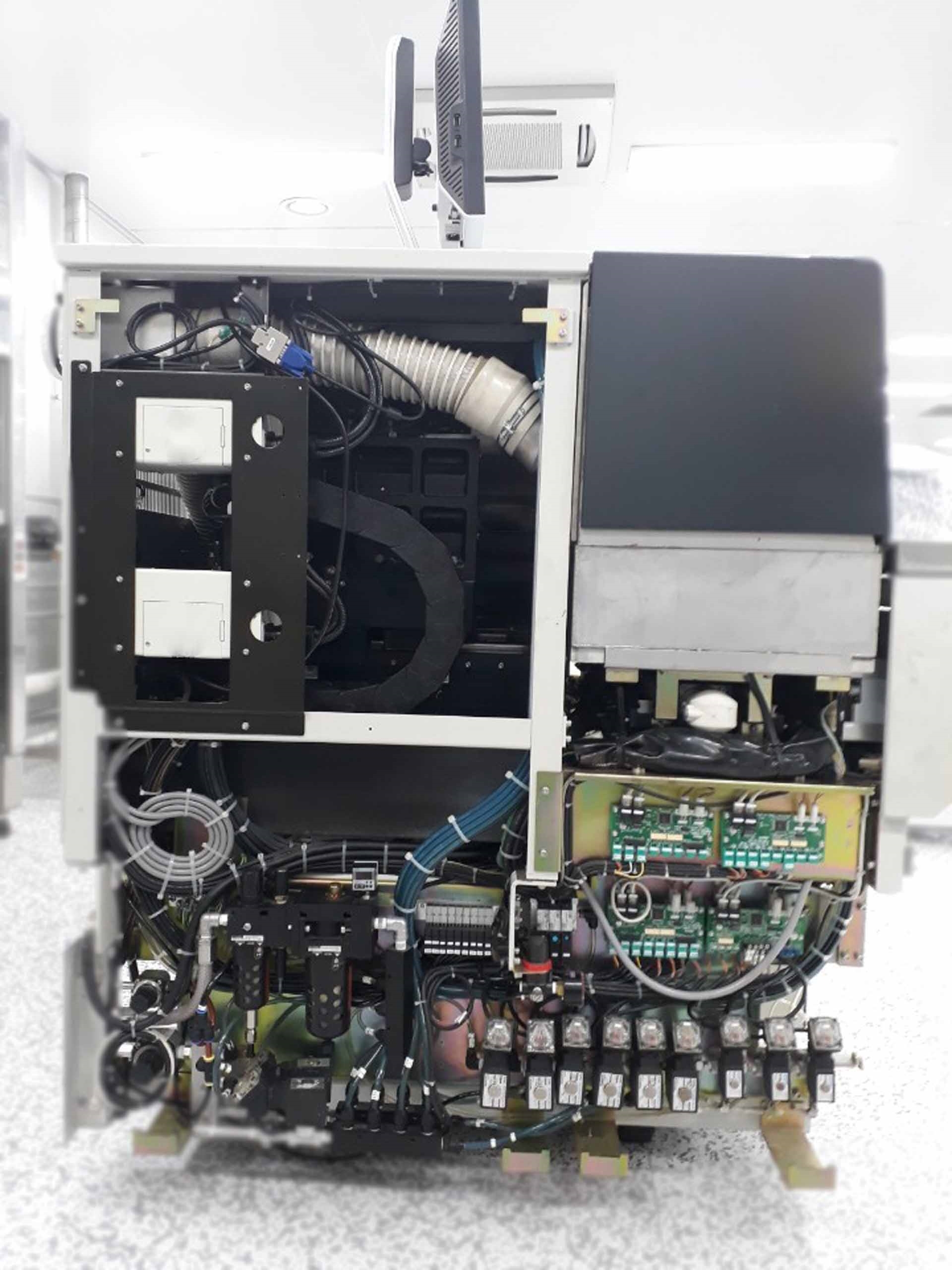

