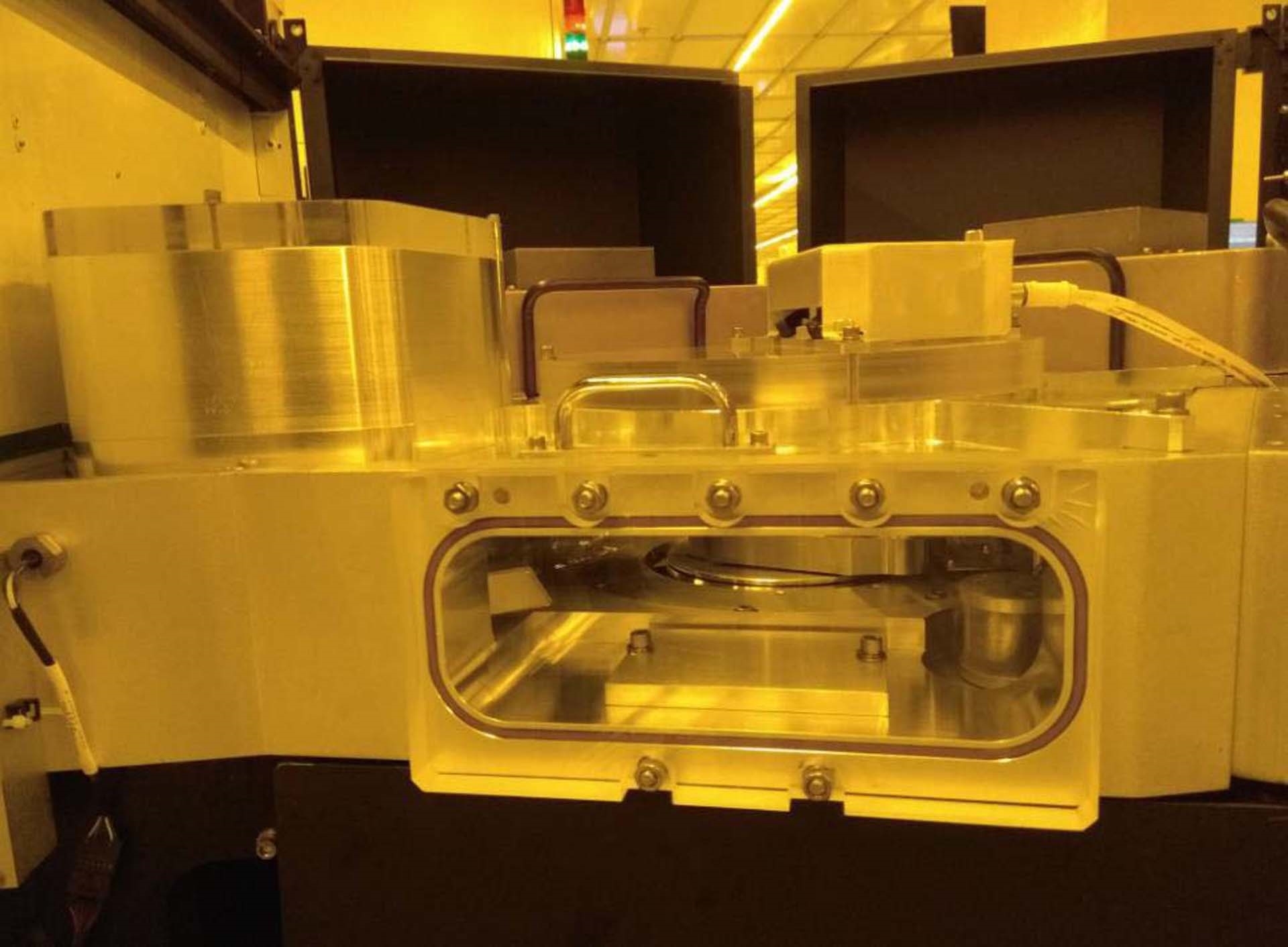

二手 AMAT / APPLIED MATERIALS P5000 #9236969 待售

网址复制成功!

