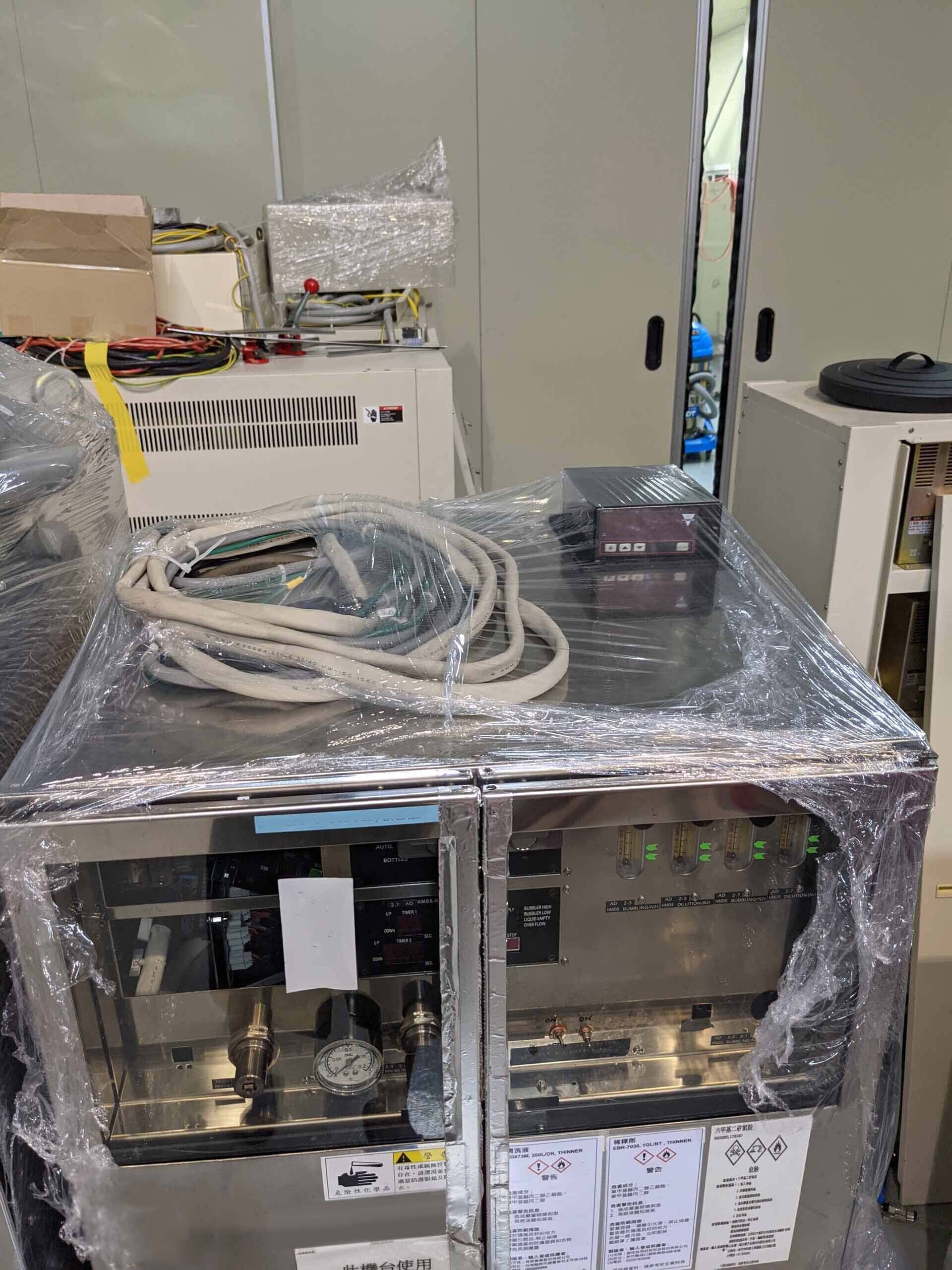

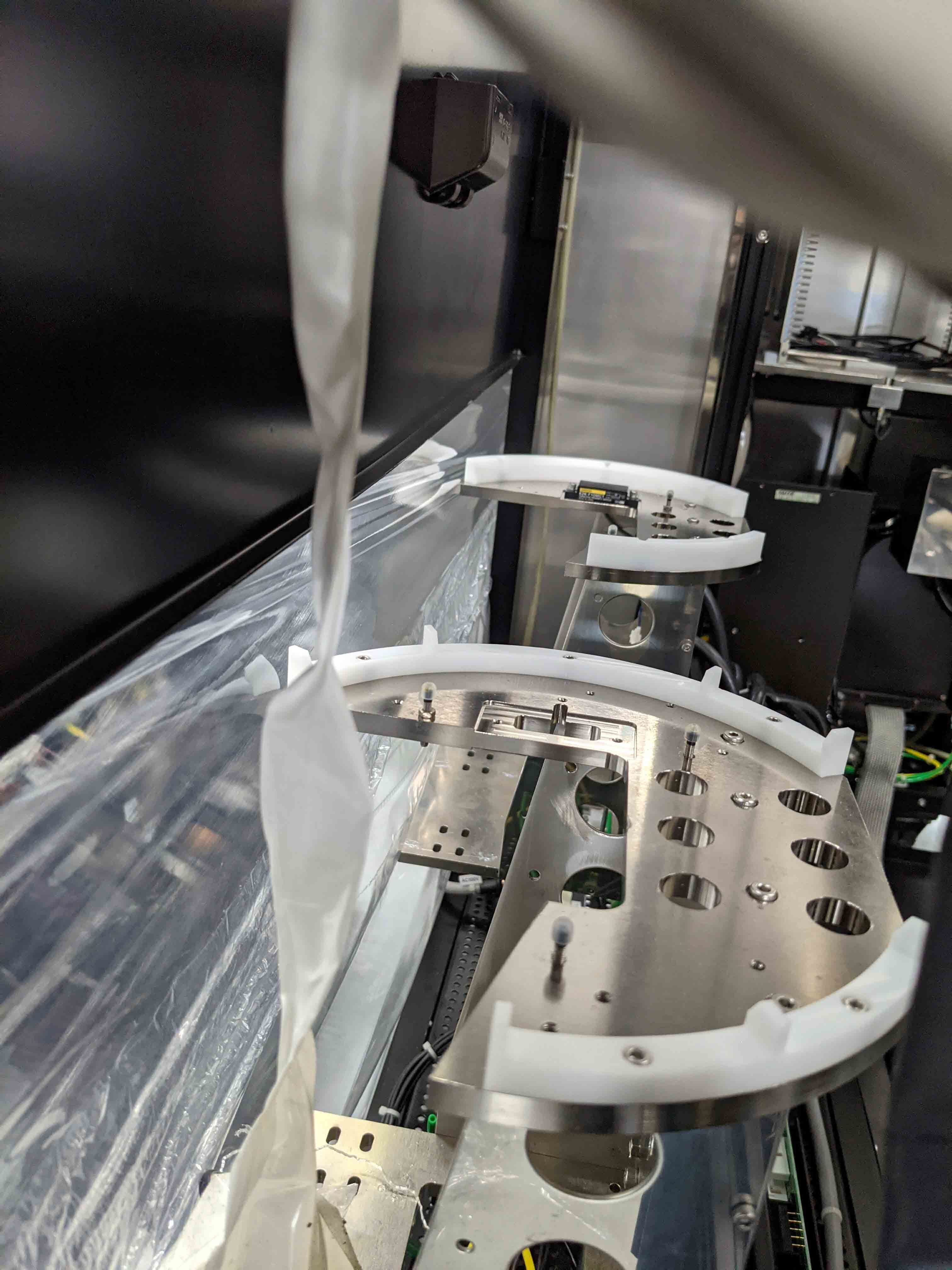

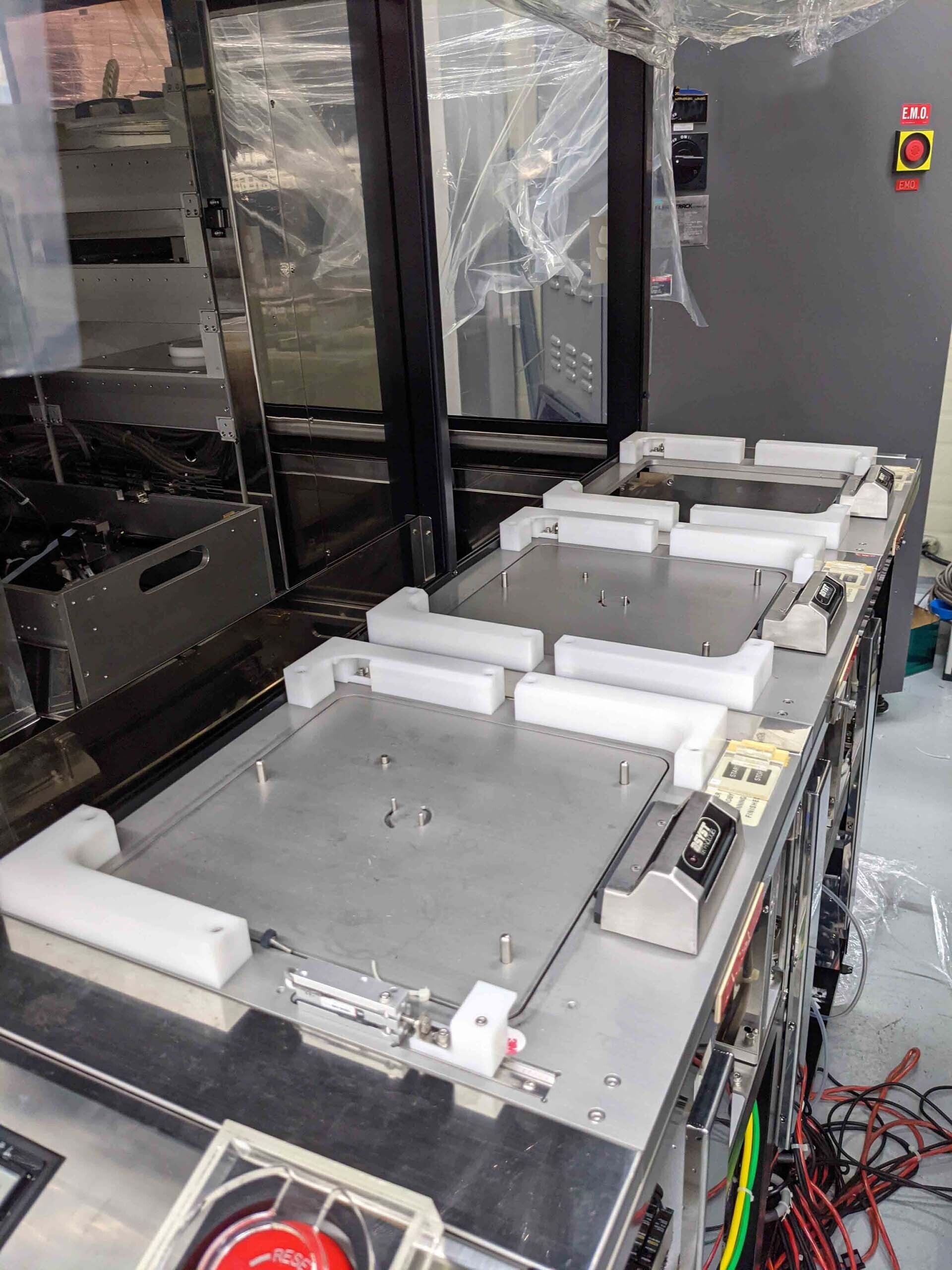

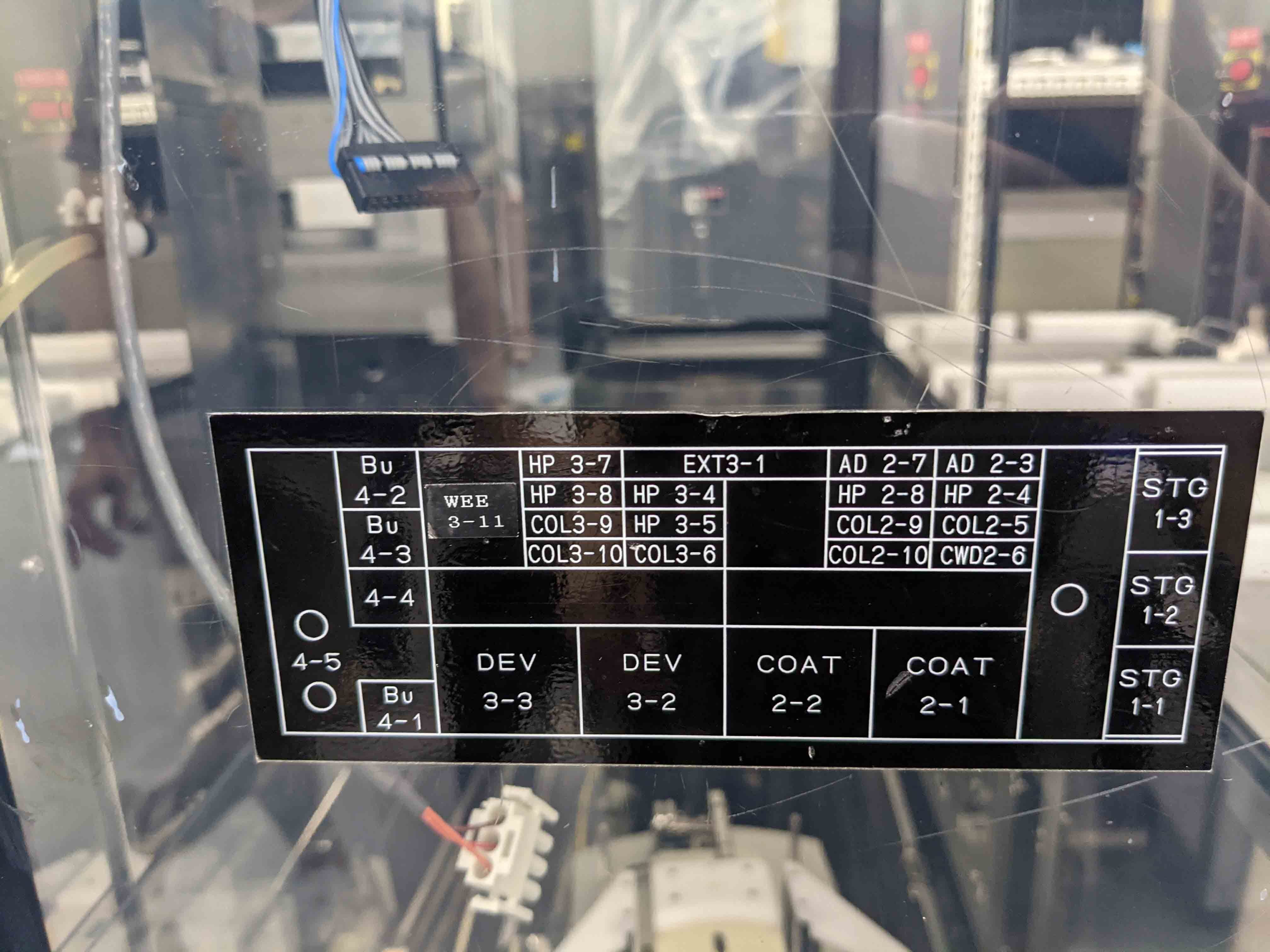

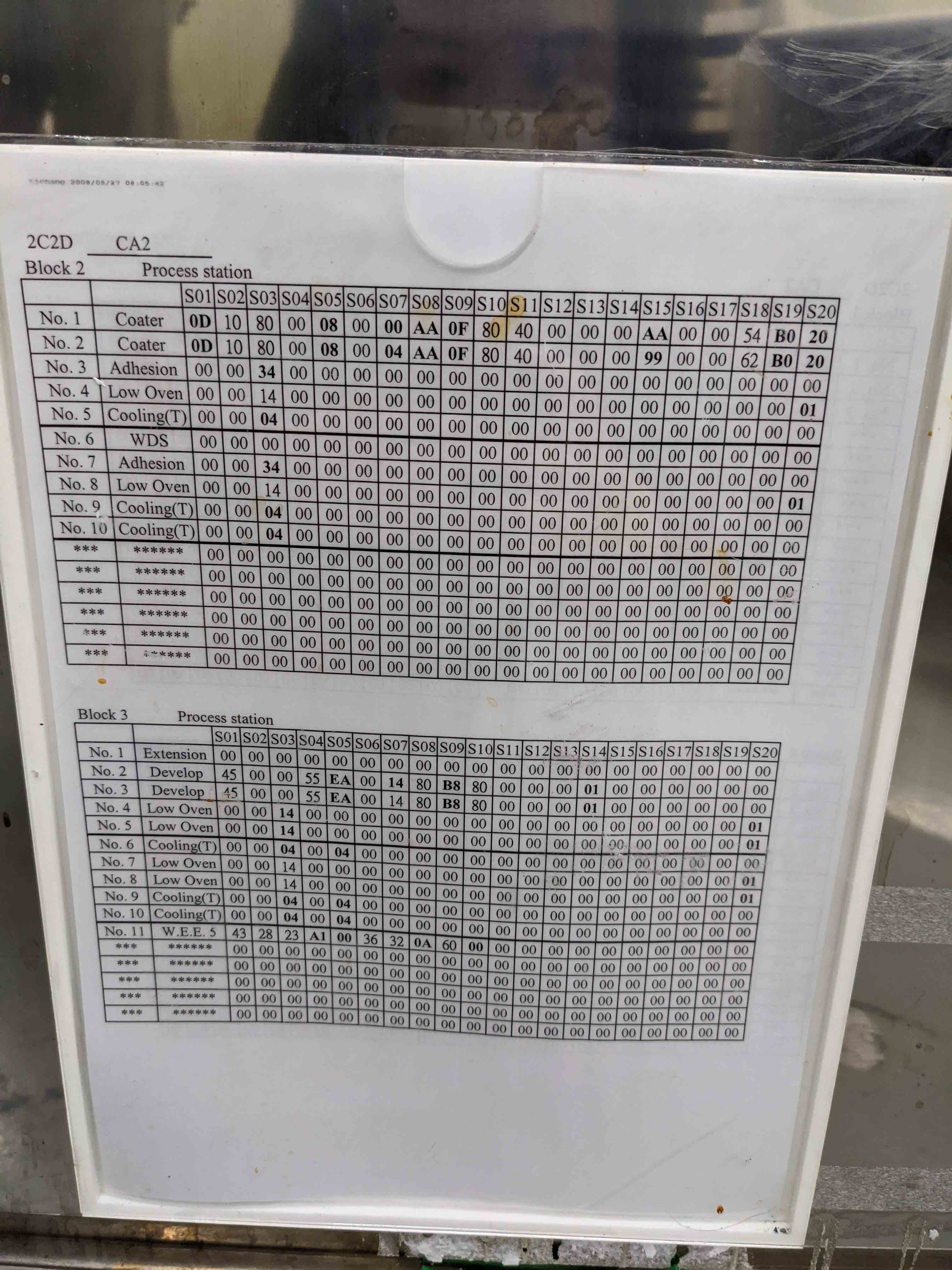

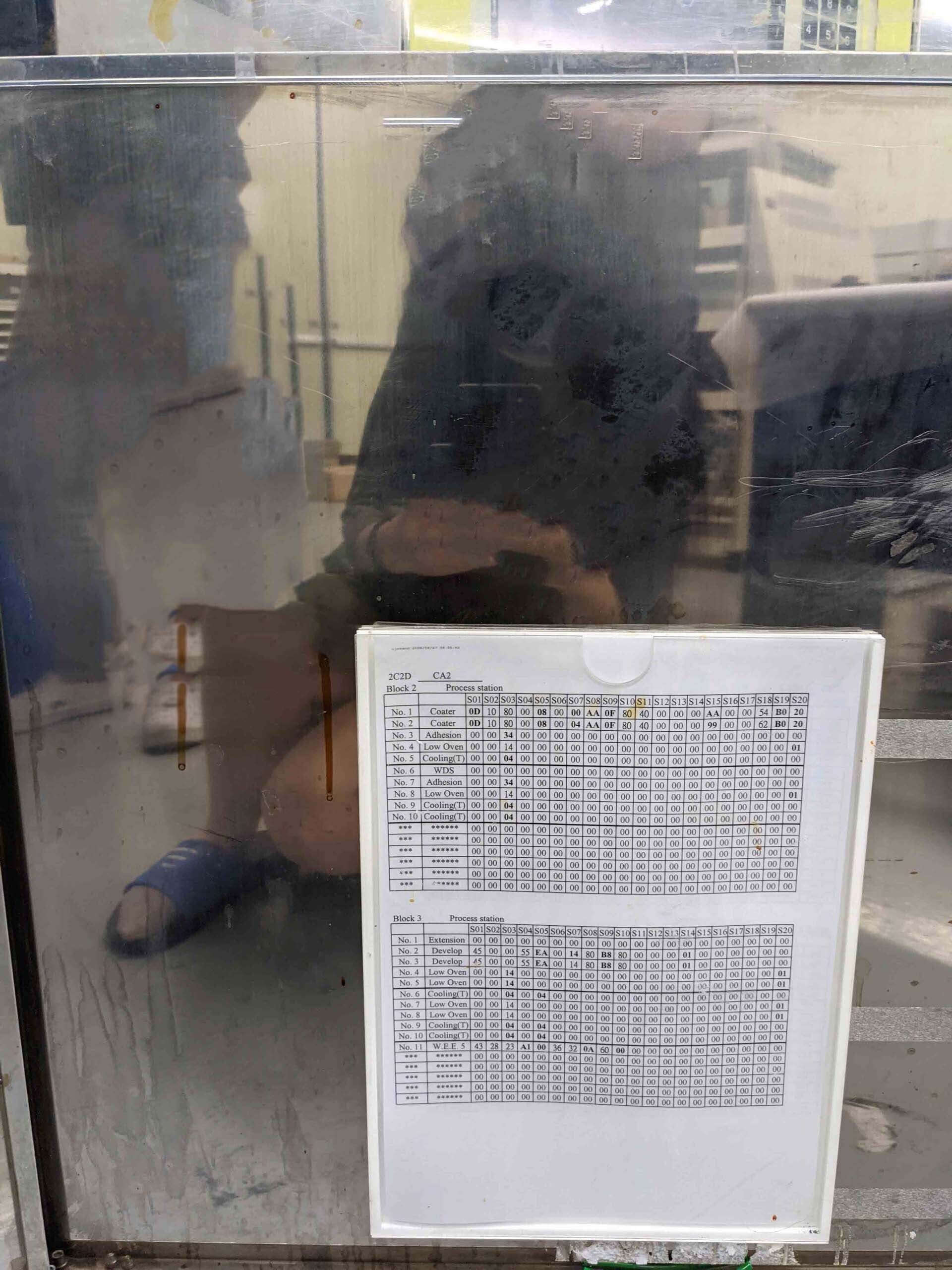

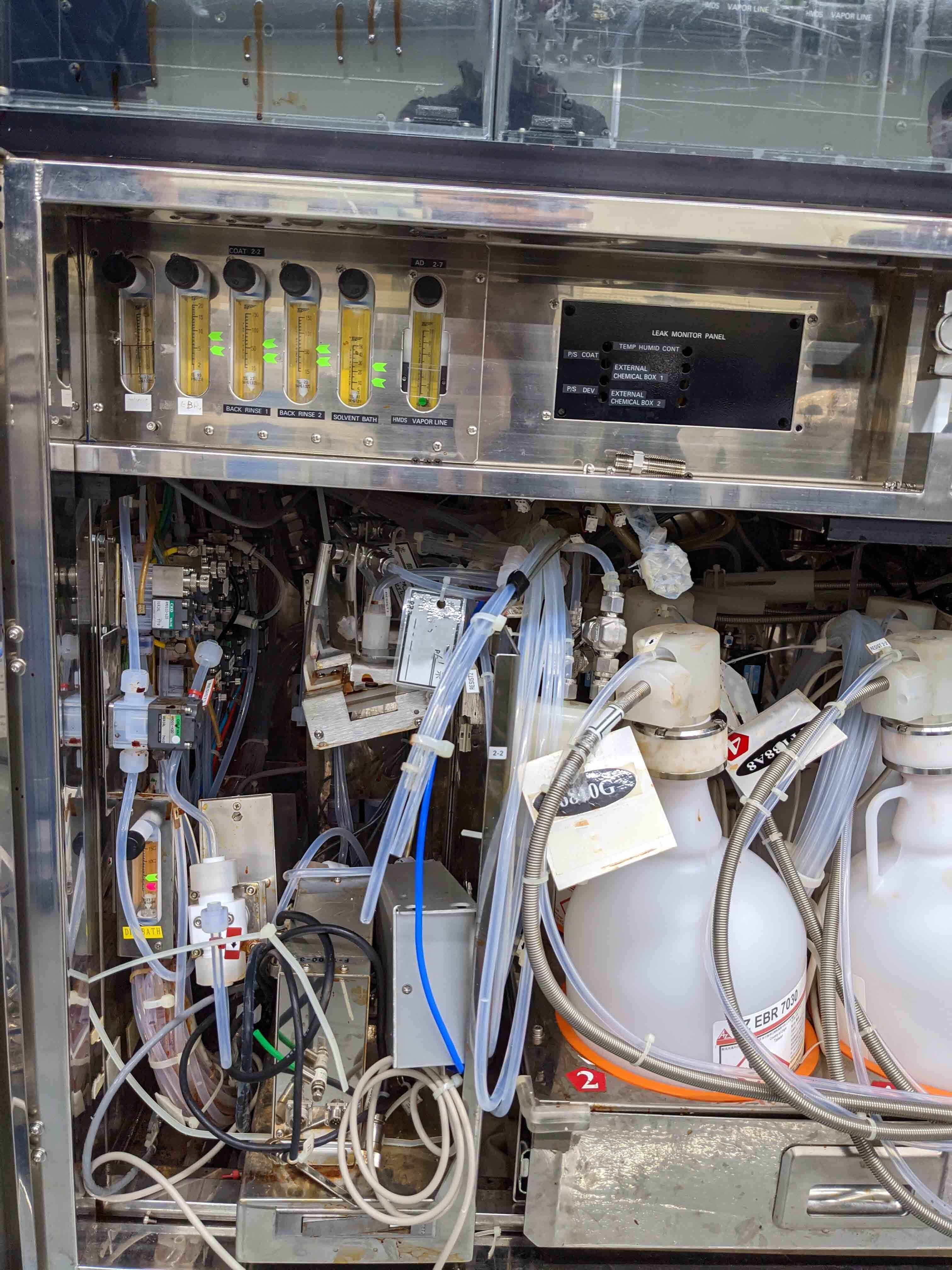

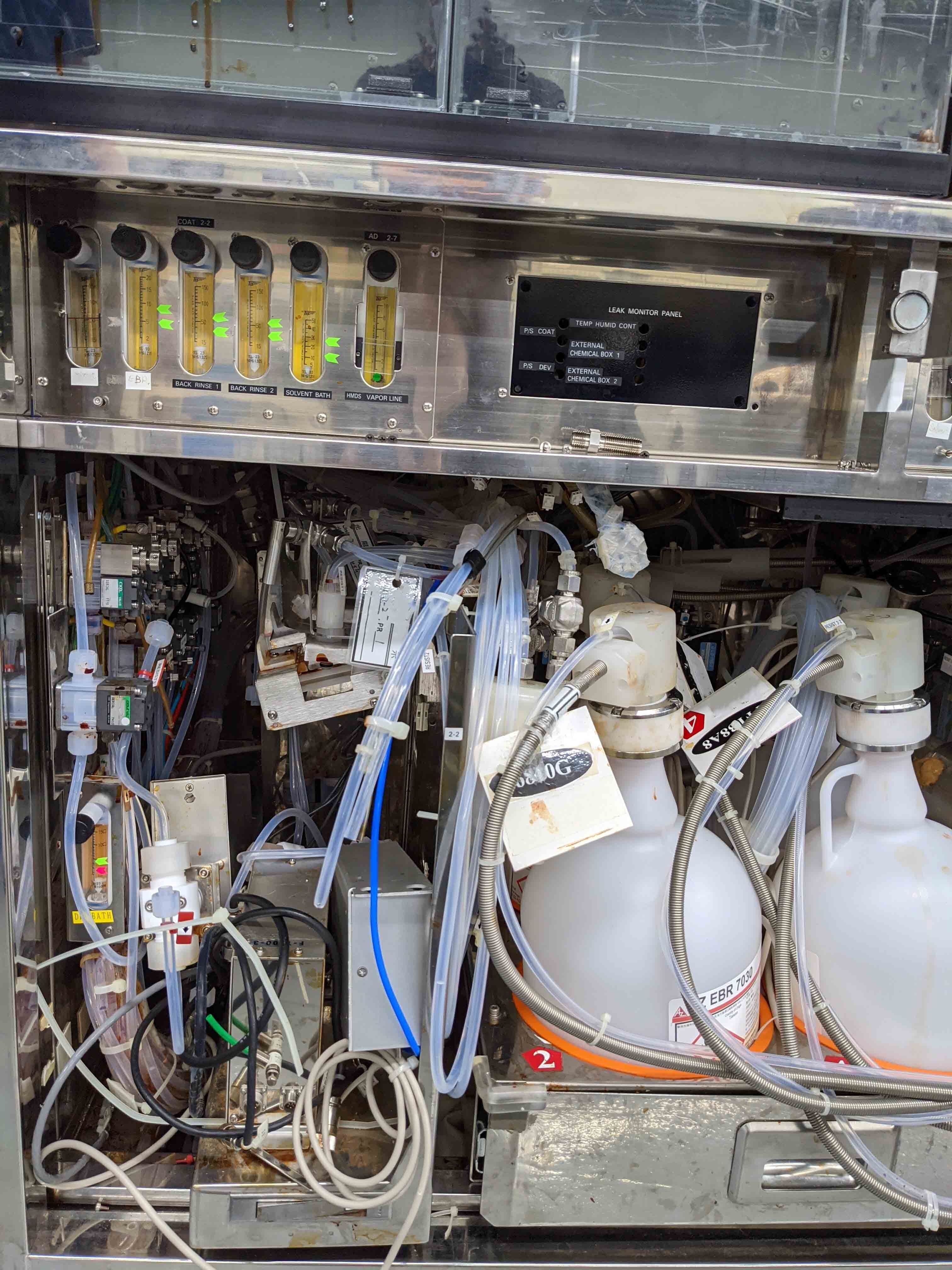

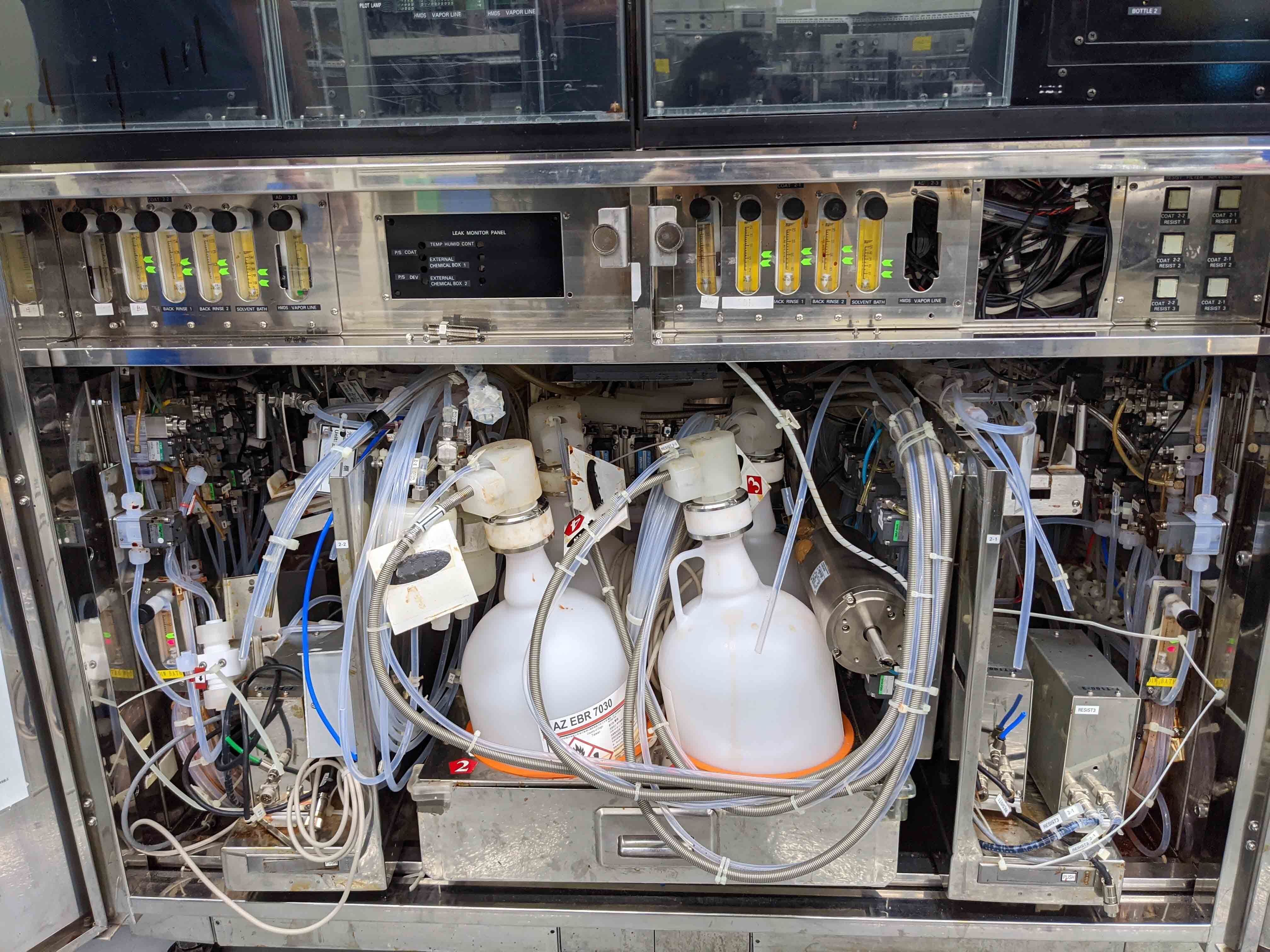

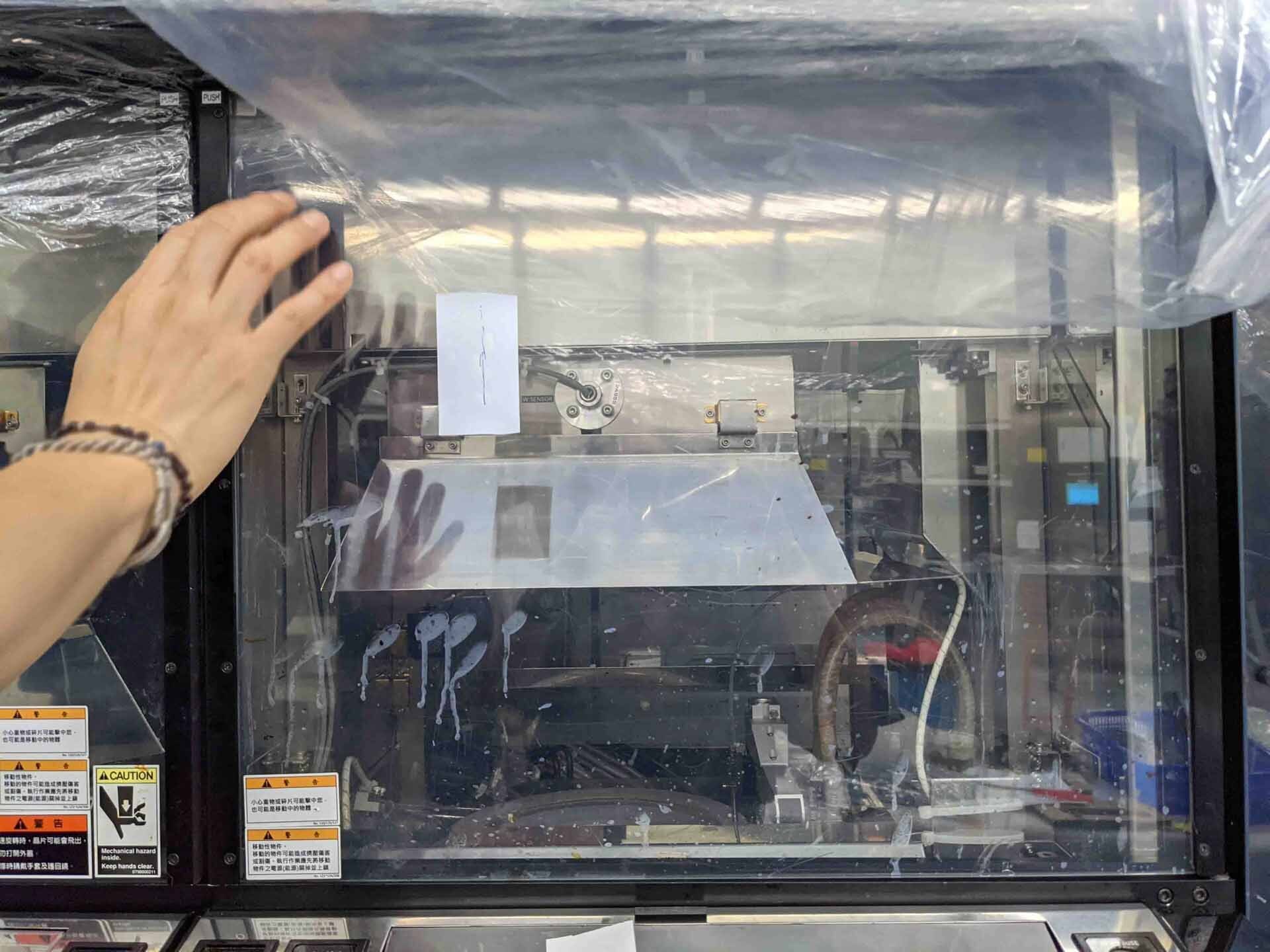

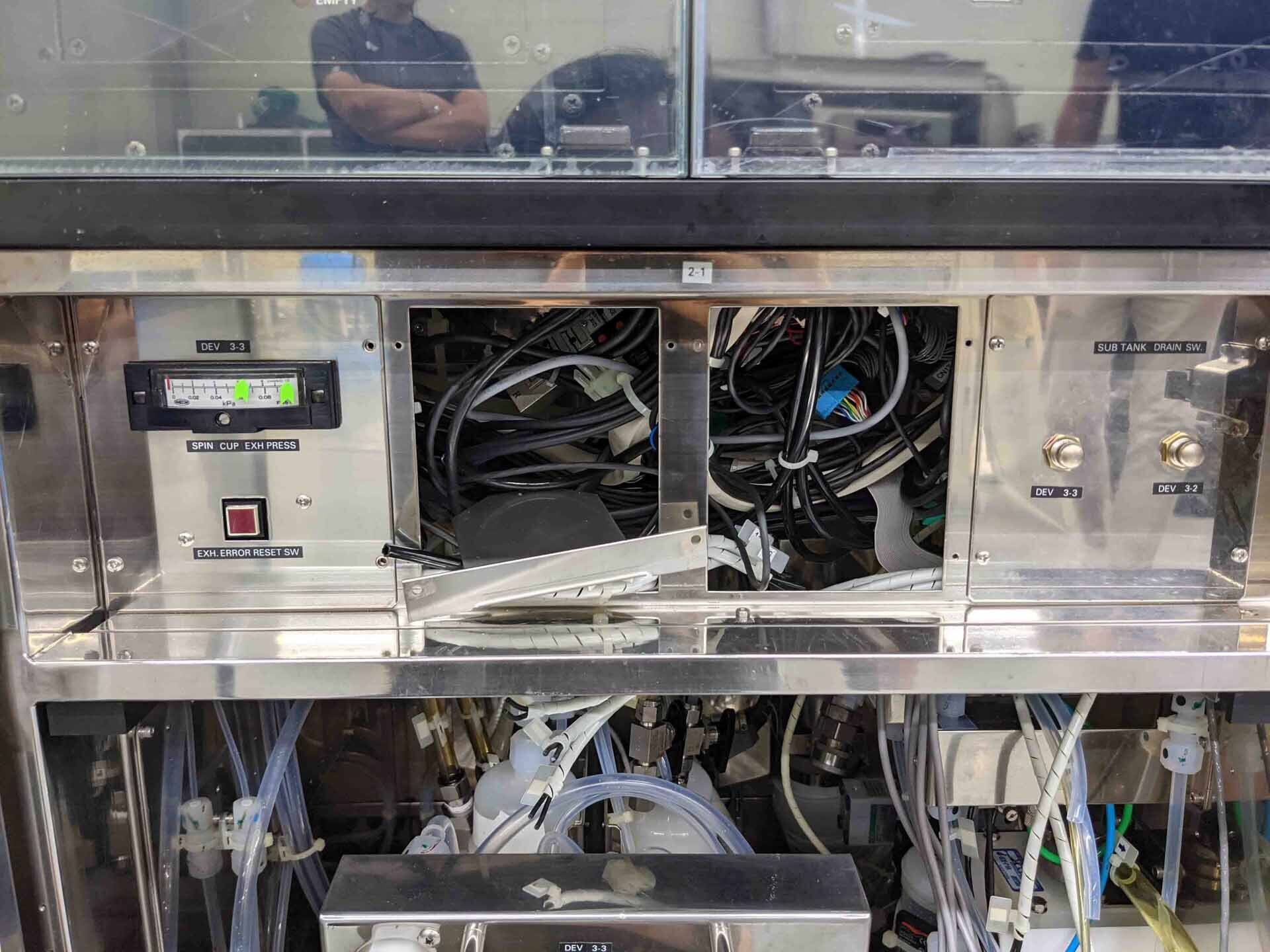

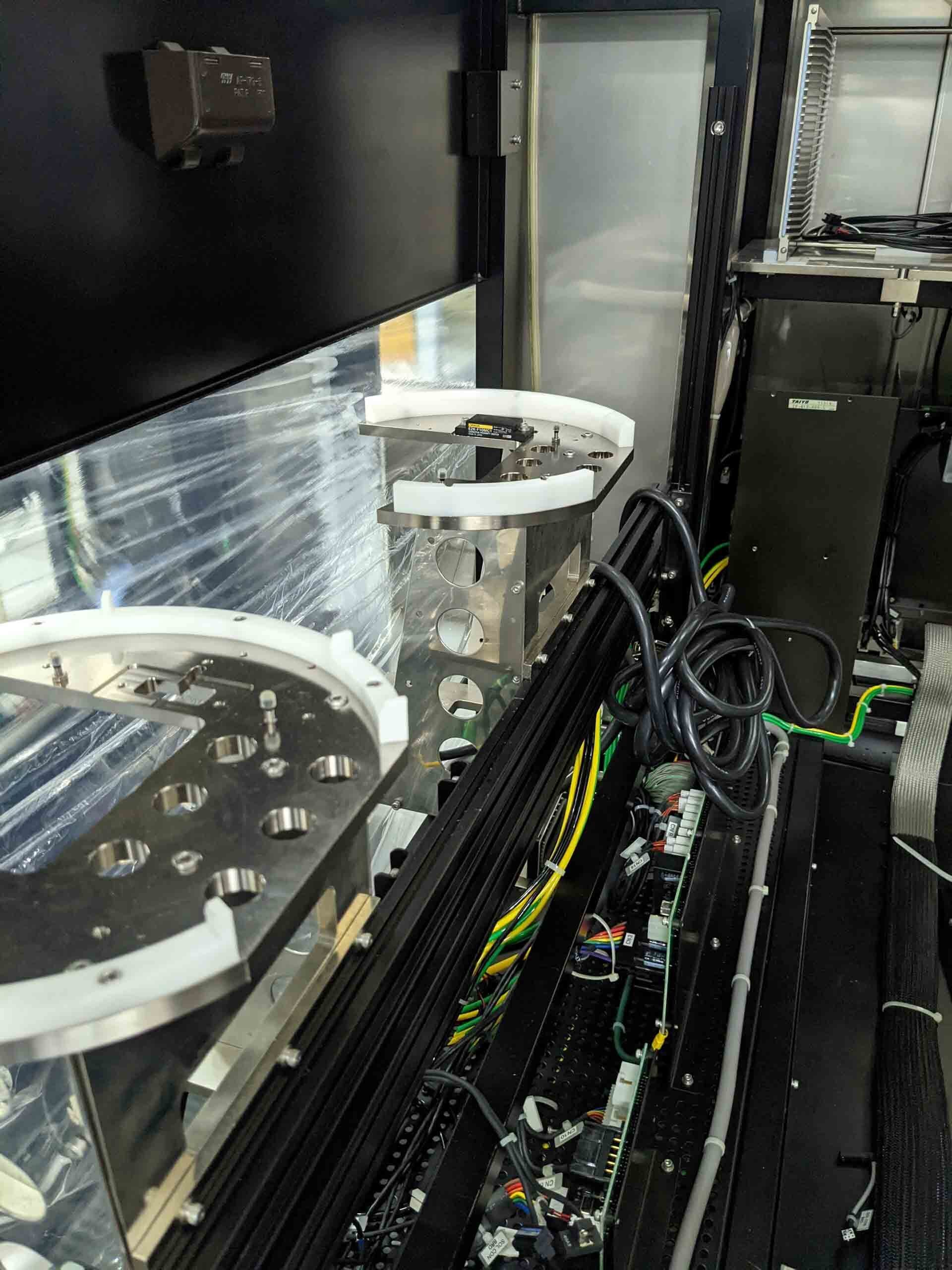

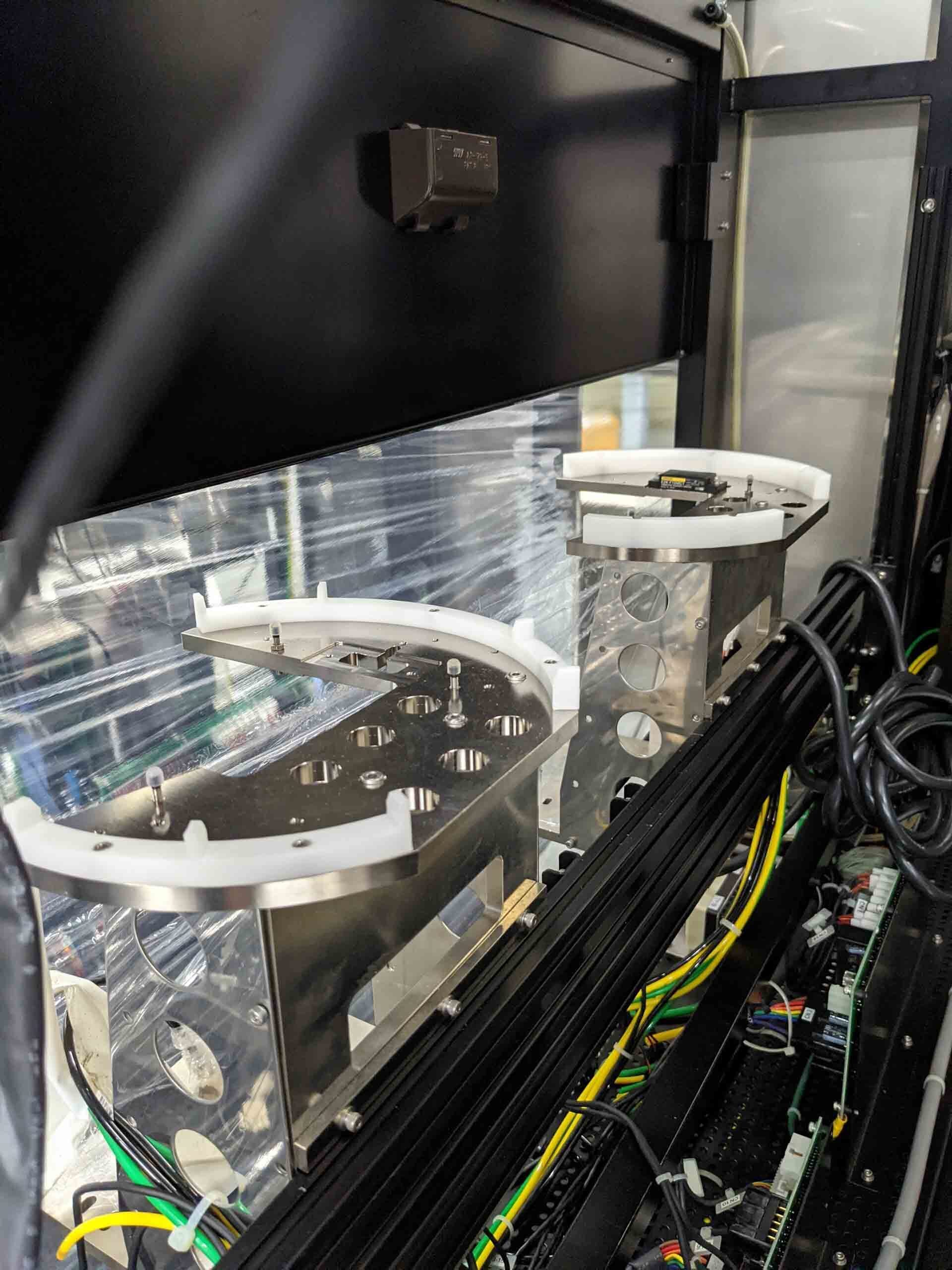

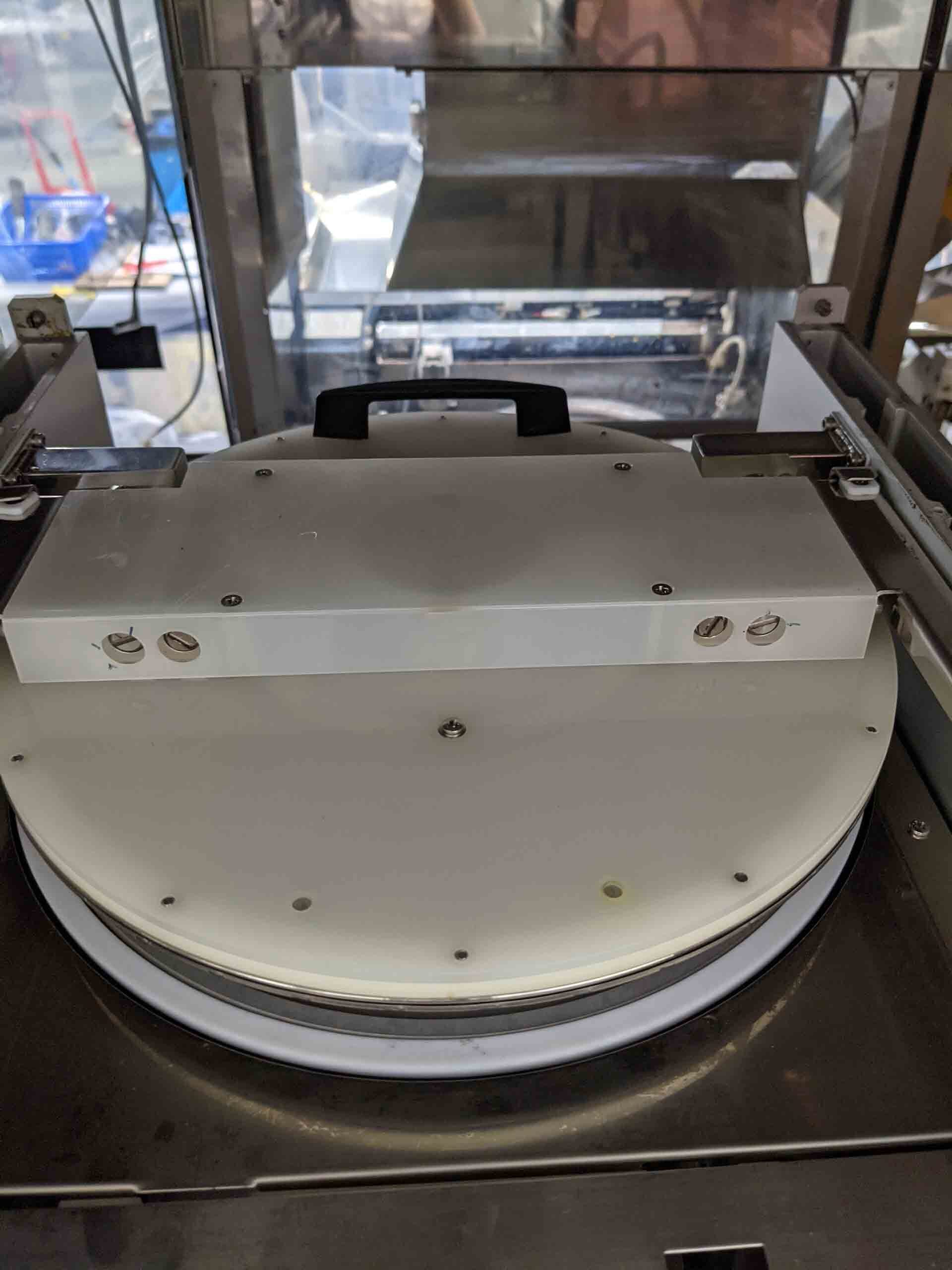

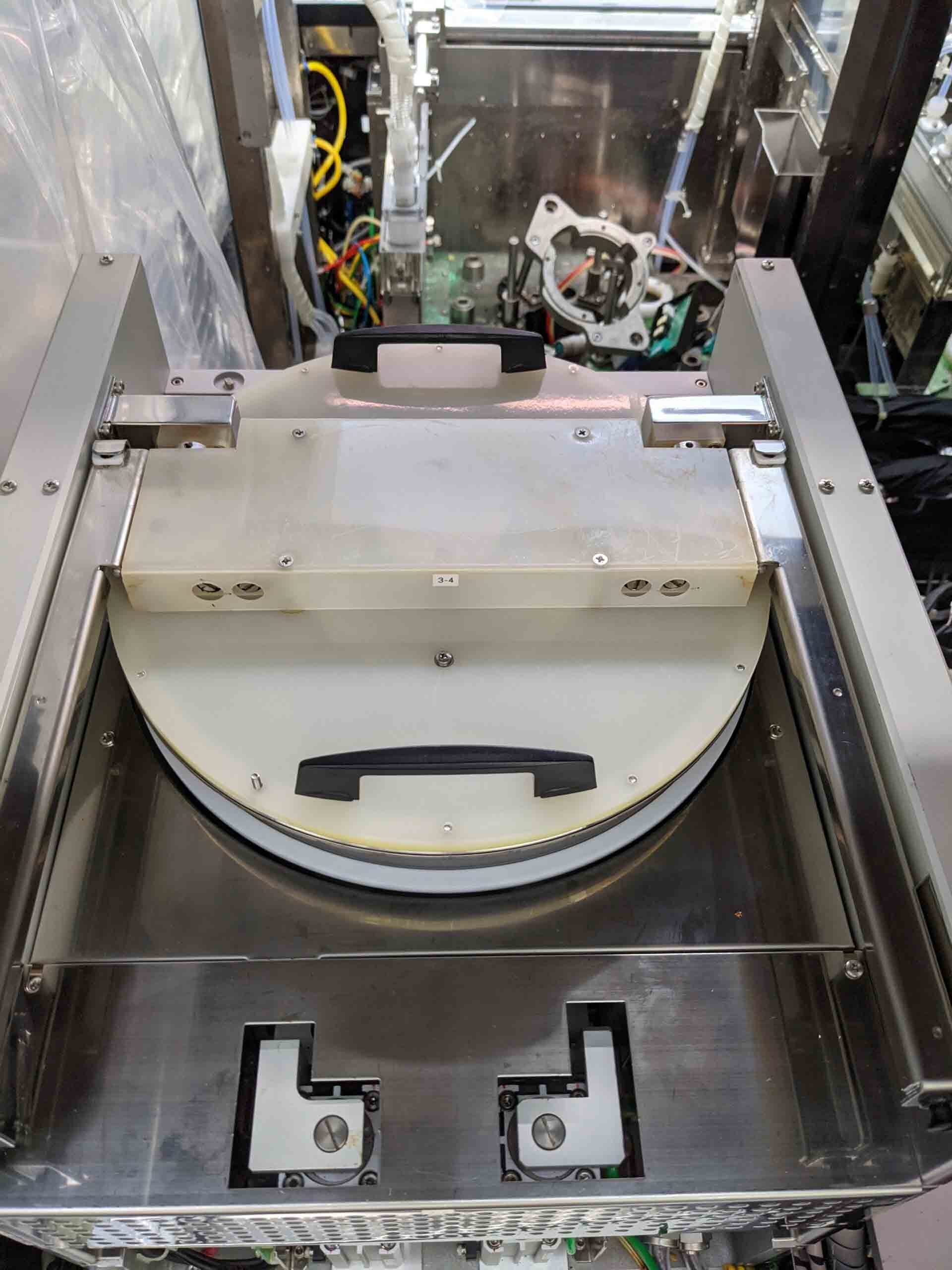

(2) Coater / (2) Developer system, 8"

Dual blocks

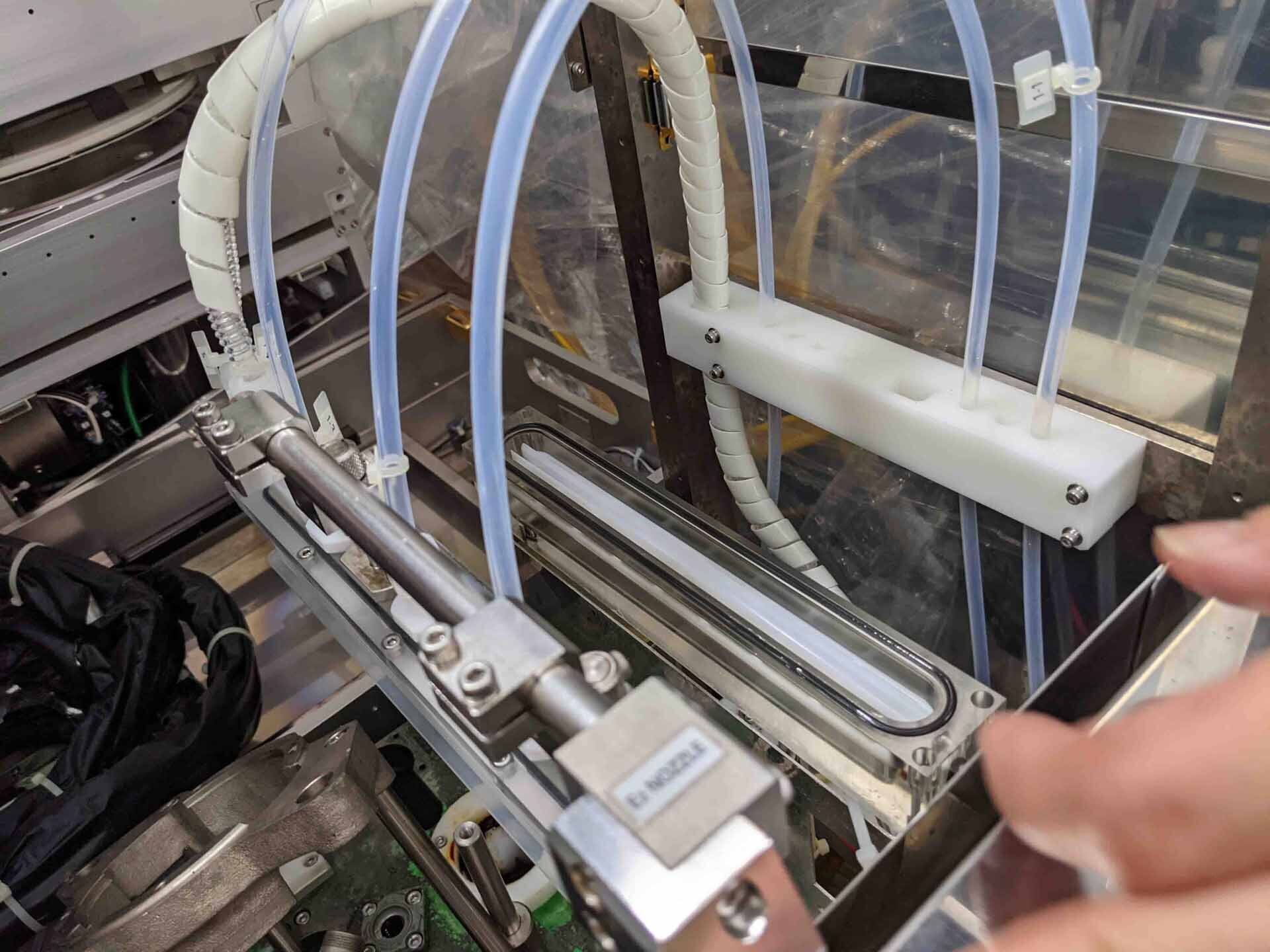

Coater: (3) Nozzles