单击可缩放

ID: 9236969

晶圆大小: 8"

优质的: 1998

PECVD System, 8"

Process: Passivation

Chamber type: DLH

CIM Linked

Main frame

Load lock

SMIF System: ASYST ARM-2200 V111S

Handler system: Robot assembly

Process chamber:

(3) CVD Deposition chambers A, B & C

(3) Primary generators

(3) RF2 Generators & matches

(4) Ebara pumps

Heat exchanger

Mini SBC board

SBC Board

SEI Board

(2) AI Boards

(2) AO Boards

VGA Board

(4) Stepper driver boards

(2) Digital I/O boards

Buffer I/O board

(2) Optical sensor boards

(4) Chopper driver boards

(3) Baratrons

LAMDA Power supply

Hard Disk Drive (HDD)

Wiring distribution board

Pneumatic board

Loader interconnect board

(2) TC Gauge boards

+12V DC Power supply

+15V DC Power supply

-15V DC Power supply

AI MUX Board

(3) RF Generators

Controller distribution board

Encoder interface board

System electronic back plane

Robot blade assembly

Facility:

A10S Loadlock pump

A70W Process pump

Incoming power: 208 VAC

Heat exchanger temperature set point: 65

Buffer:

LPT / Indexer: ARM-2200 H112S

Center finder

Storage elevator: (8) Slots

LL Robot type: Metal

Load lock actuator: IO Door

Chamber actuator: 0010-70162

CDA Pressure for buffer: 60 psi

Process chamber:

RF 1 Generator: ENI OEM-12B

RF 2 Generator: RFPP 7520572050

RF Match: AMAT / APPLIED MATERIALS Automatch 0010-09750

Pressure manometer: MKS 10T (122BA-001000EB-S)

Throttle valve / PCV Model: VEXTA PX245-02AA-C4

TC Part number: 3310-01074

Chuck type: P-Chuck

Chuck part number: 0010-38437

Process temperature: 400°C

MFC Gases:

C2F6: 10 SLM

SIH4: 3000scc

NH3: 300scc

N2: 10 SLM

N20: 3000 SCC

N20 (G): 200 SCCM

PH3: 300 SCC

DPA Included

Endpoint: 0190-09472

CDA Pressure for chamber: 60 psi

1998 vintage.

AMAT/APPLIED MATERIALS P5000是一种用于制造半导体器件的反应堆。它利用先进的技术提供精确的热控制和化学气相沉积(CVD)的平台。反应堆的设计目的是确保均匀的温度,减少整个材料或装置生长过程中的不均匀性。AMAT P-5000是一种单晶片反应器,它包含三个关键特征:均匀性、温度控制和基板柔韧性。反应堆由几个部件组成:石英室、感应座、控制设备、加热元件和冷却系统。石英室允许在受控条件下将膜氧化或沉积到基板上。磁感器安装在处理过程中保持晶片,设计为提供均匀的温度分布。该控制单元可实现精确的温度控制和CVD平台。加热元件设计为通过整个晶片提供均匀的温度。冷却机用于降低基板温度,使工艺稳定。APPLIED MATERIALS P 5000反应堆有着广泛的优势,如性能增强、重复性高、吞吐量提高、产量提高等。它还能够在高温下生产设备,具有极好的均匀性和可重复性。此外,P5000反应器是晶片键合的理想选择,因为它可以确保非常均匀的温度和更高的处理精度。最后,AMAT P5000反应器是半导体制造过程中的重要组成部分.它能够提供均匀的温度并减少材料或设备整个生长过程中的不均匀性,这使得它极为有用和具有成本效益。随着技术的进步,预计P 5000反应堆将在生产半导体器件方面变得更加先进和高效。

还没有评论