Developer: E2 Nozzle

Wafer flow: Right to left (CSB Unit right side and interface station left side)

Tank auto switch off / Exchange missing

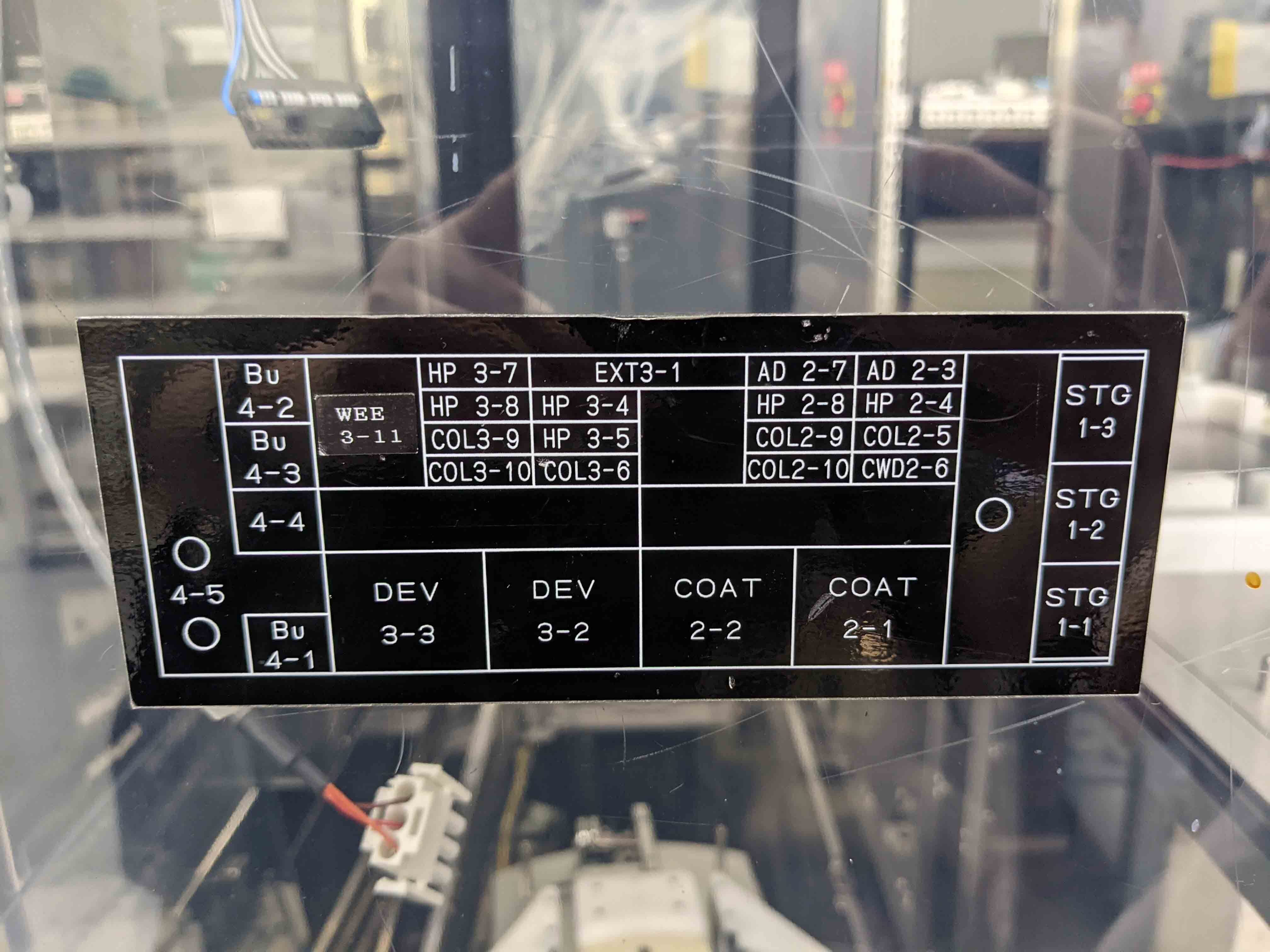

Block 1:

FC-9821Ke Controller

Stage / Indexer: SMIF / Cassette station

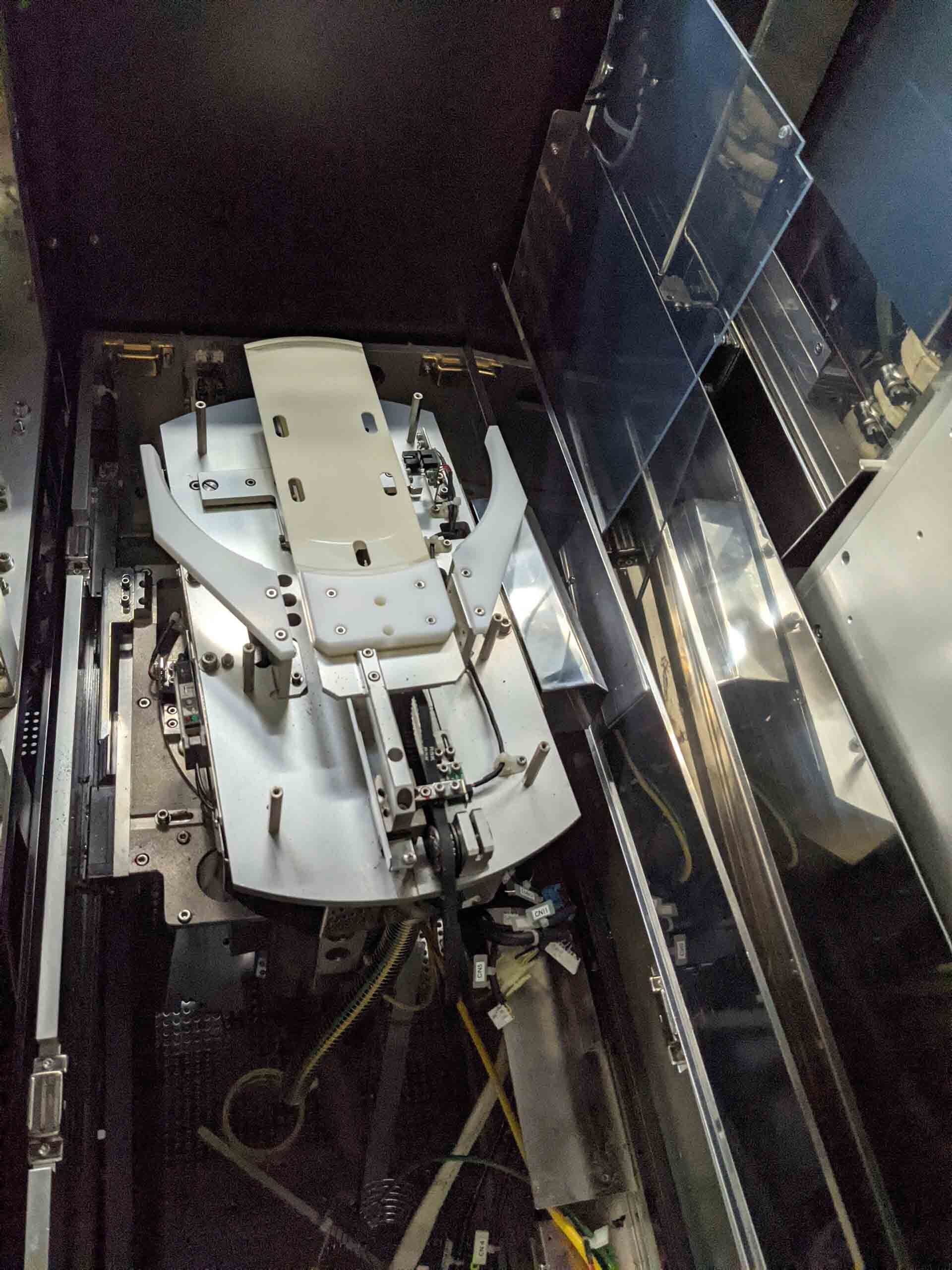

Cassette Station Arm (CSA)

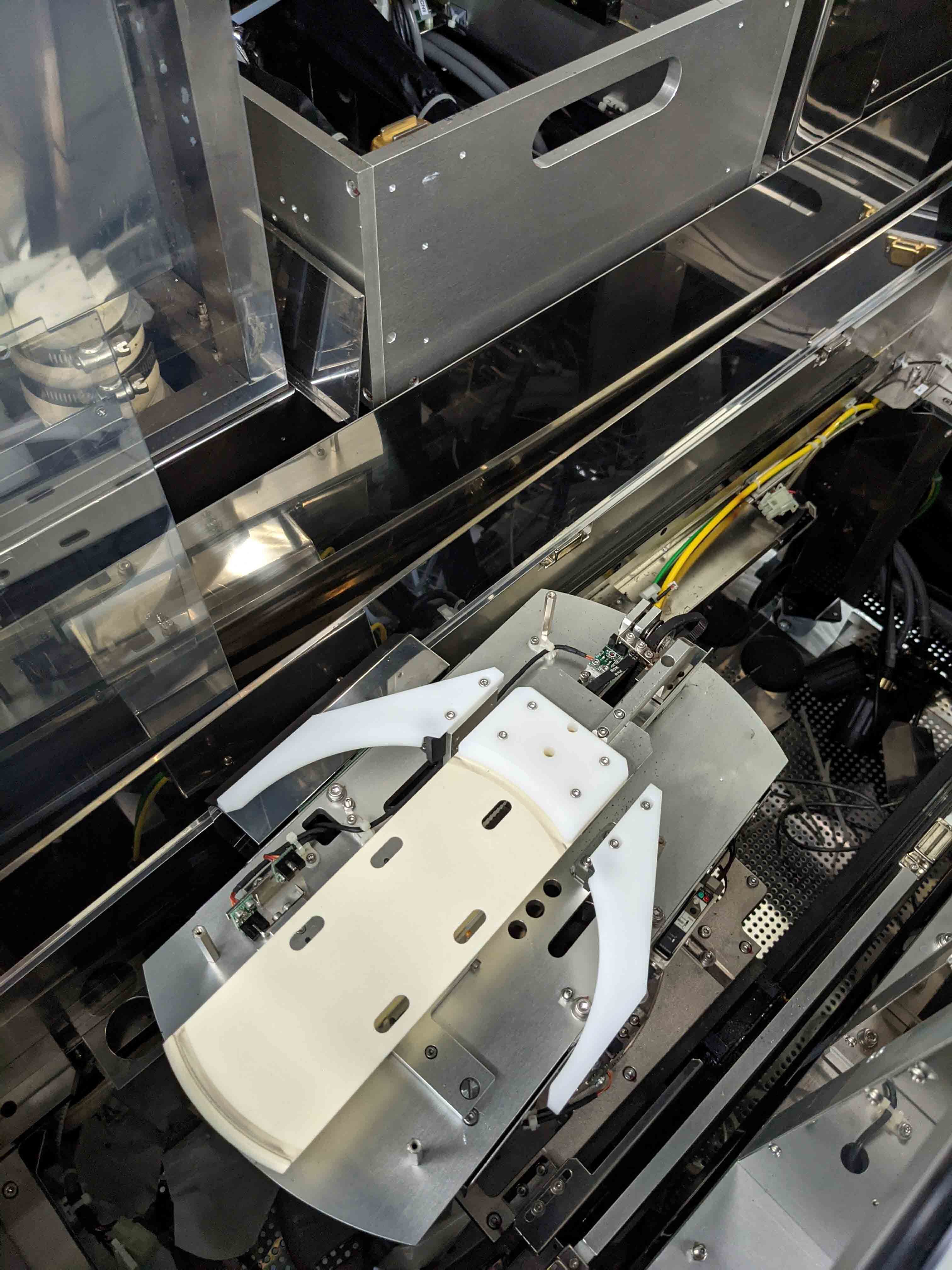

Block 2:

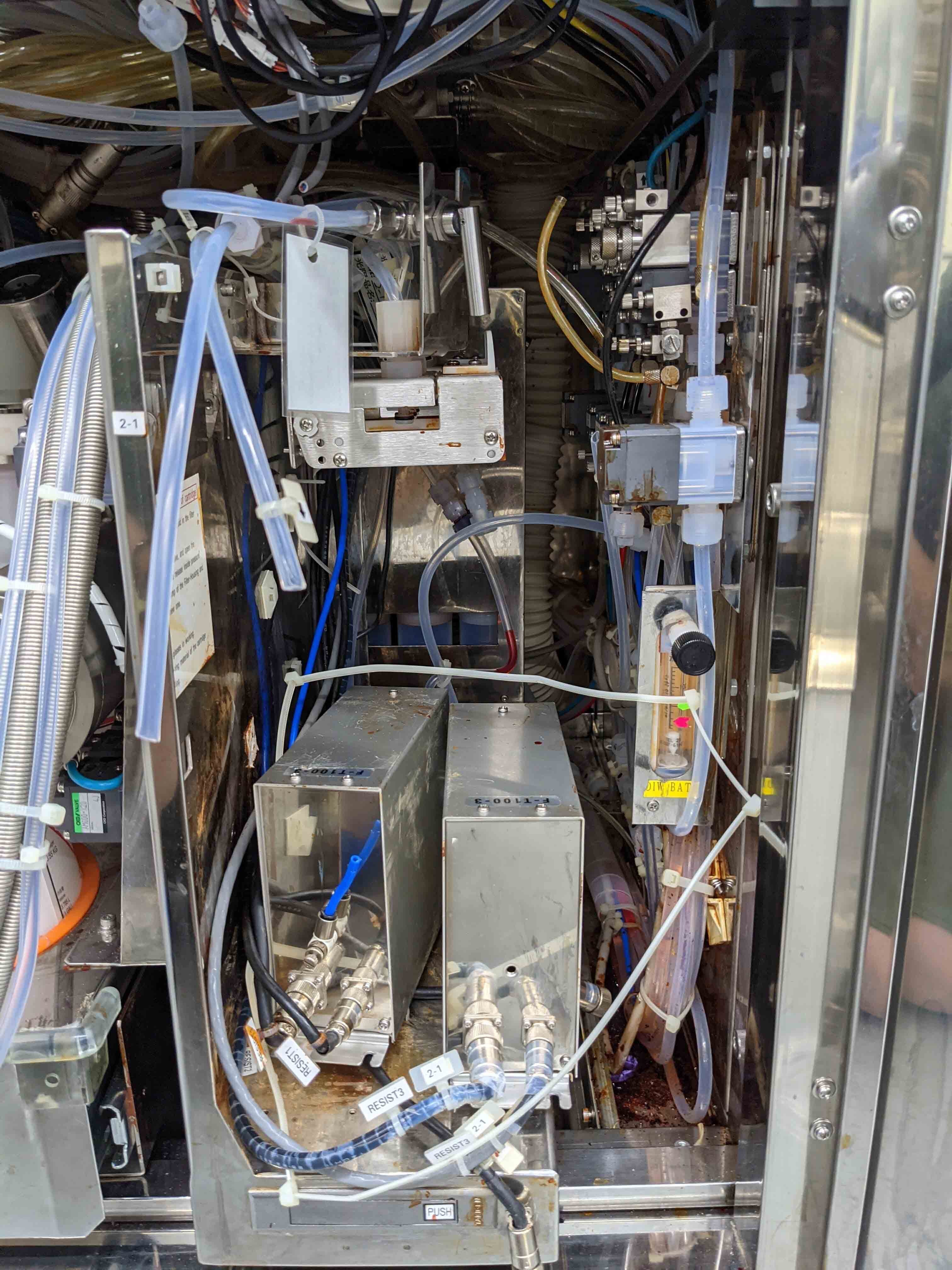

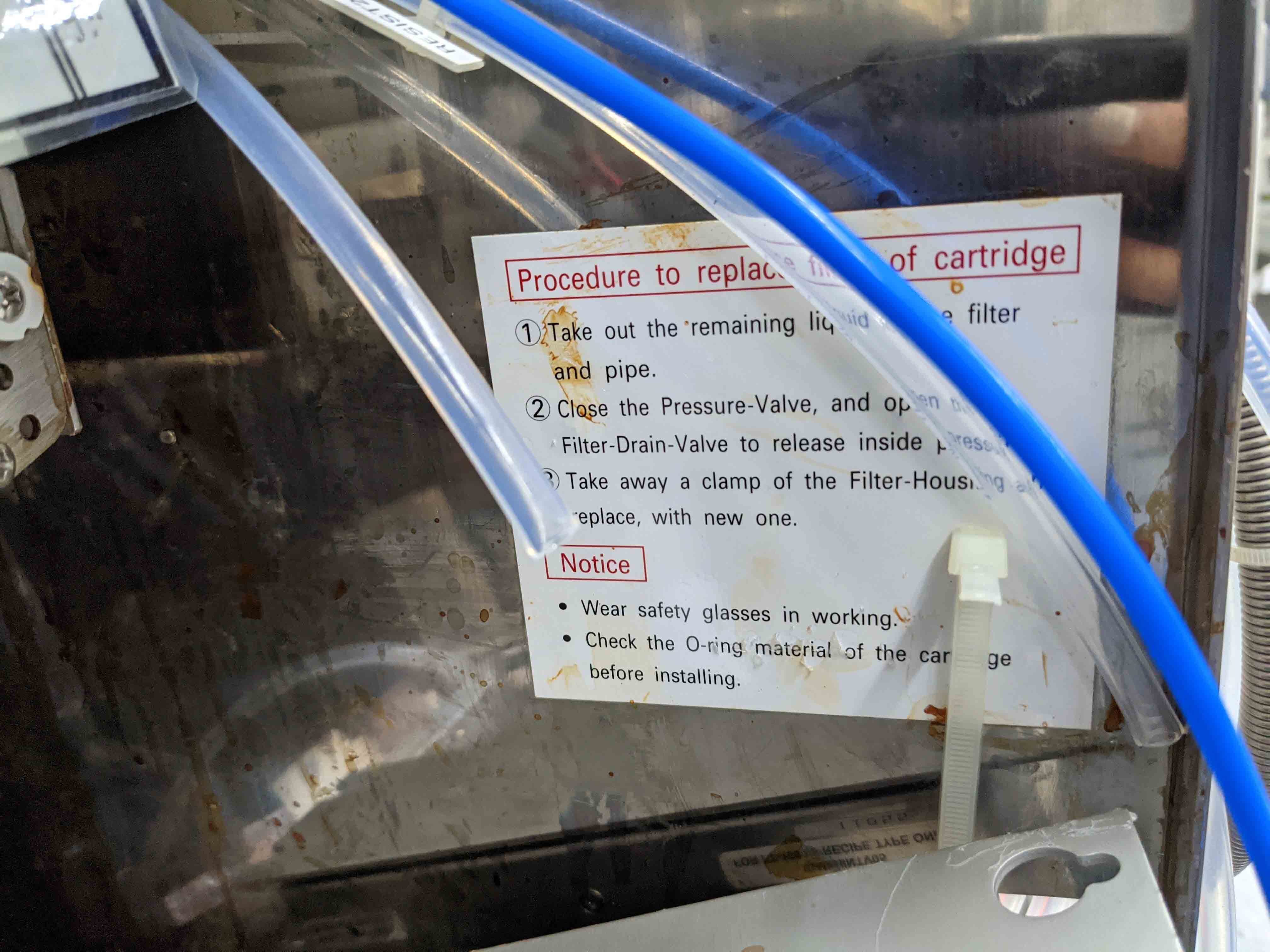

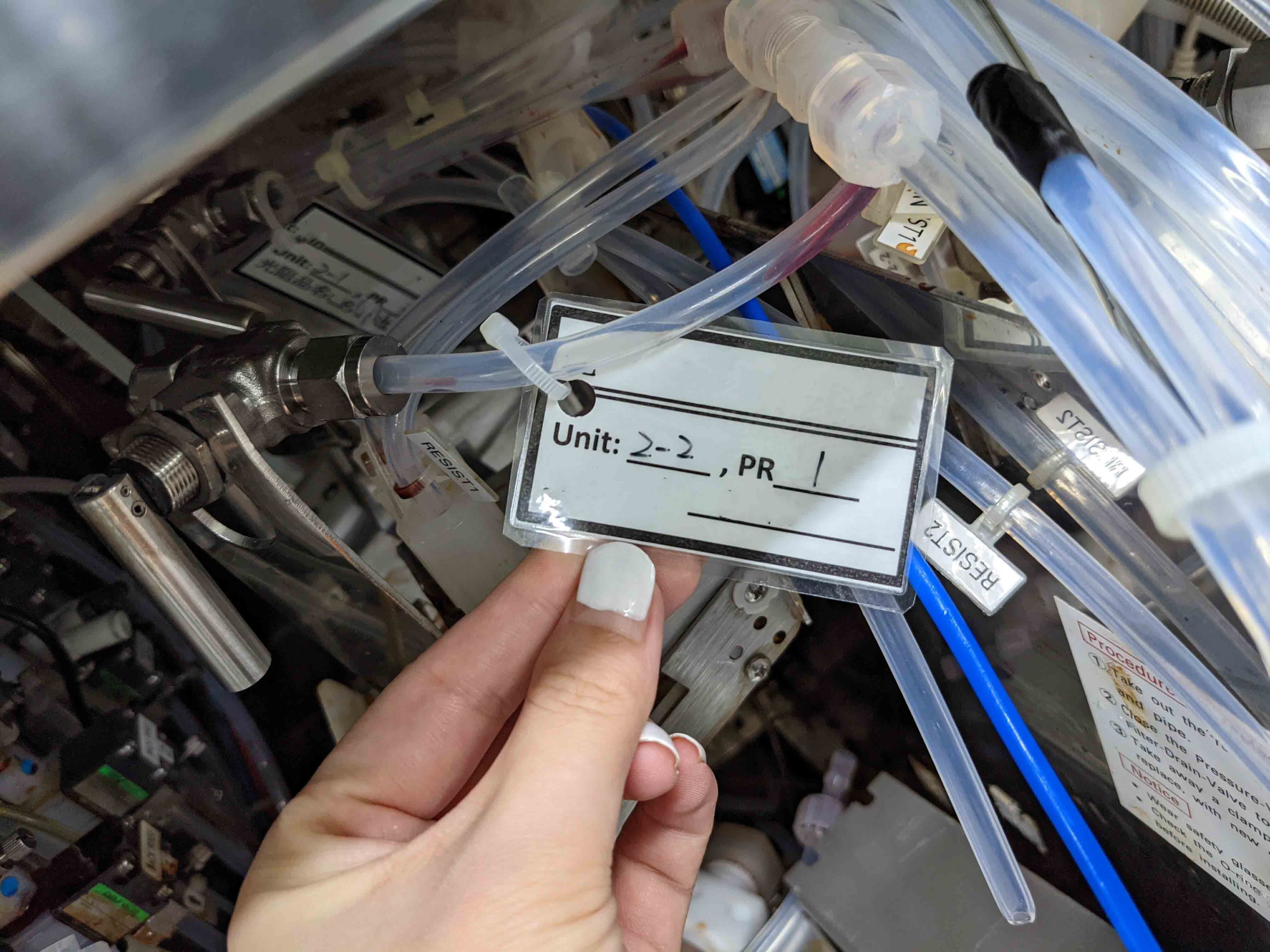

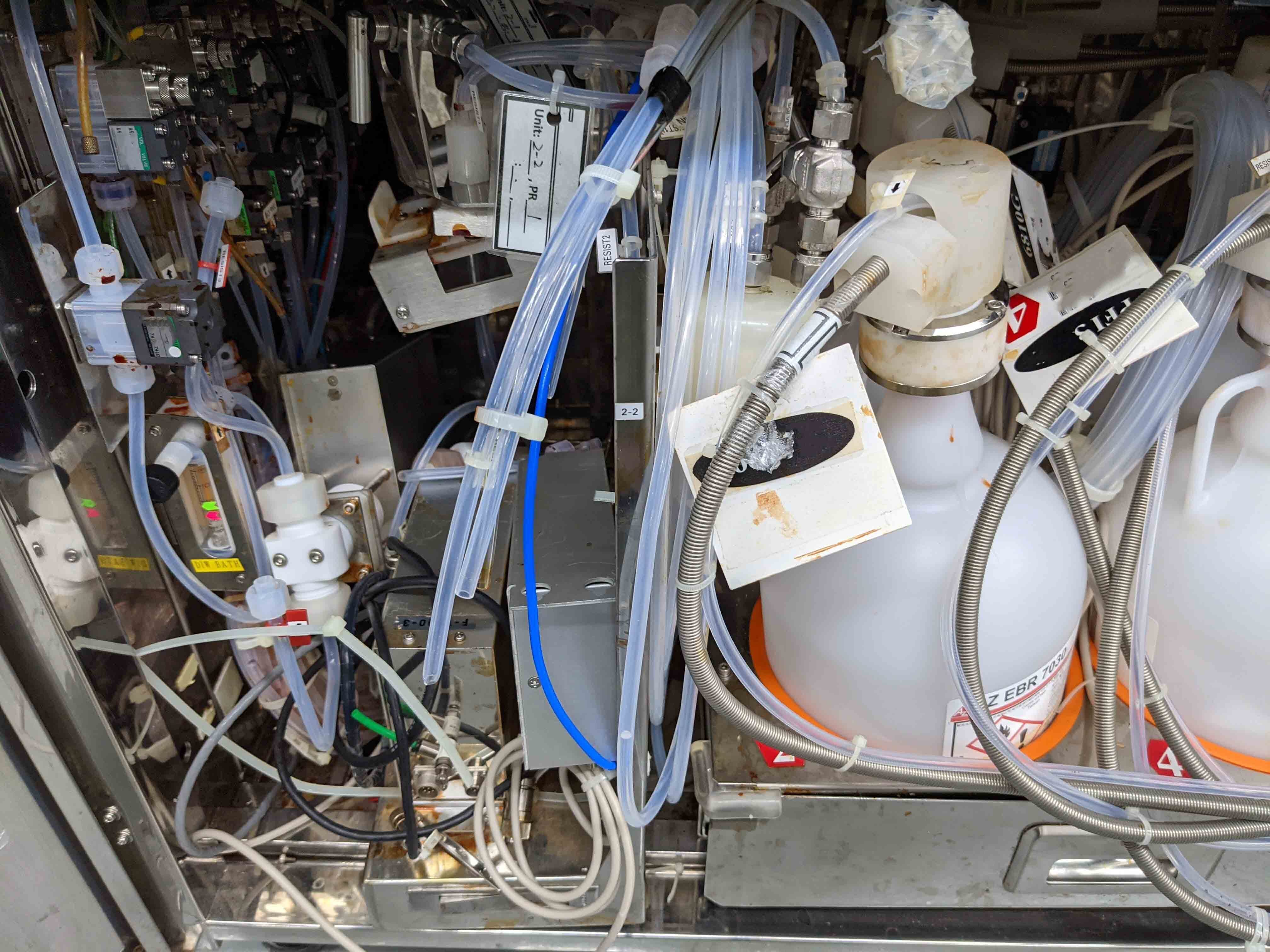

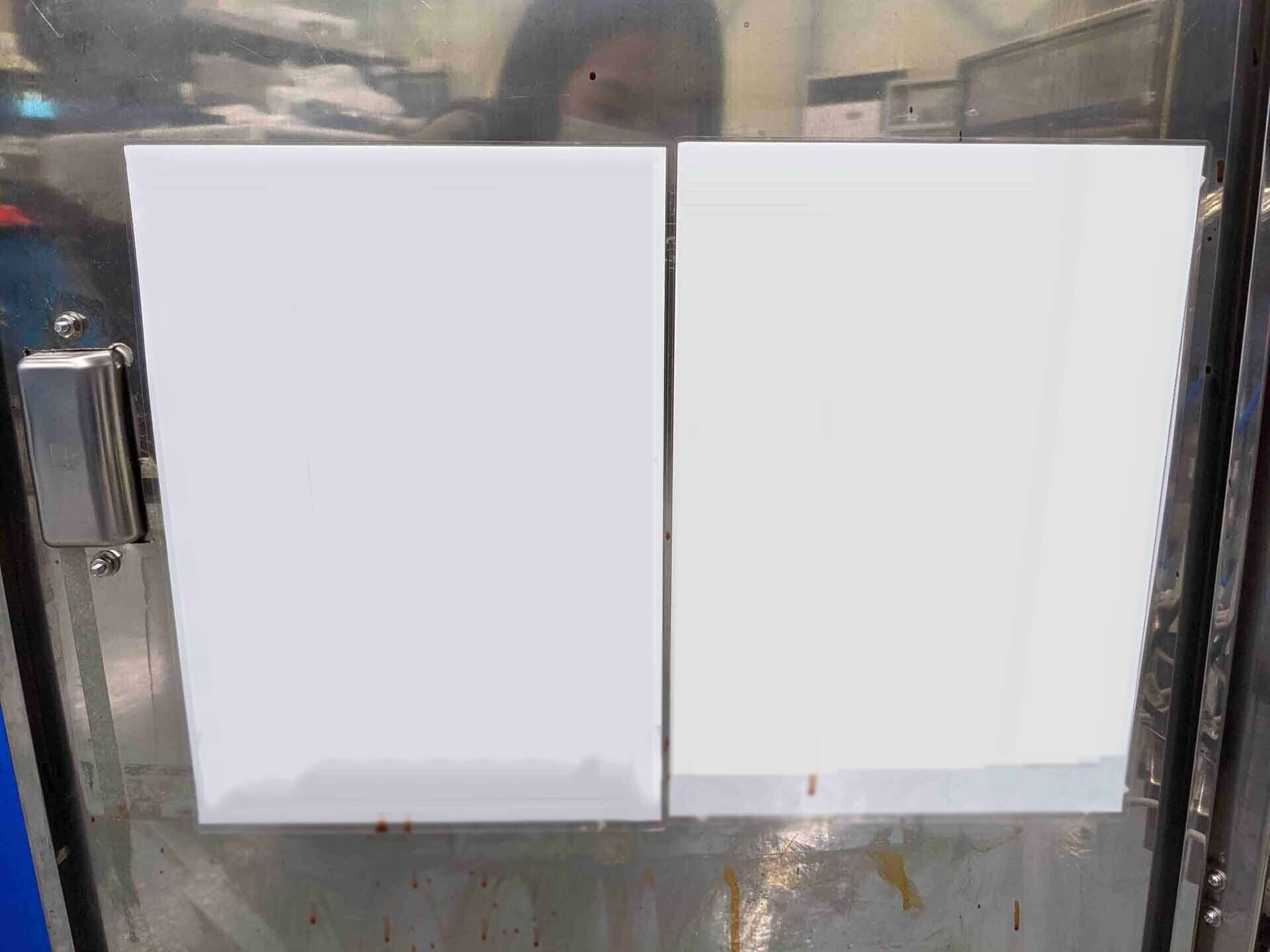

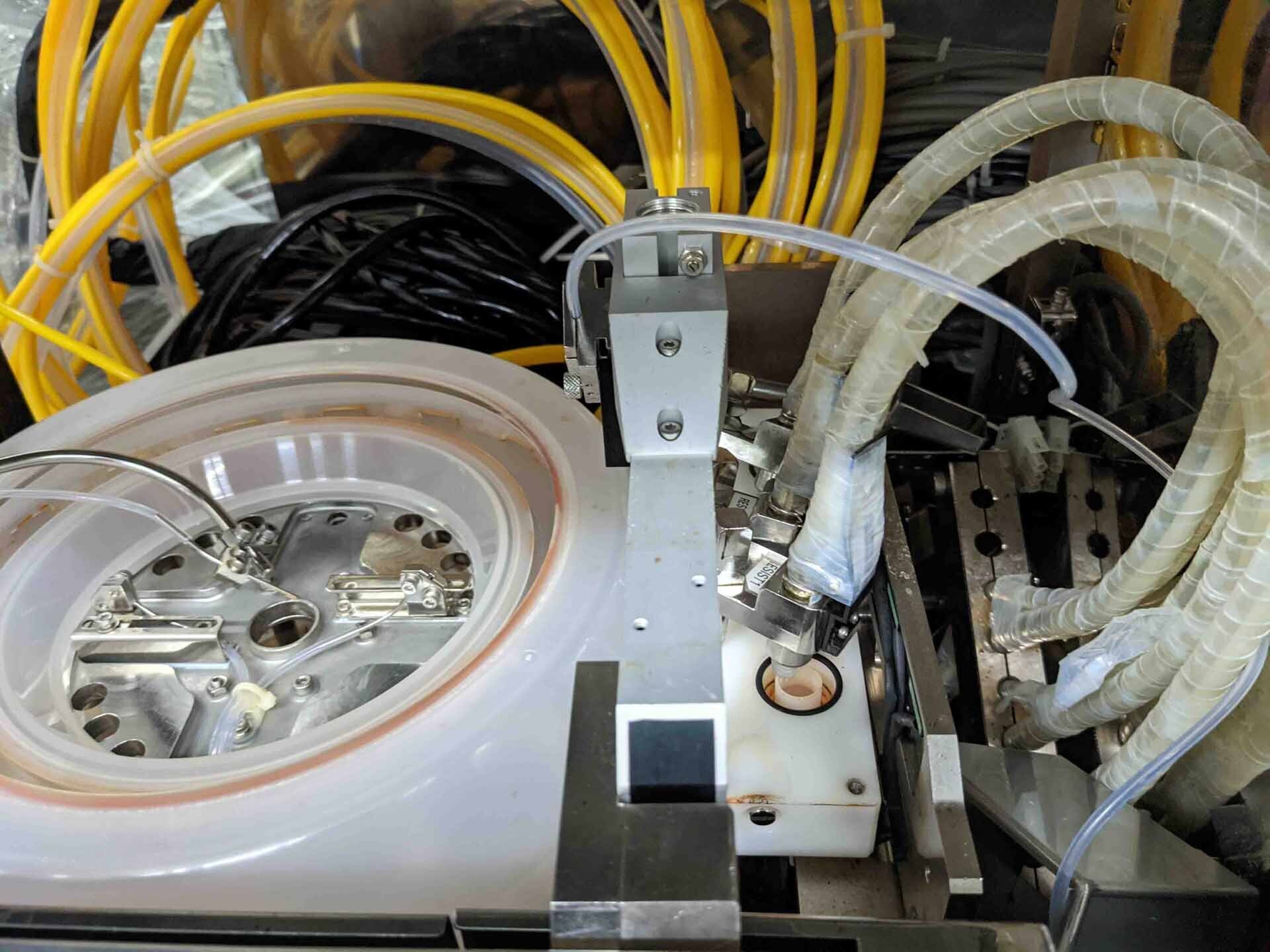

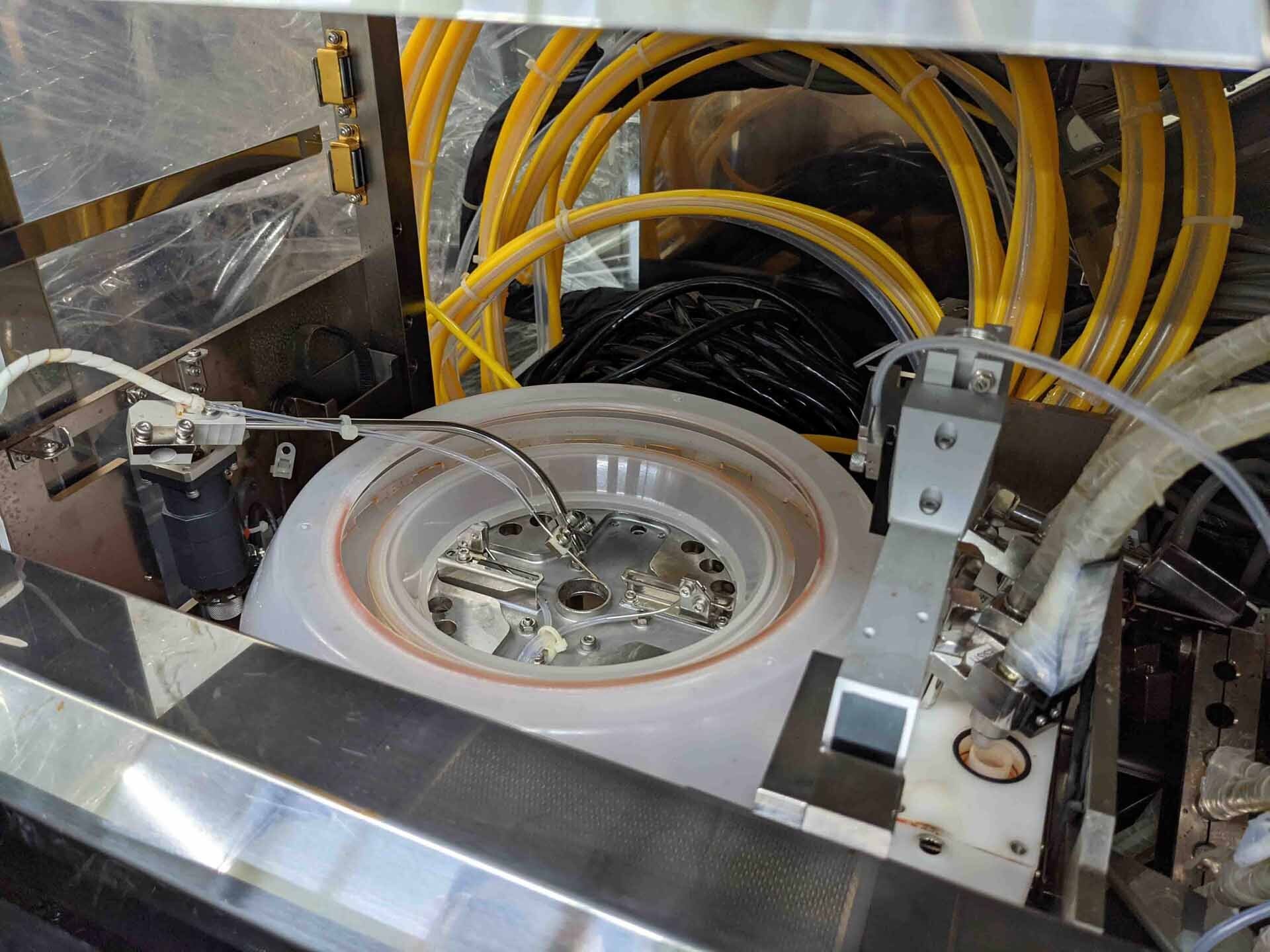

Normal photo resist coater 2-1, 2-2:

(2) Photoresist dispense nozzles per coat unit

(2) Photoresist dispense nozzles and 2-RRC Resist pump per coater

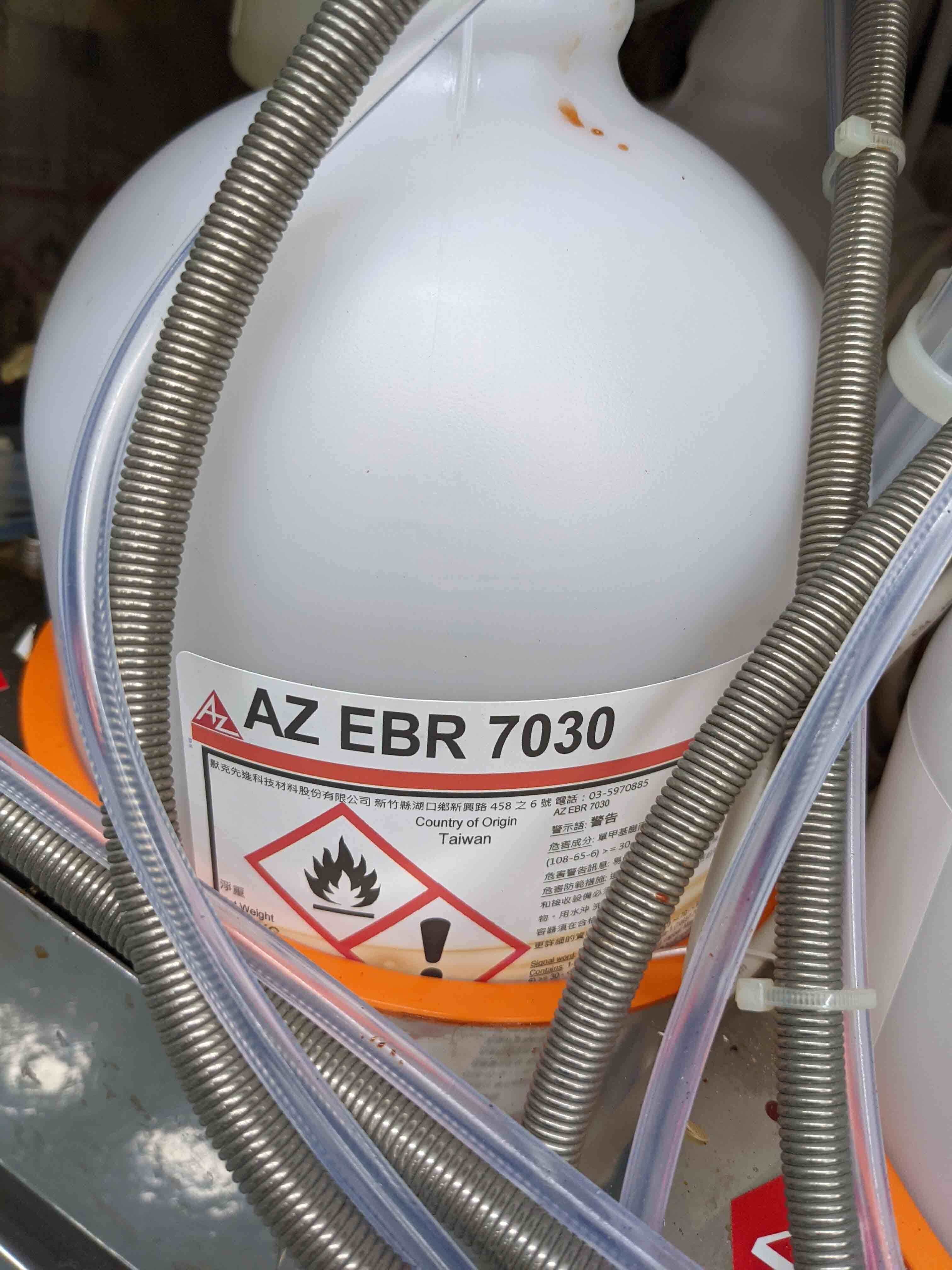

Side rinse nozzle (Programmable side rinse EBR) for normal coater

Dual back rinse nozzle

Photoresist temperature control

Motor flange temperature control

Photoresist drain type: Direct gravity

Photoresist bottle: 2-Space

Photoresist auto exchange

Auto dummy dispense system

Cup type: PP Upper cup and inner cup

Auto damper: Cylinder

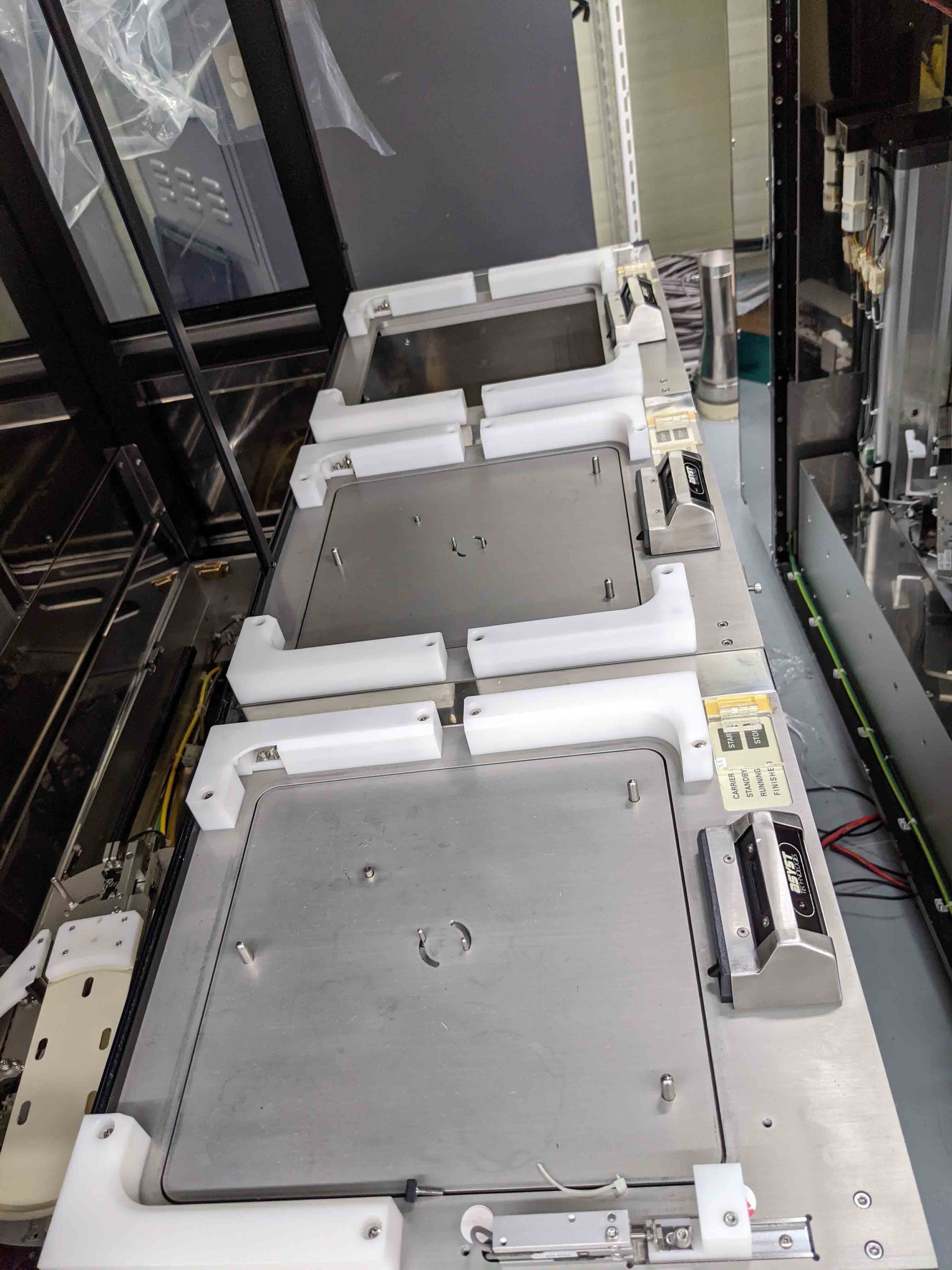

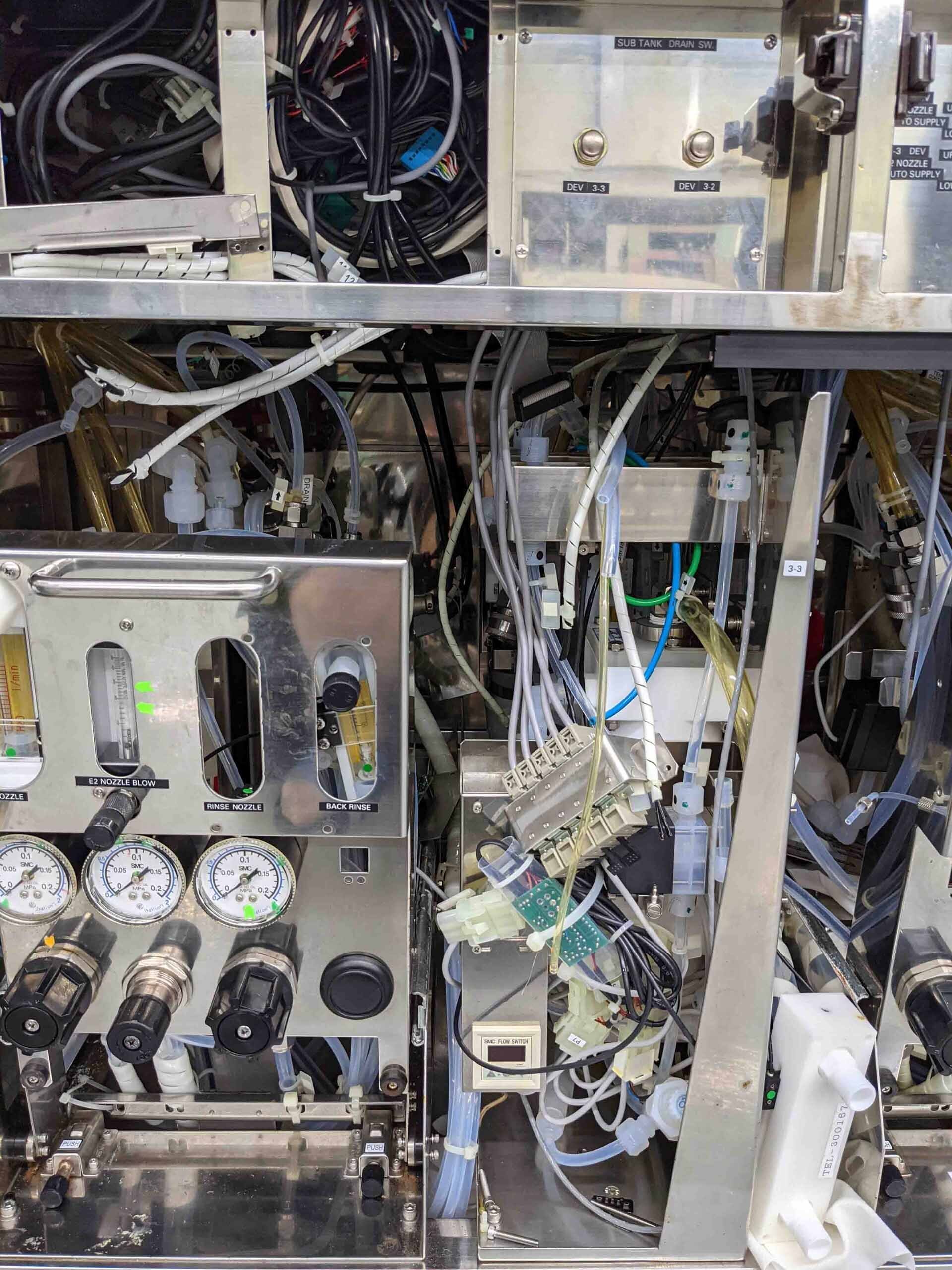

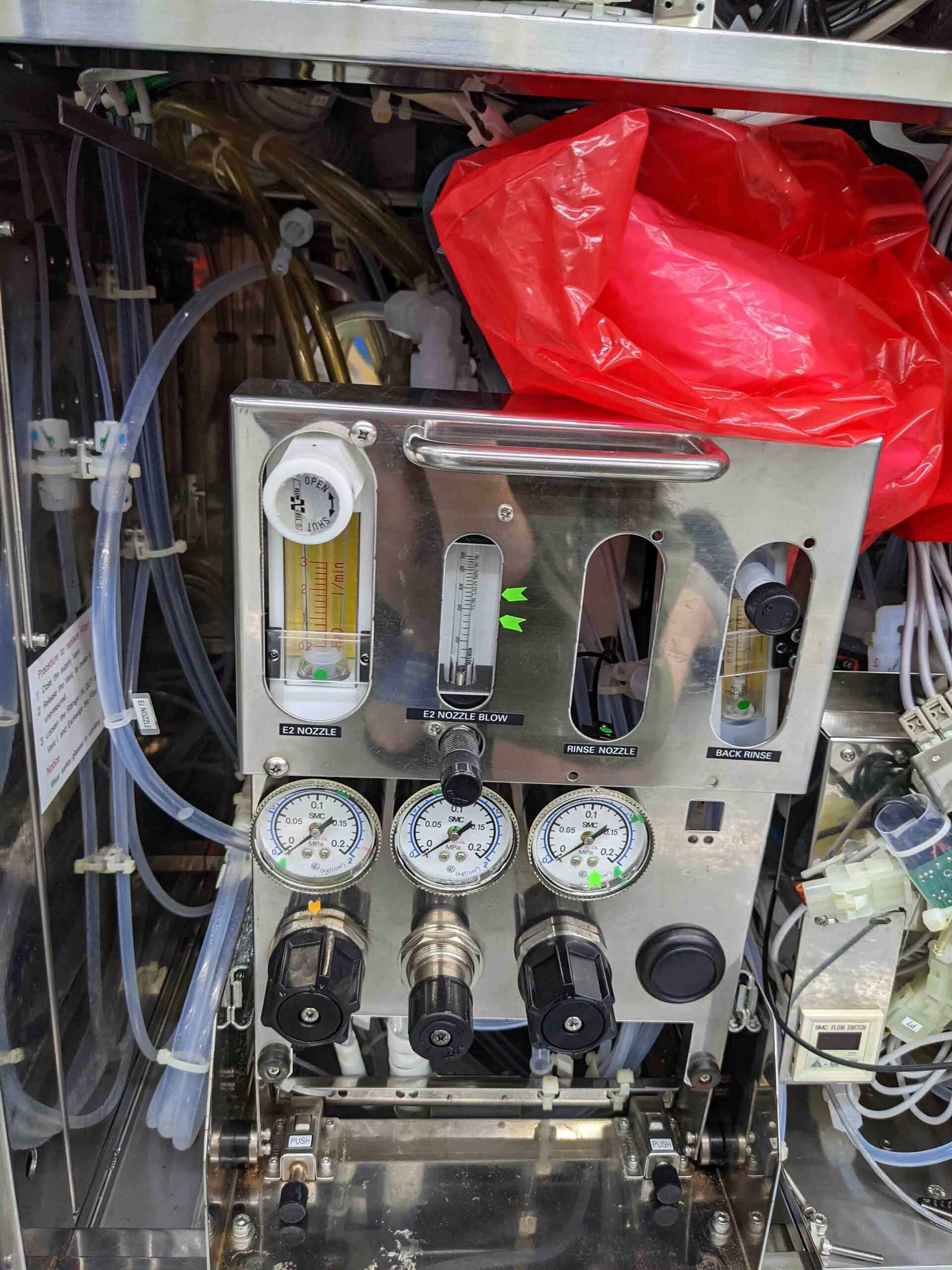

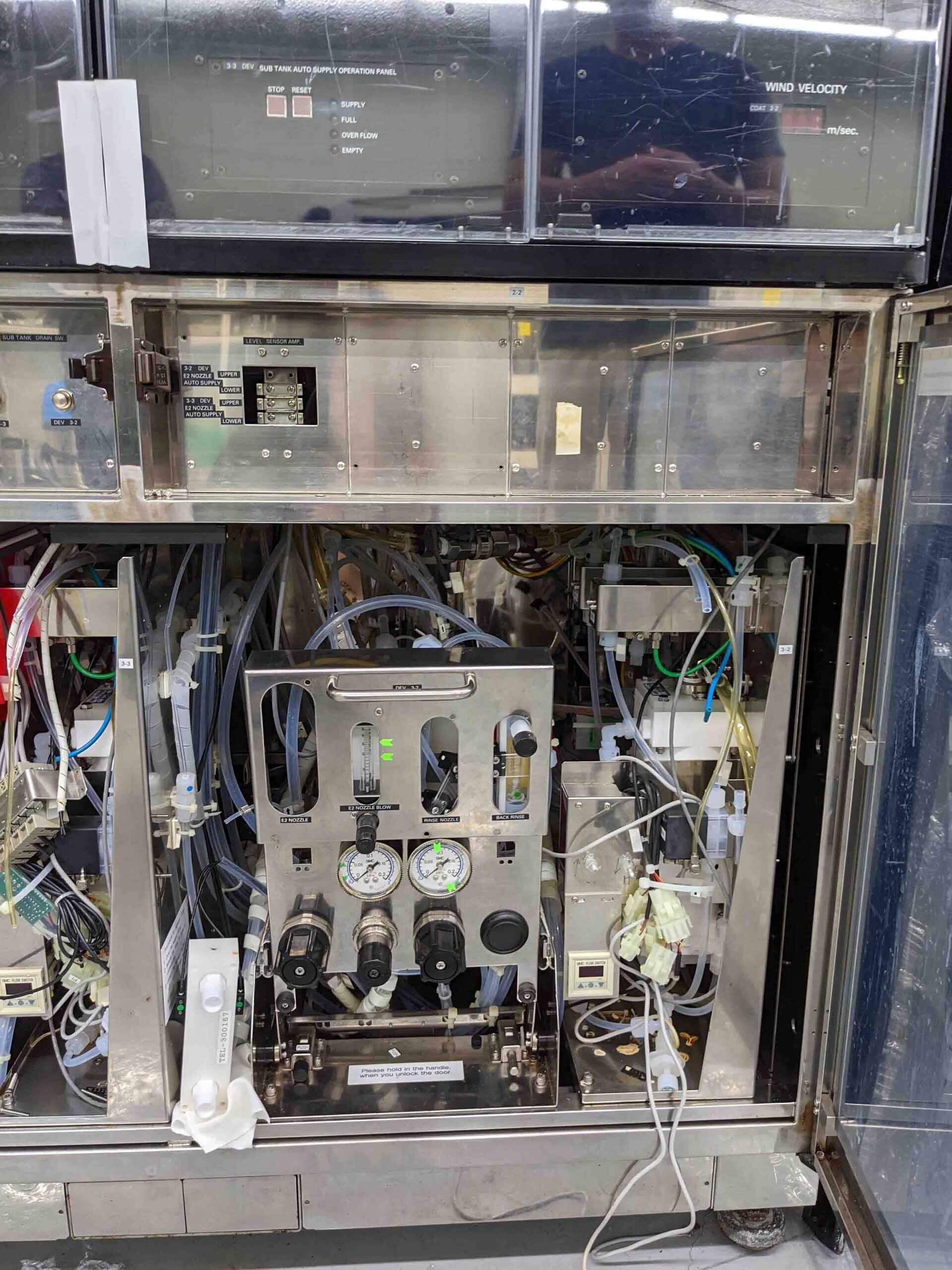

Block 3:

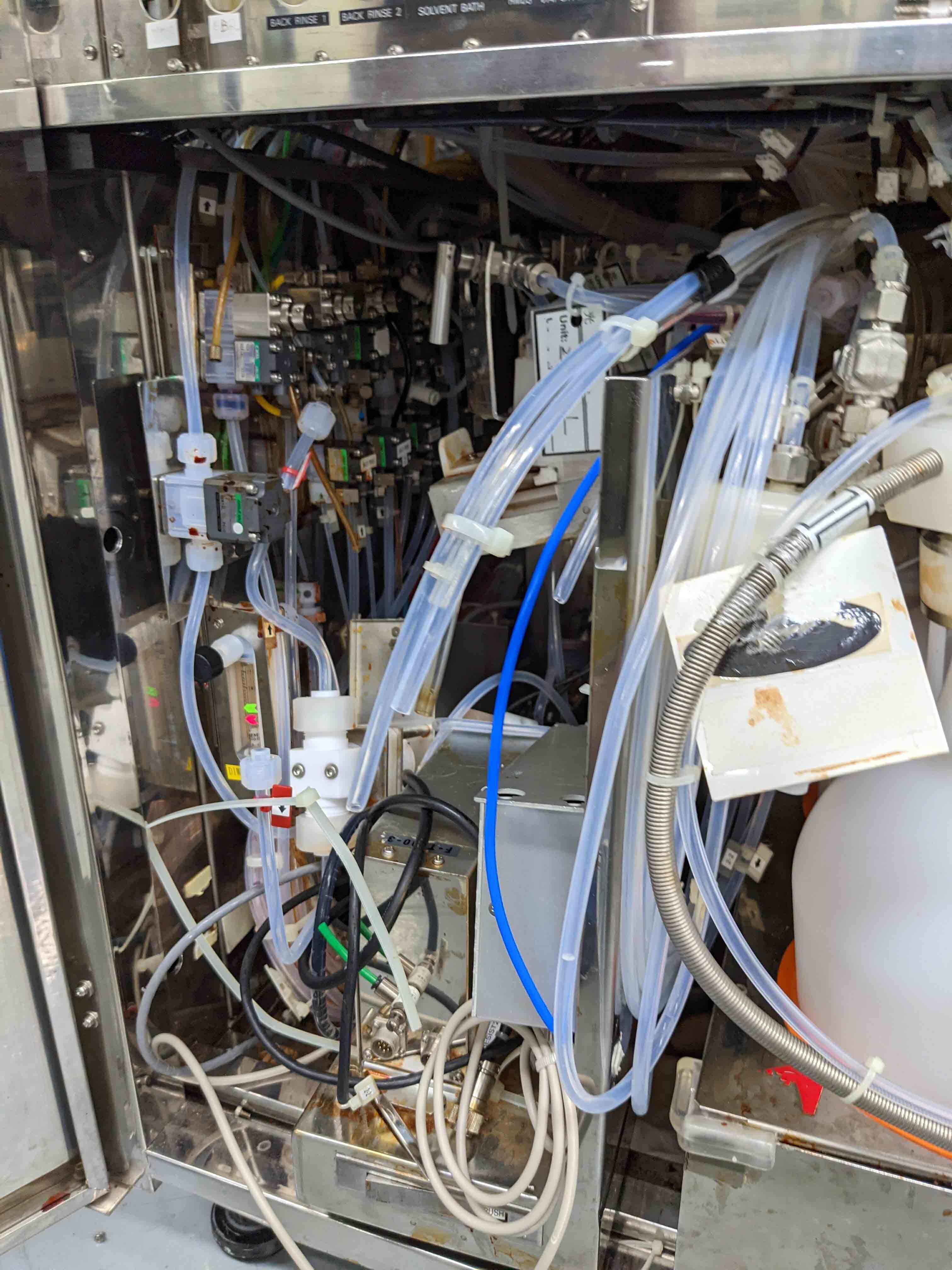

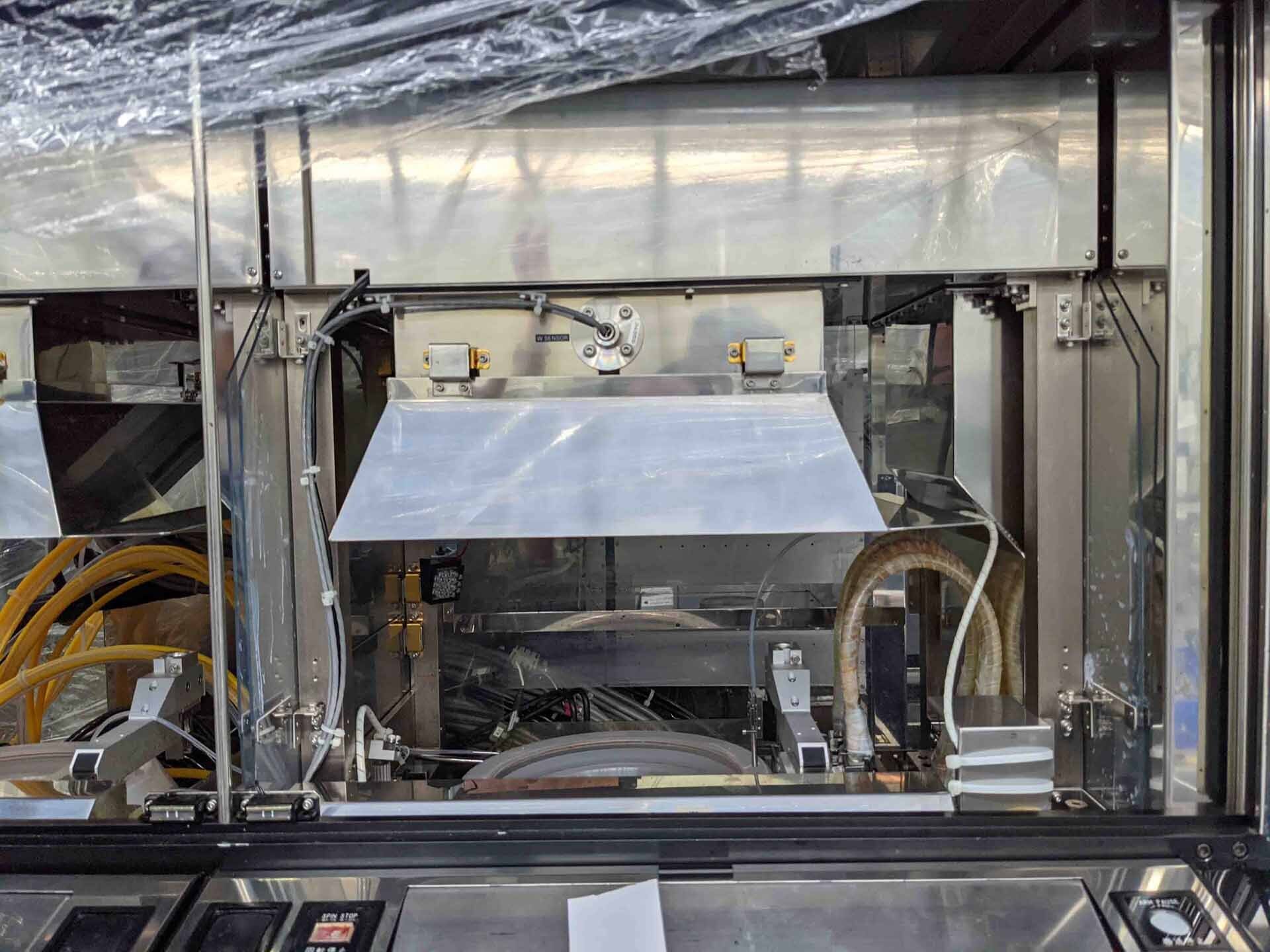

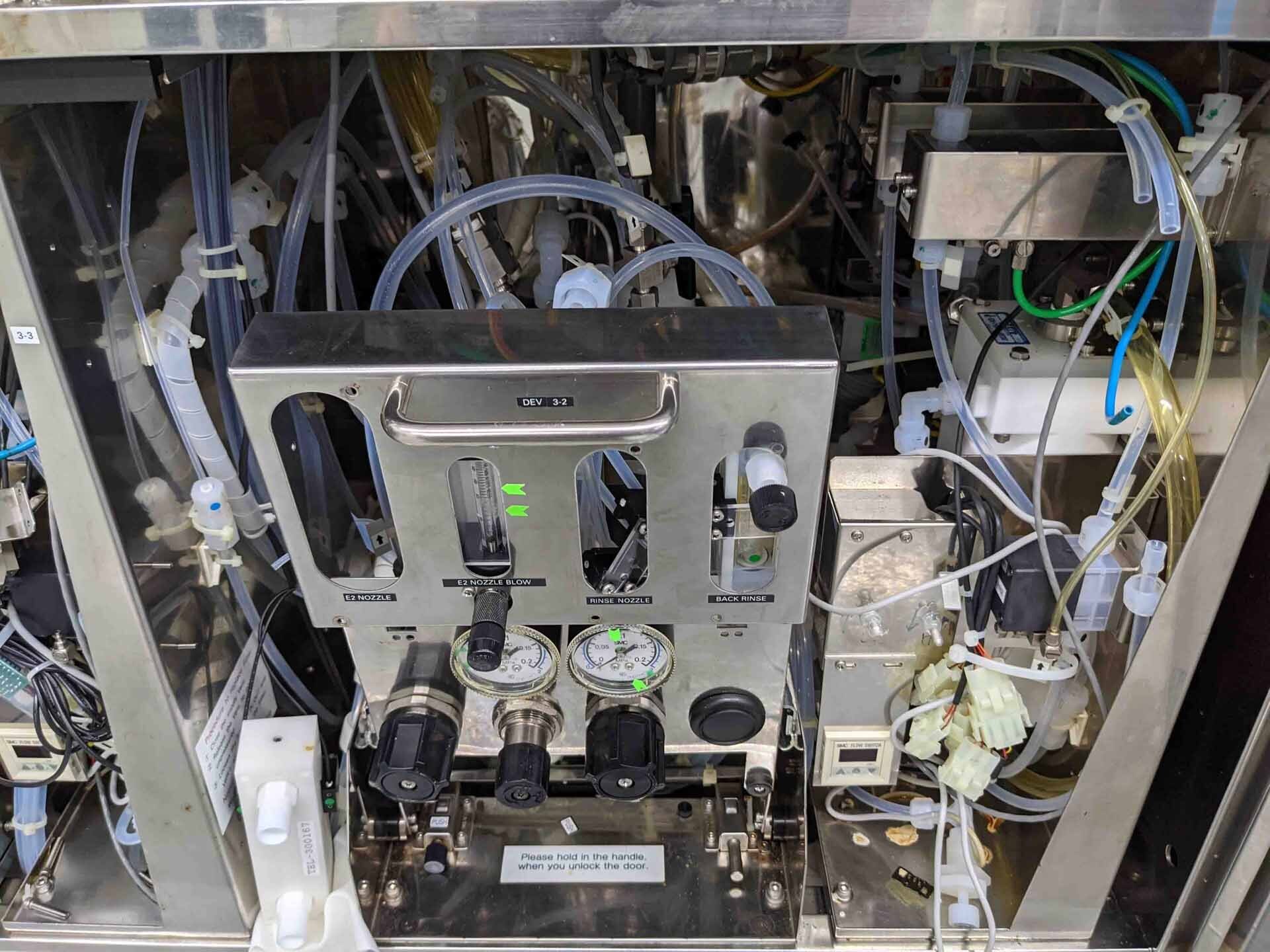

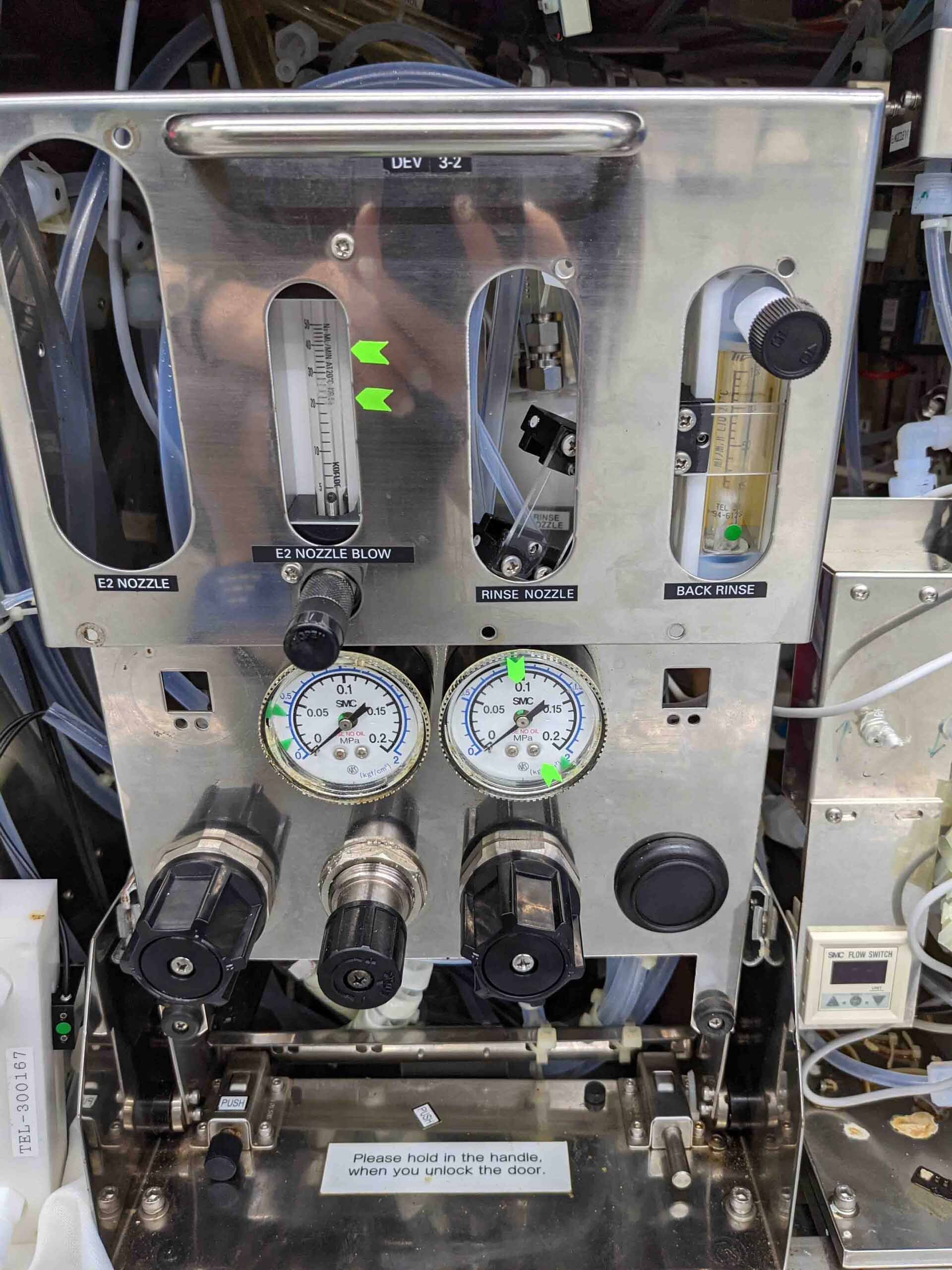

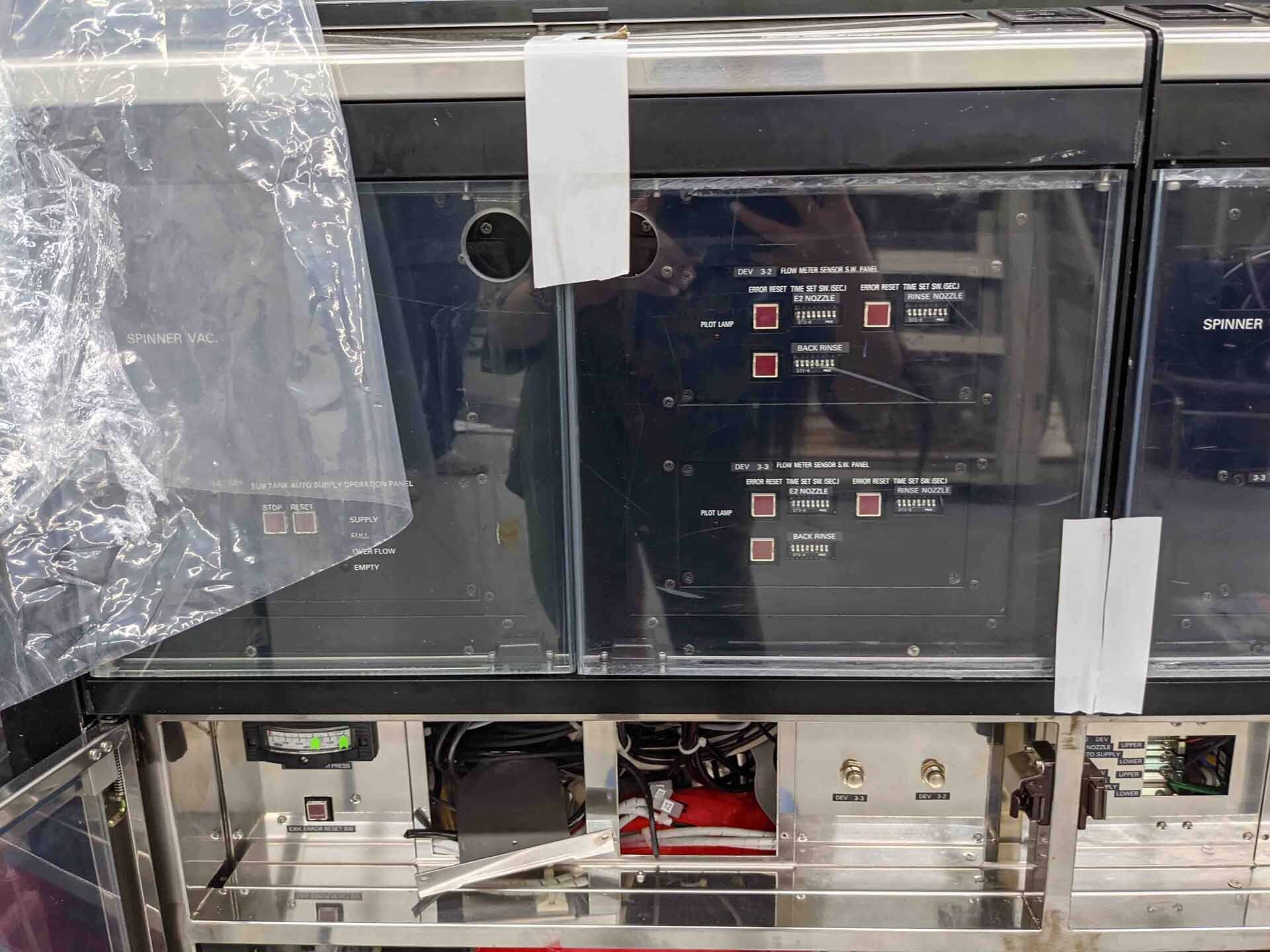

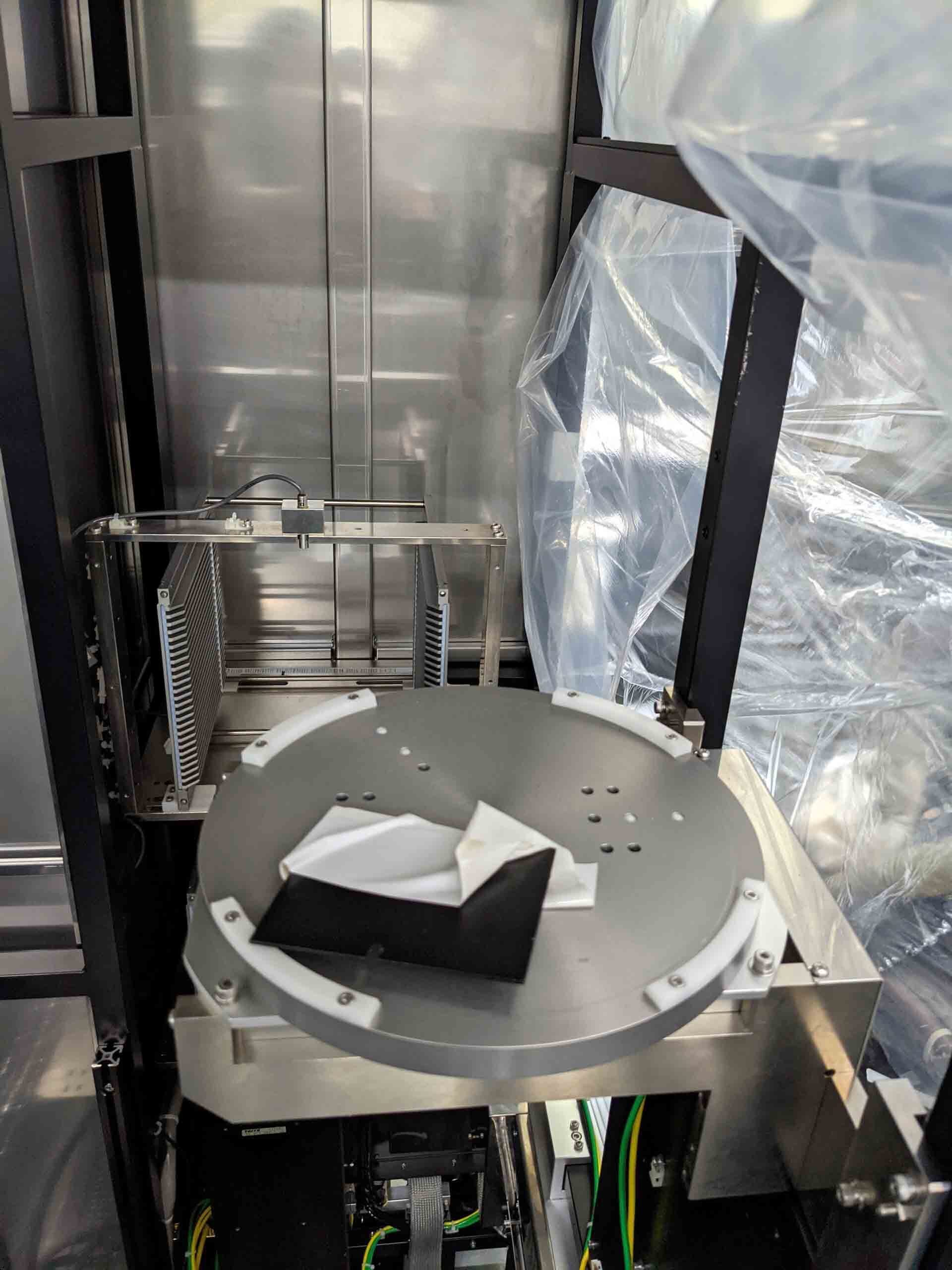

Developer 3-1, 3-2 Unit:

Single E2 nozzle

Dual top rinse nozzles

Back rinse nozzles

Developer temperature control

Motor flange temperature control

Drain type: Direct gravity

Auto damper

Auto dummy dispense system

Cup type: Stainless steel for upper and PP for inner

(2) Low temperature ovens (LHP)

(4) Cool plate units

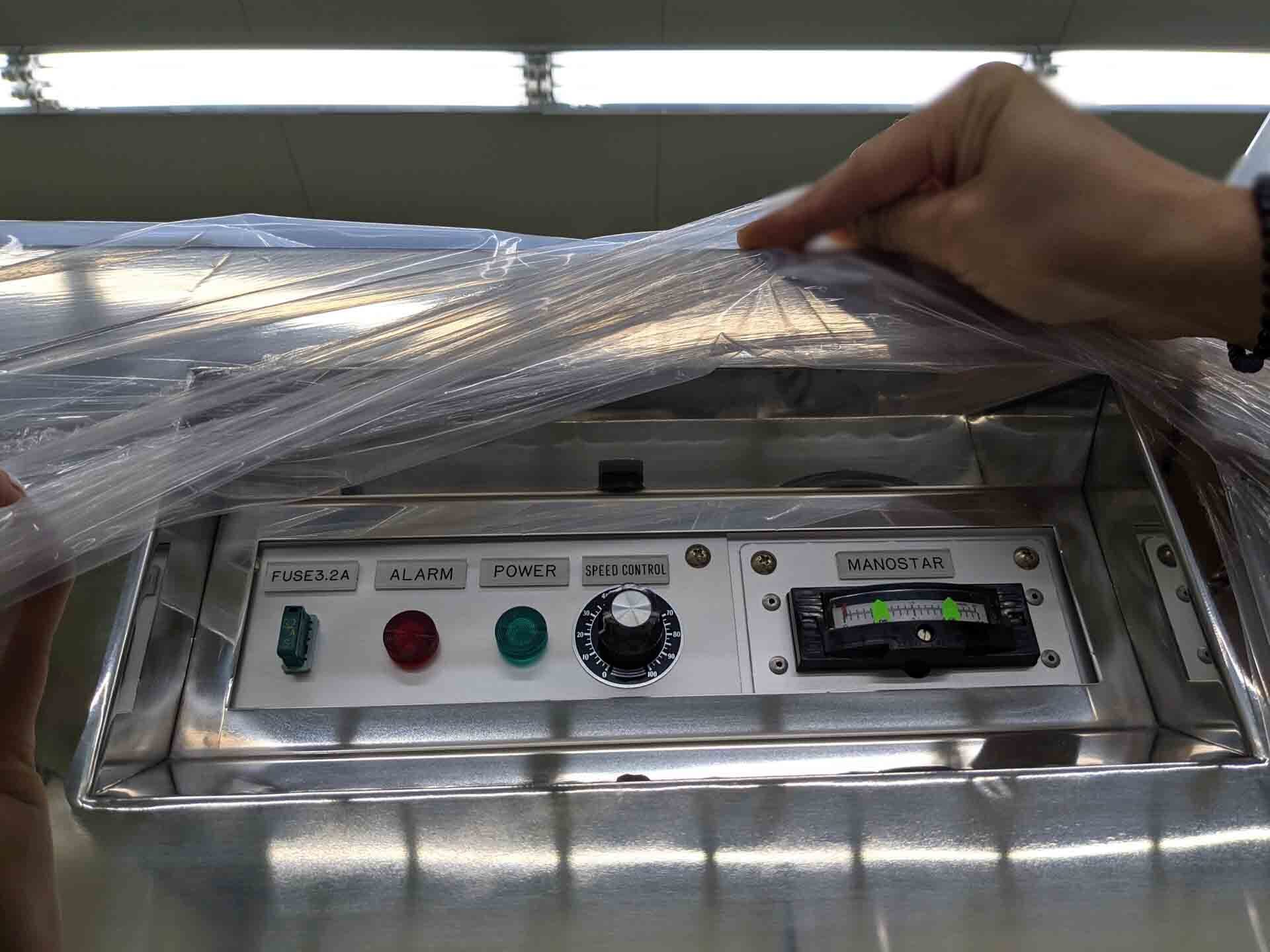

SHINWA Temperature and Humidity Controller (THC): 2-CUP

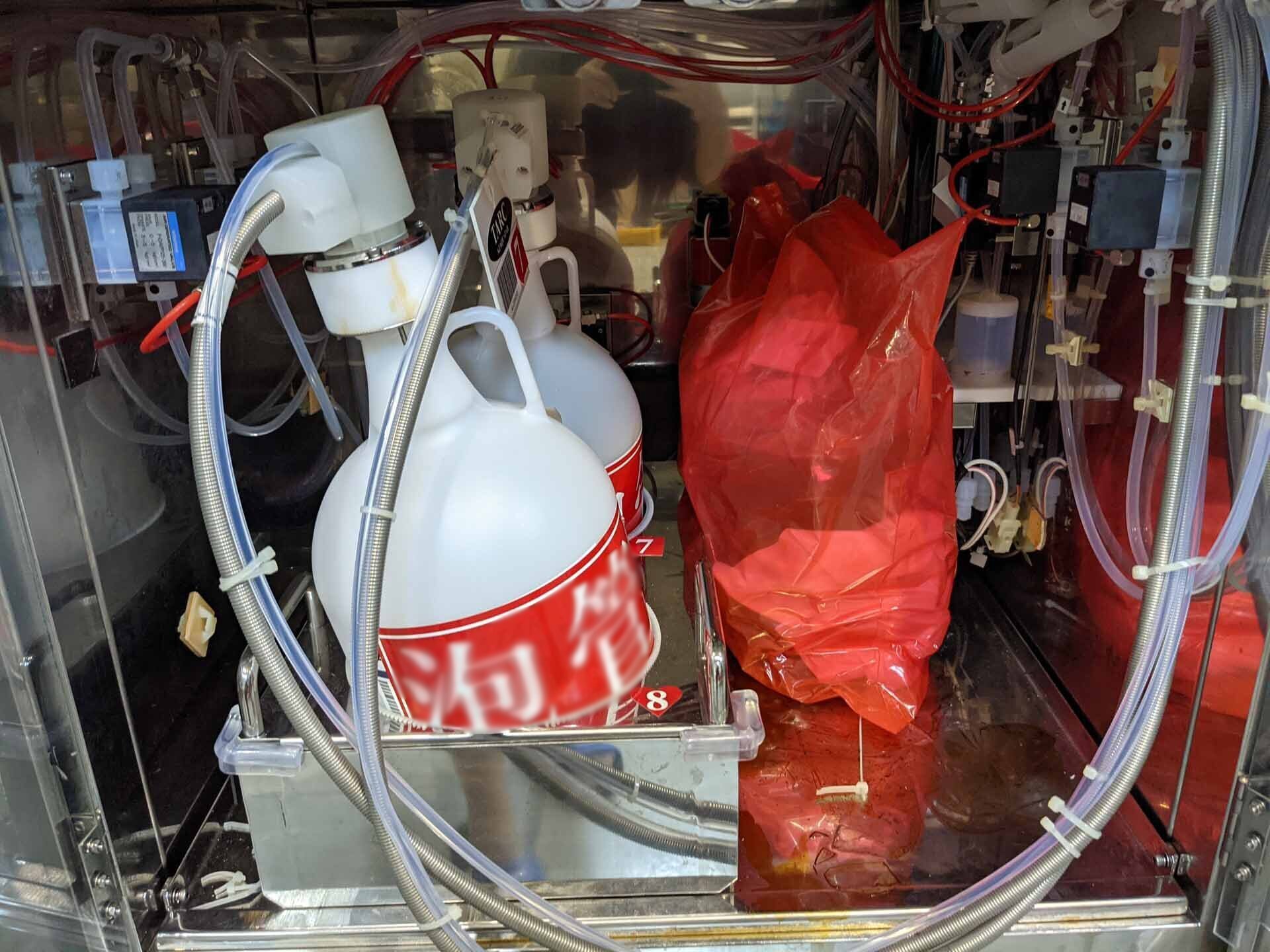

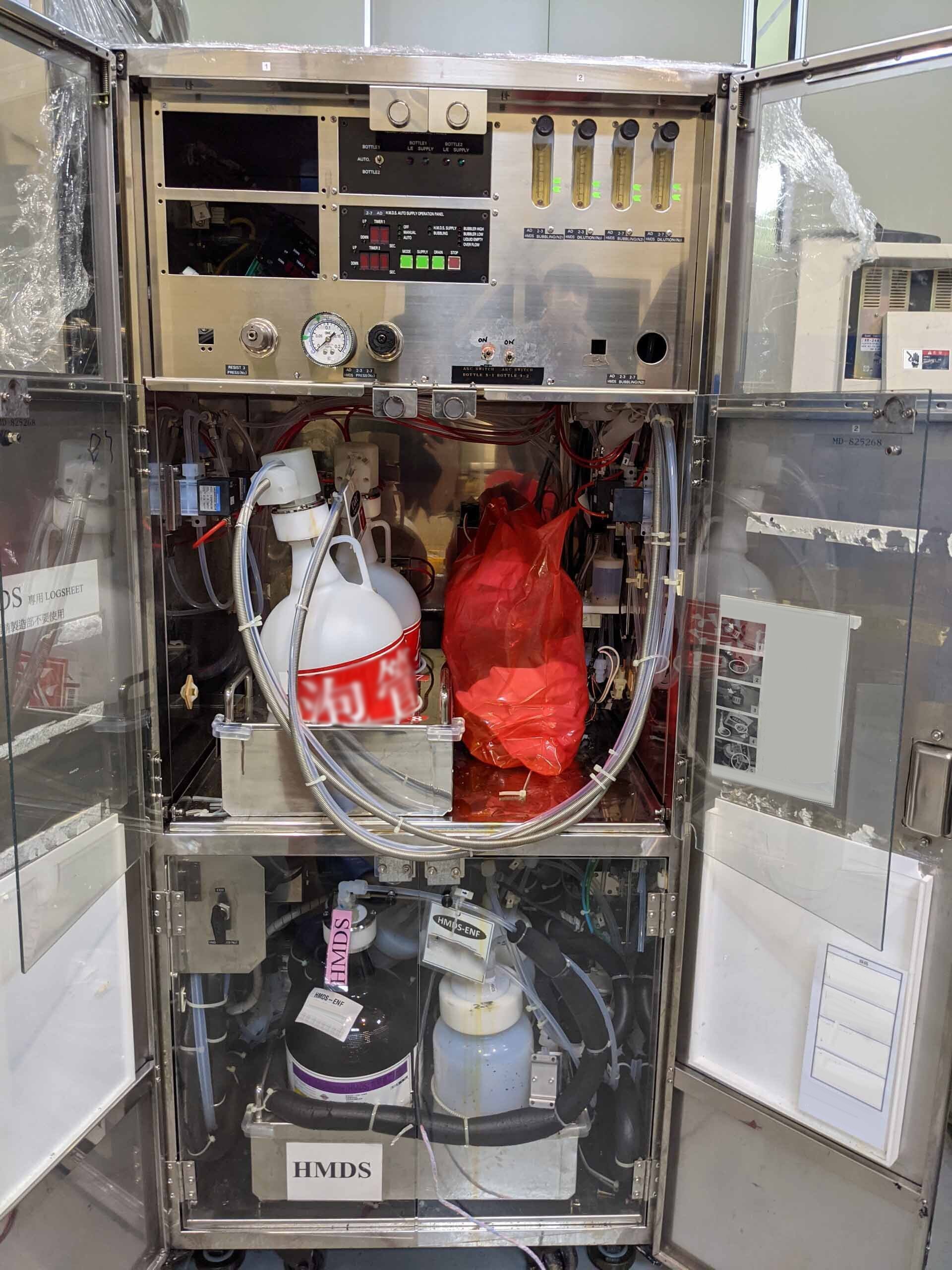

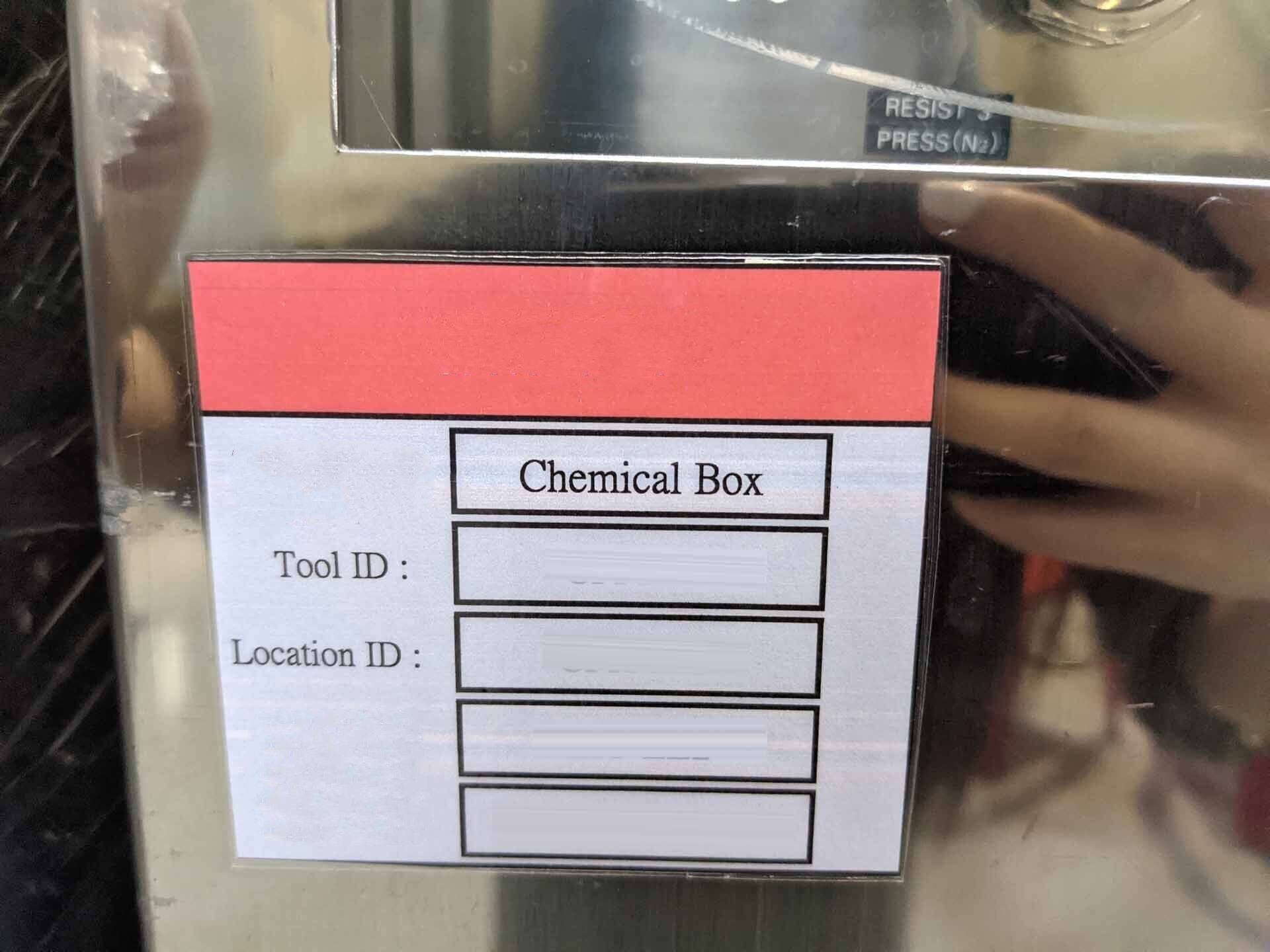

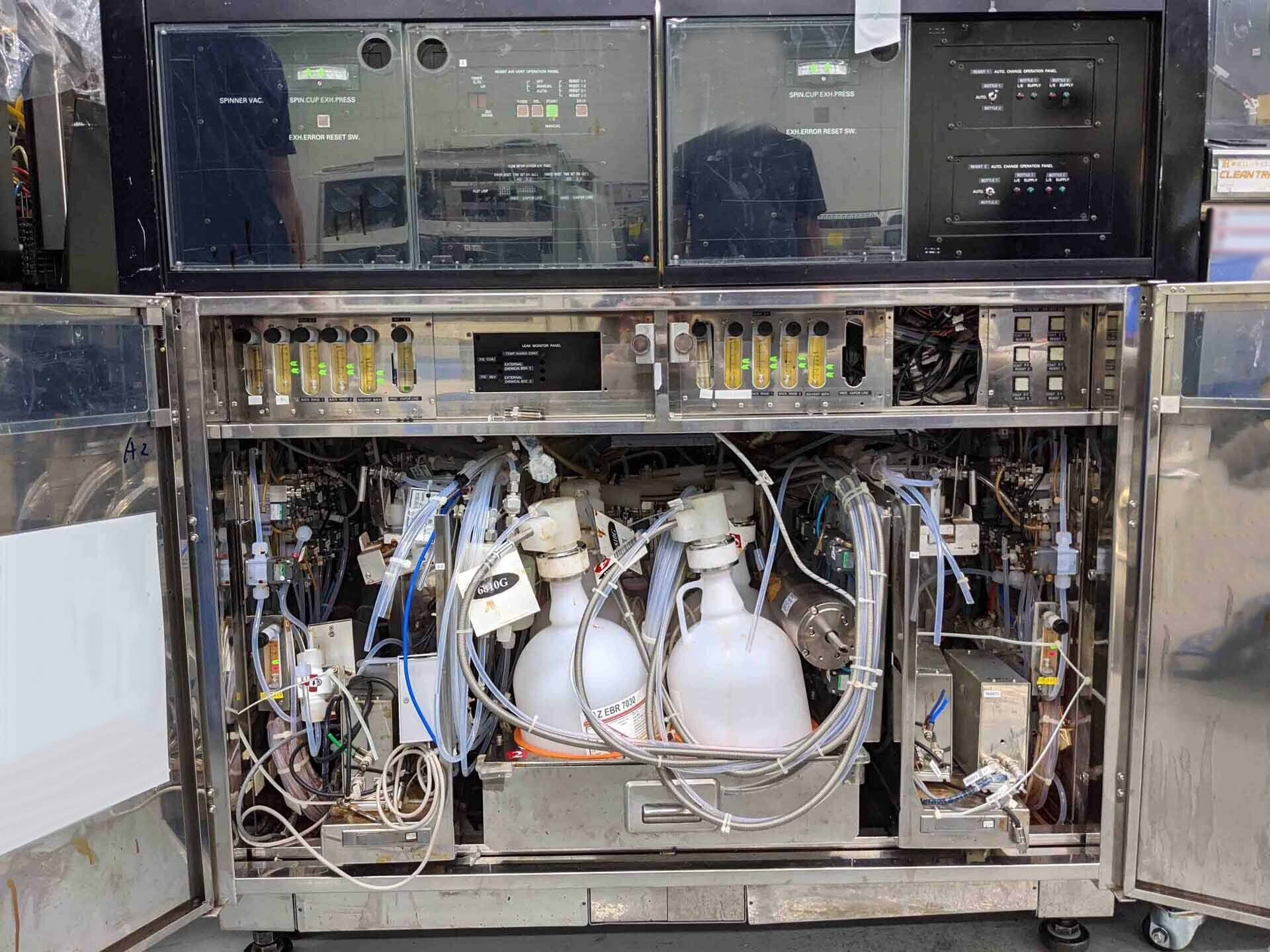

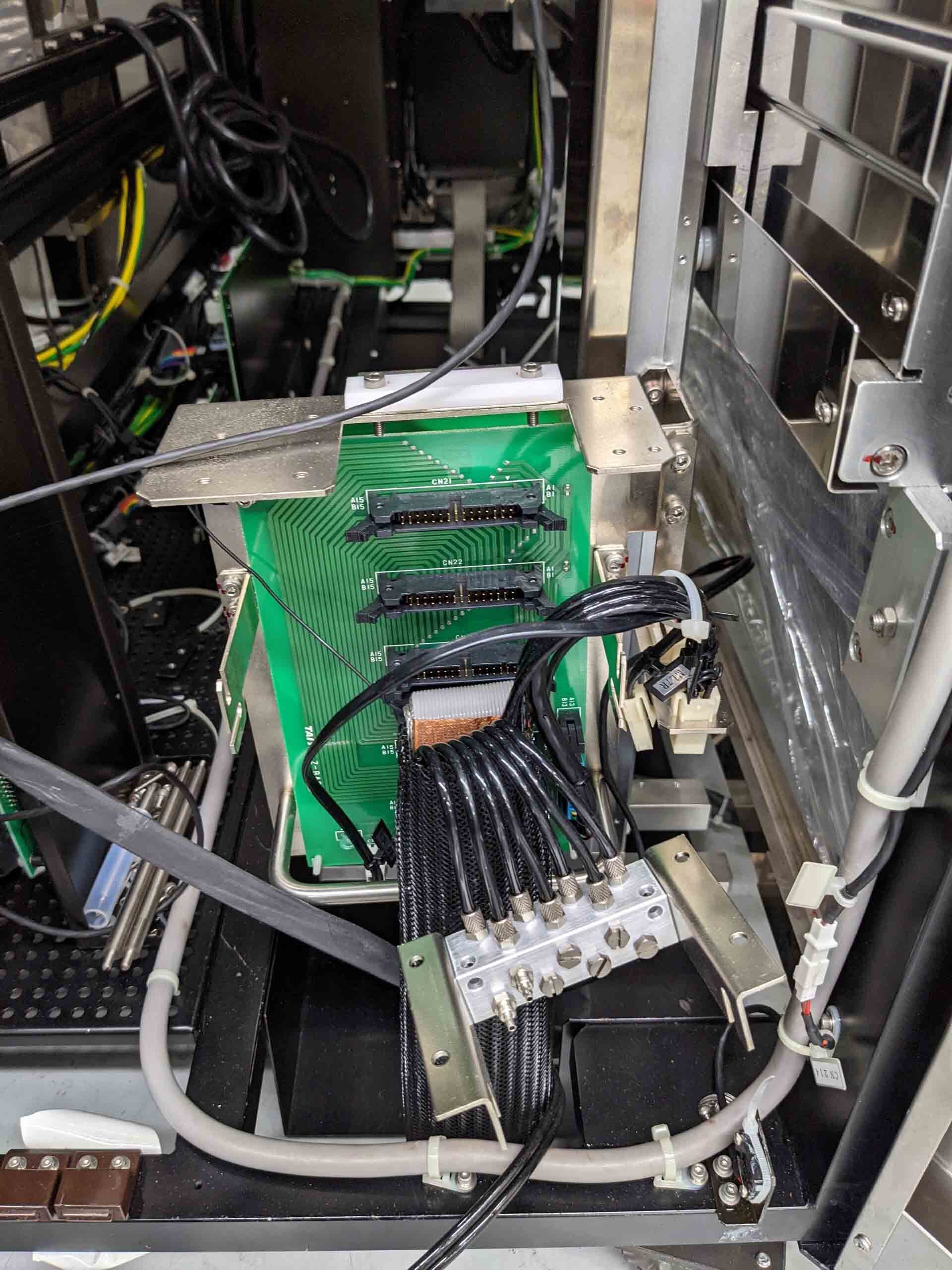

External chemical supply system:

Section-1: Solvent supply system

Solvent chemical type:

Chemical Center Supply System (CCSS)

With (2) of 3-litres teflon buffer tank

Type: (2) Buffer tanks (3litre/Tank, teflon) (2) Coaters

Tank auto switch off / Exchange

Section 2: Develop:

Develop chemical type

Chemical Center Supply System (CCSS)

With (2) of 3-litres teflon buffer tank to cover (2) DEV Units

Tank auto switch-off / Exchange

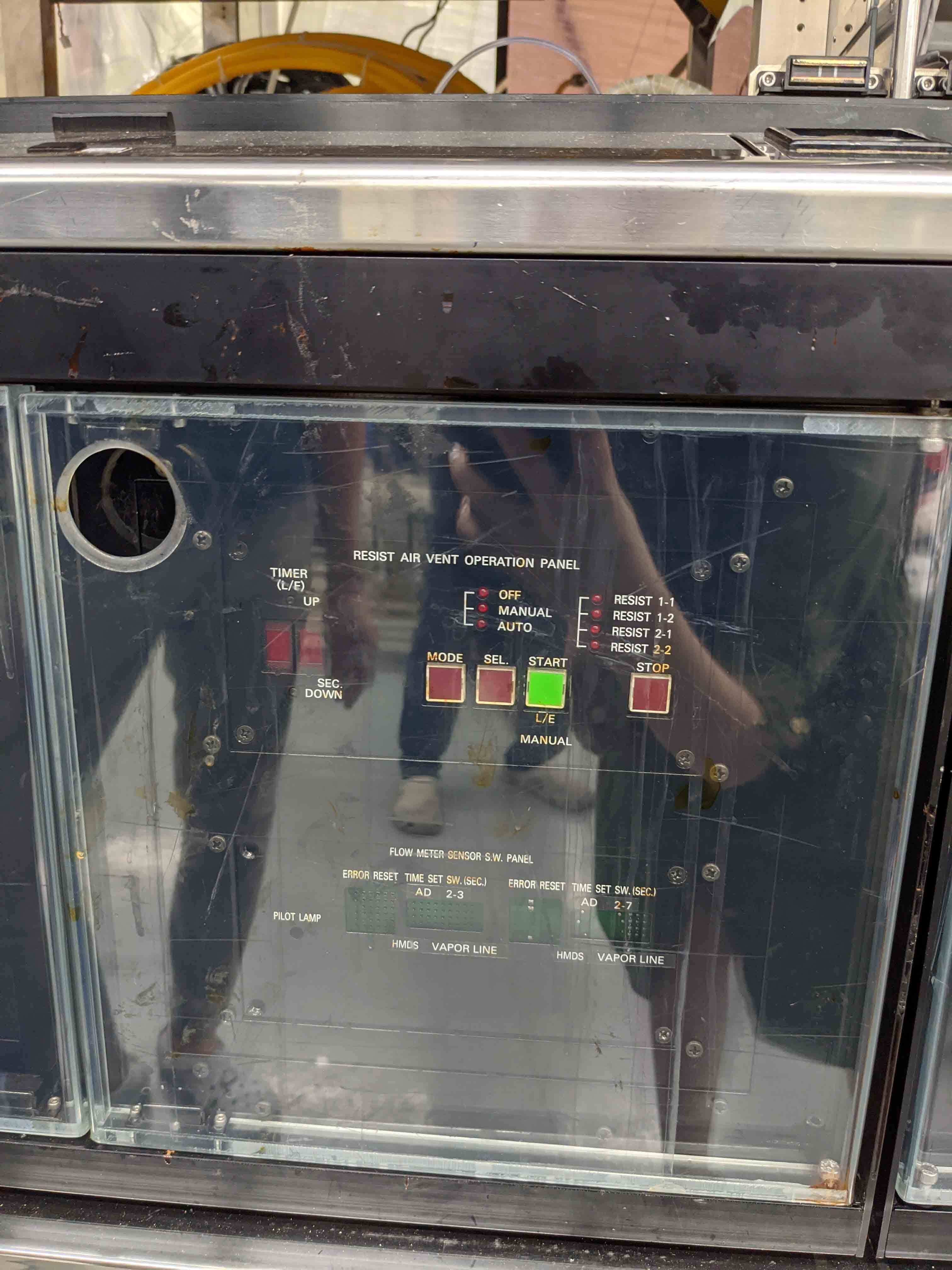

HMDS Supply system for 2 AD Unit:

Chemical type

1/4-Gal bottle

With 1L Buffer tank per ADH

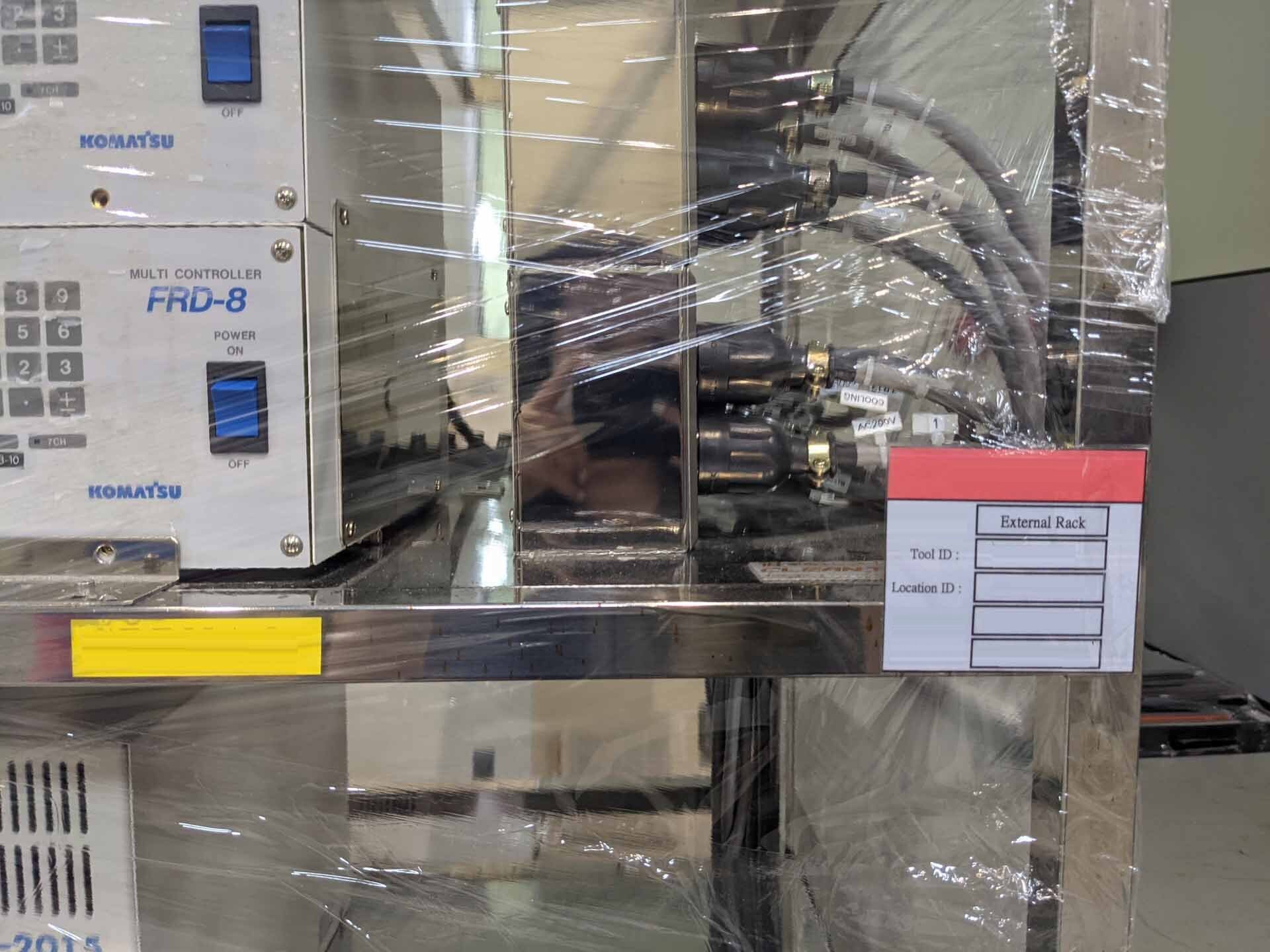

SMC Multi controller: Rear mail body

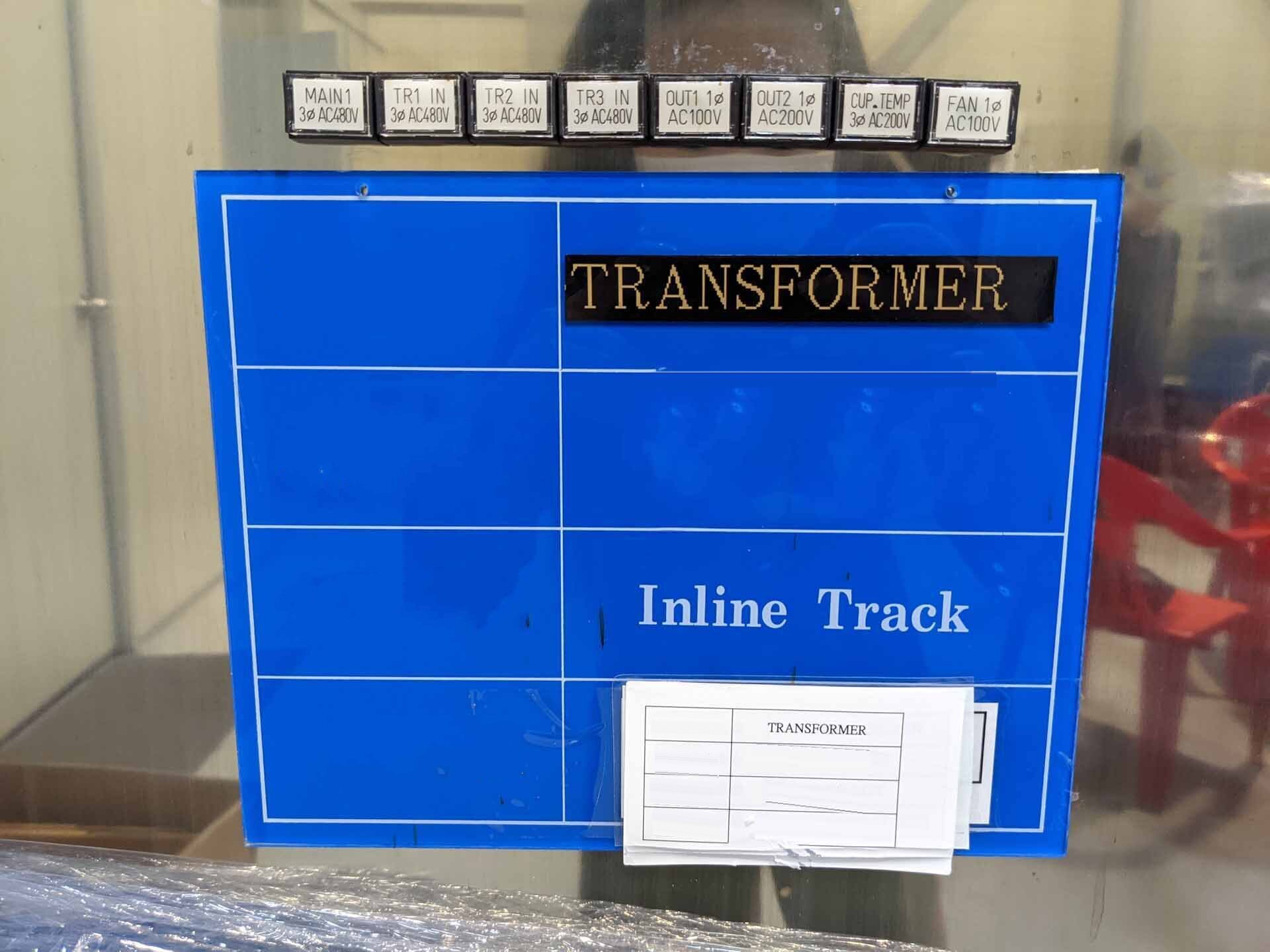

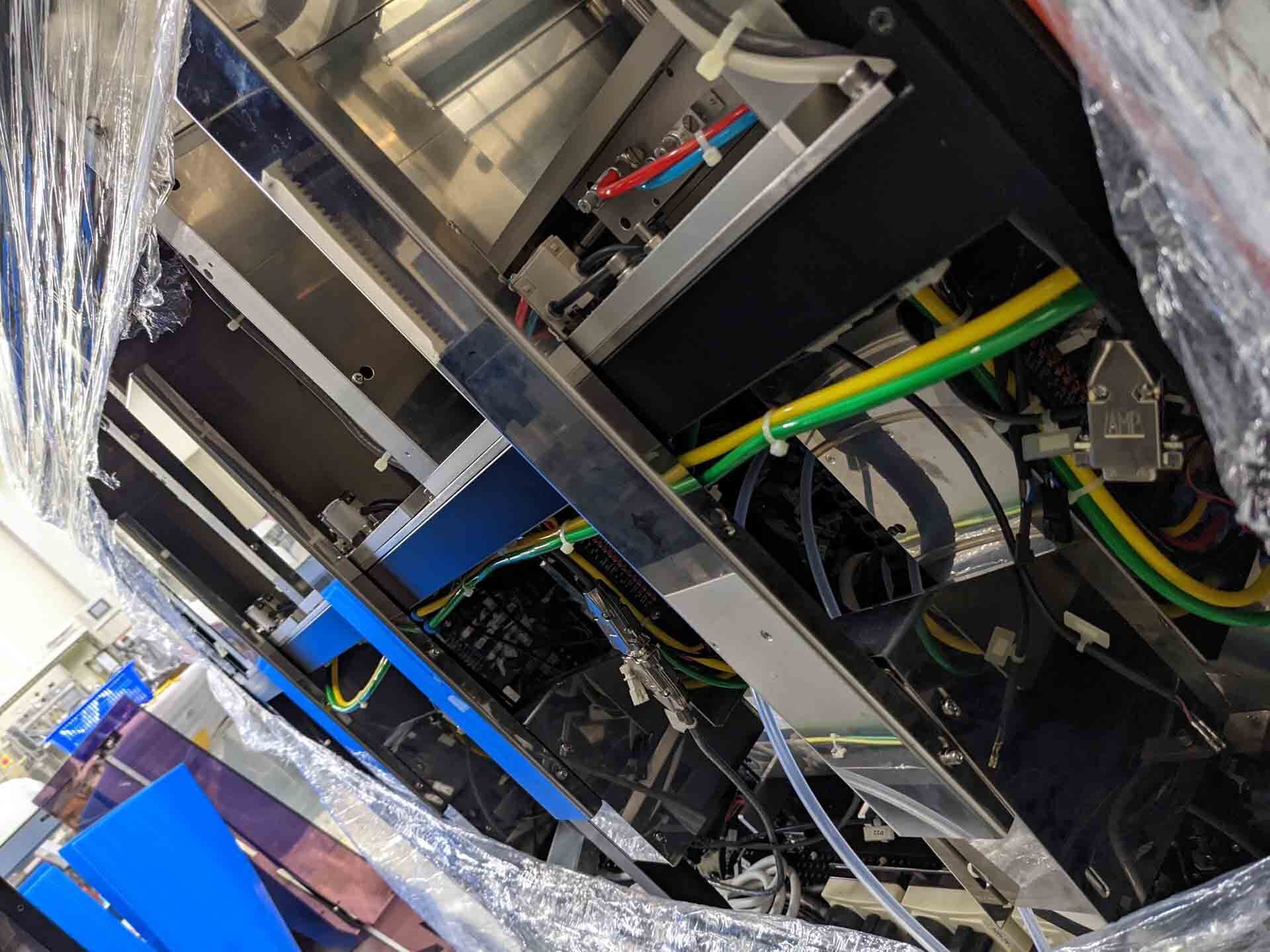

Power transformer AC cabinet : 208 VAC, 3 Phase, 50/60 Hz

ASML

(6) Hot transfer plates: HP3-4 / HP3-5 / HP 3-7 / HP 3-8 / HP2-4 / HP 2-8

(5) Cold transfer plates: COL2-9 / COL2-10 / COL3-6 / COL3-9 / COL3-10

Does not include Hard Disk Drive (HDD)

Missing parts:

CSB Unit:

X, Y, Z Theta motor

Y, Z Motor driver

FFU

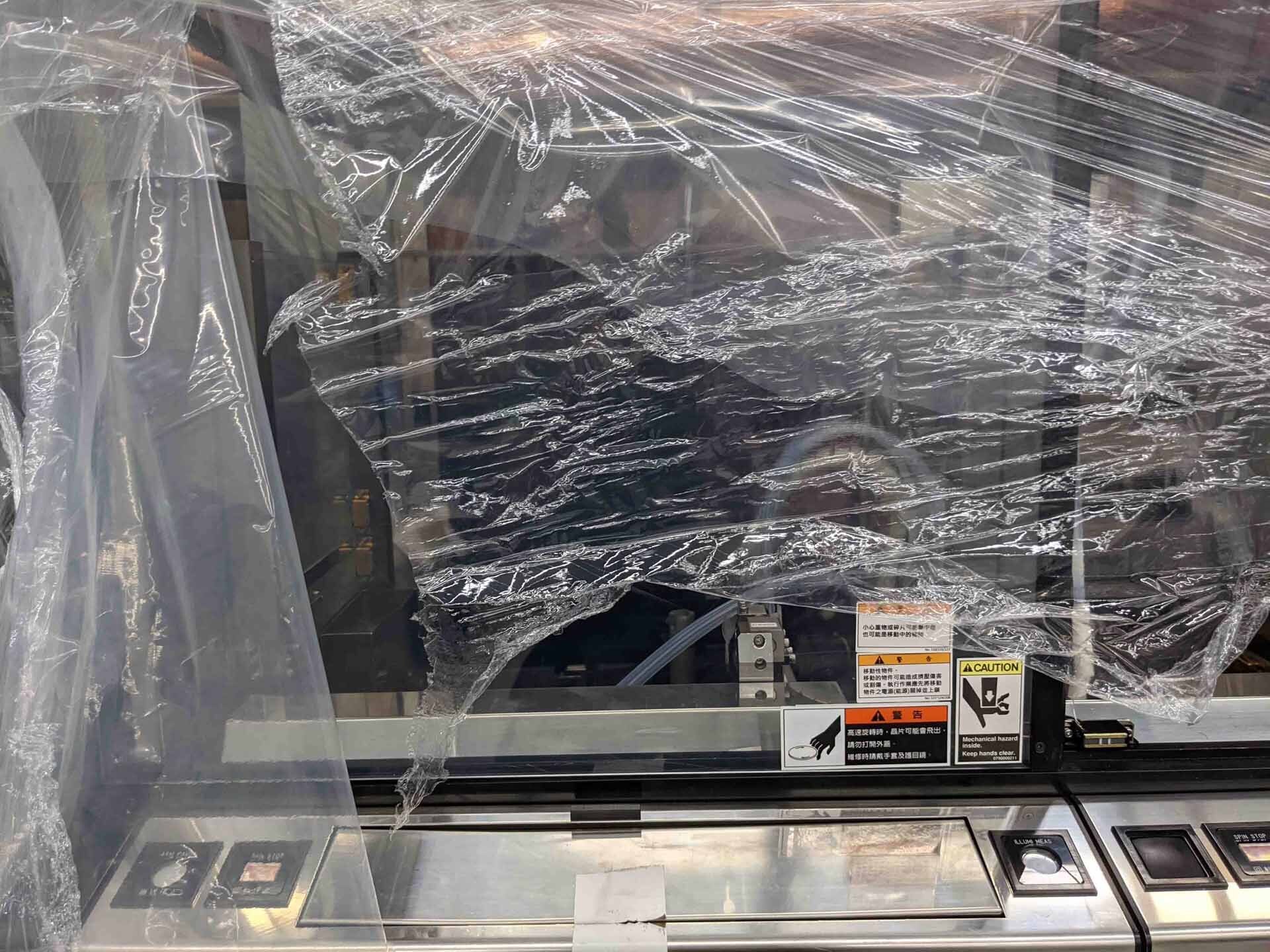

COAT 2-1:

EBR Cylinder

Spin chuck

RRC Pump

Spin motor driver

Spin connection board

VAC Sensor

(4) Solenoid valves

COAT 2-2:

EBR Cylinder

Spin chuck

RRC Pump

Spin motor driver

VAC Sensor

(11) Solenoid valves

DEV 3-1:

DEV Spin motor and driver

DI Rinse arm cylinder

Spin unit base assembly

DEV Cup

Spin chuck

Spin connection board

Solenoid valve mainfold

VAC Sensor

D.I Rinse flow meter

(4) Flow meter sensors

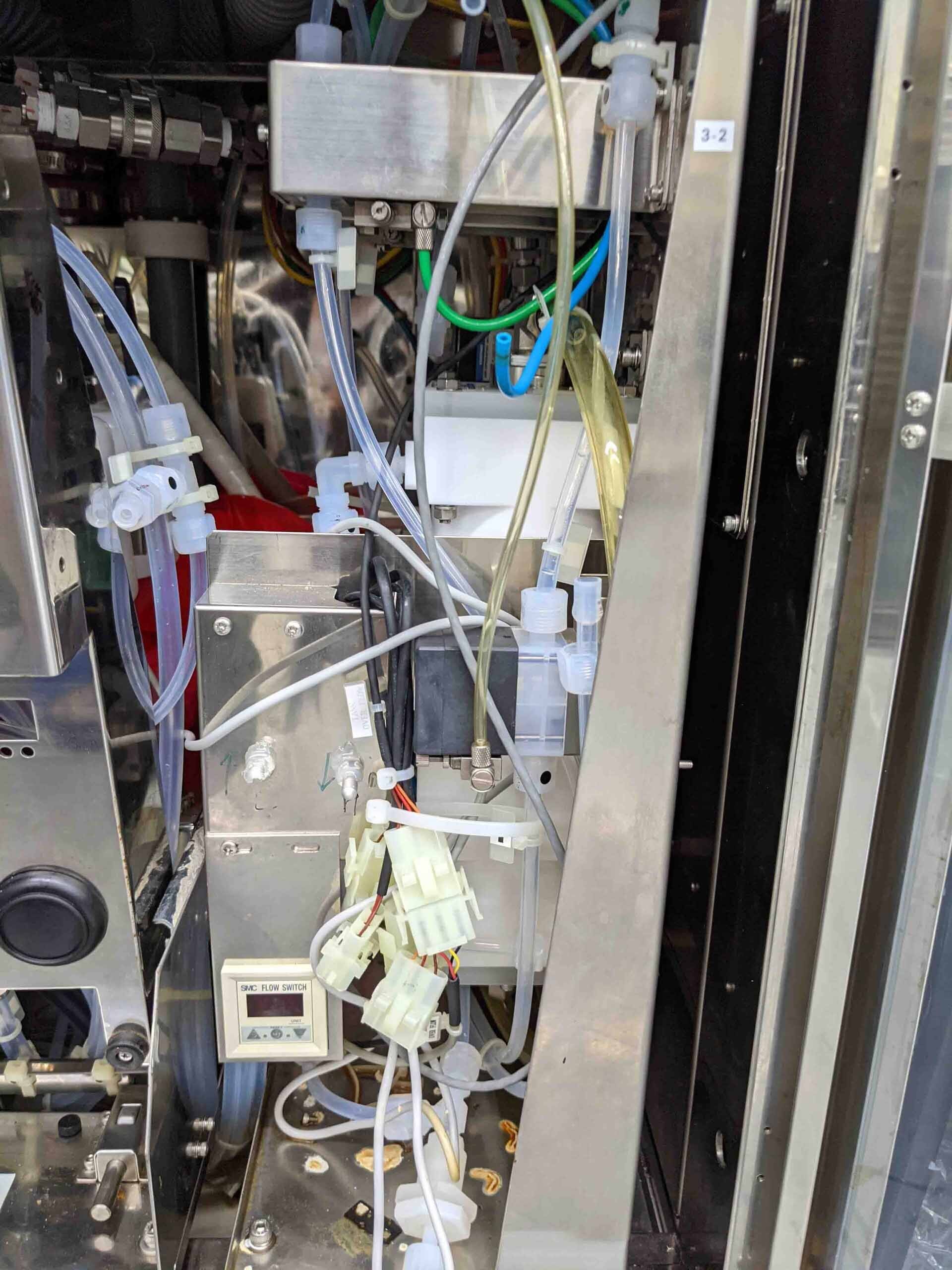

DEV 3-2:

DEV Spin motor and driver

DI Rinse arm cylinder

Spin unit base assembly

DEV Cup

Spin chuck

Spin connection board

VAC Sensor

IFB:

Arm assembly

(2) Trabot arms for ASML

Y, Z Motor driver

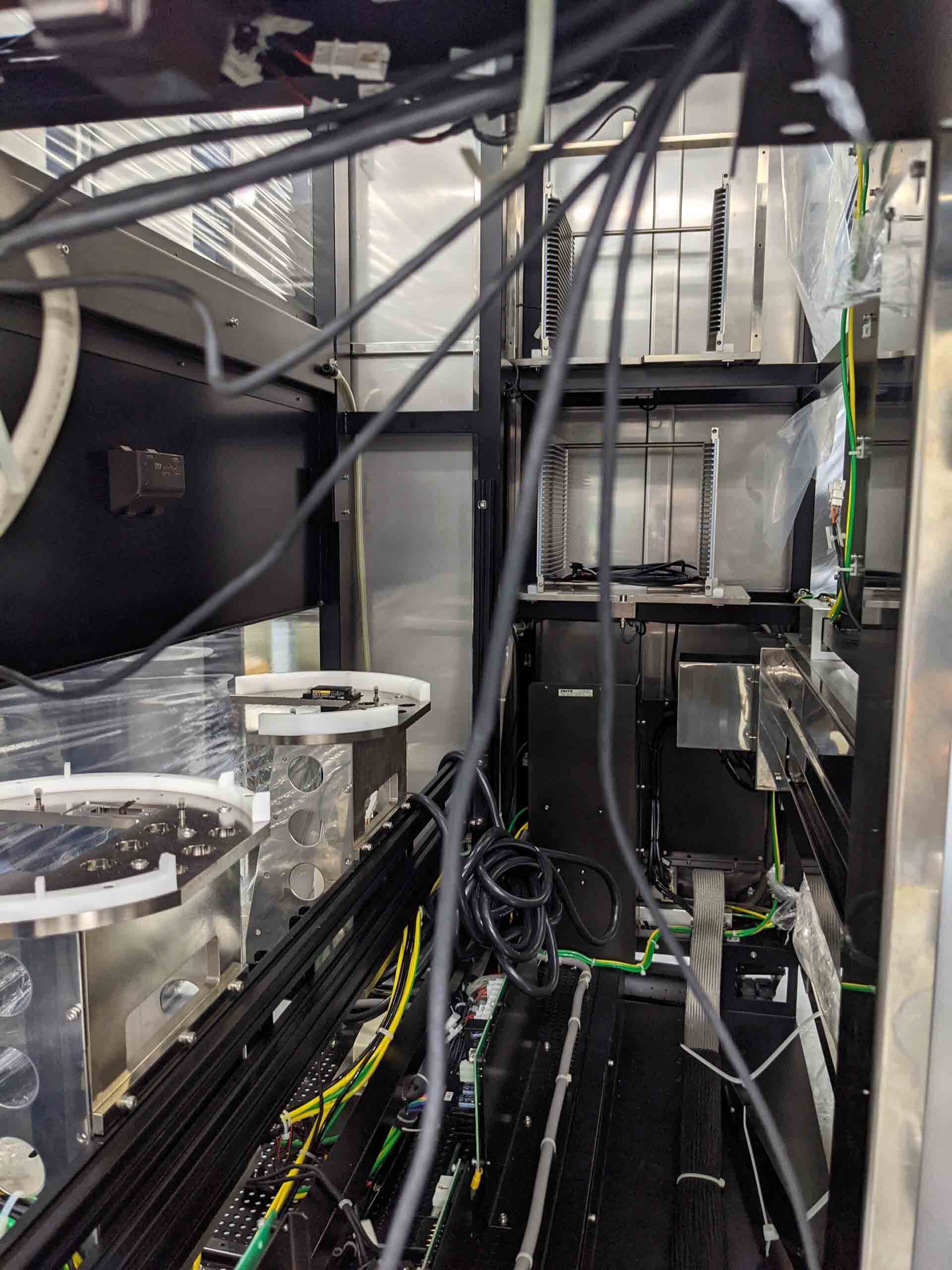

2-Block system:

FFU

Main arm assembly

Y, Z Motor driver

SIMF Card

TVME Card

(2) AD Units

HP Unit

Circulator pump

(10) DC Power fuses

3-Block system:

FFU

Main arm assembly

Y-Z Motor driver

TVME Card

(2) CP Units

(2) CPL Powers

(3) HP Units

Circulator pump

(10) DC Power fuses

WEE Lamp house

(2) Temperature and humidity controllers

1995 vintage.

TEL/TOKYO ELECTRON CLEan Track Mark 8是一种用于先进半导体器件制造的自动化光刻设备,由TEL开发制造。它是一个集成的高吞吐量系统,提供一致、高质量的生产过程,并提高了速度和准确性。该装置配备了坚固、高效的清洁和涂层技术,旨在最大限度地减少颗粒产生和残留。机器的核心是Clean Track chamber,设计用于将晶片固定到位,确保制造过程中的可重复性。该室采用先进的腔室清洁技术和等离子体处理、化学清洁和先进的涂层技术相结合,以减少颗粒和其他残留物。Mark 8工具还配备了多种自动化功能,包括自动基板传输和处理、自动配方资产、自动基板验证以及对每个处理过的基板进行自动数据记录。该模型能够高精度地处理不同的基材尺寸、基材类型和形状。该设备还采用了先进的喷嘴设计,以利于光刻材料的最佳涂层和喷涂。此外,它还配备了先进的粒子检测系统,以确保颗粒或其他残留物含量高的底物不会进一步加工。TEL Clean Track Mark 8提供了一种低成本、高质量的光刻胶处理解决方桉,适用于一系列不同的先进设备制造工艺。它的模块化设计和组件实现了多功能性和成本效益。先进的气流和湿度控制为光刻涂层提供了理想的环境,自动处理基板最大程度地减少了污染。该系统还通过跟踪基板加工的变化和记录实时数据来实现工艺优化。

还没有评论