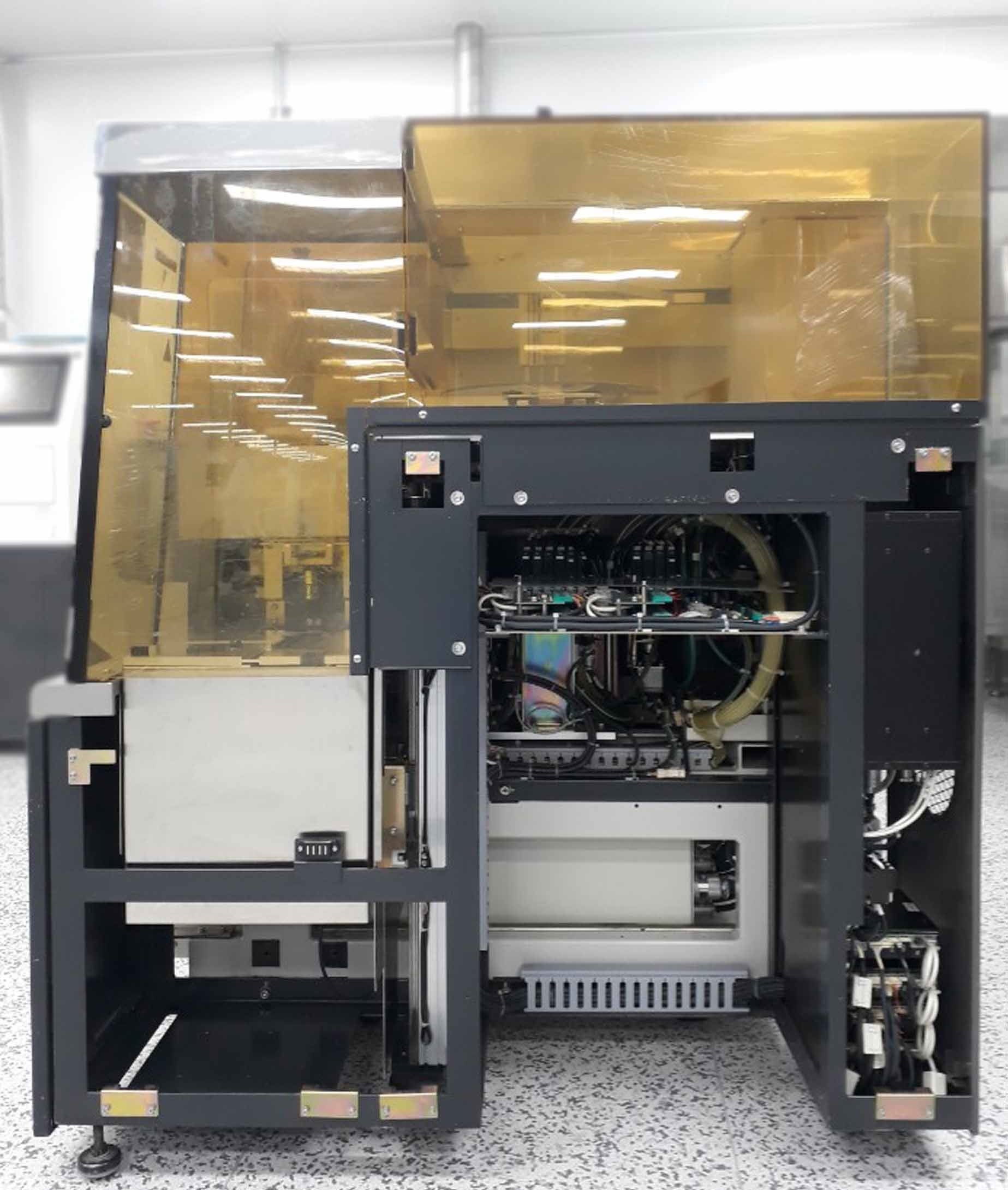

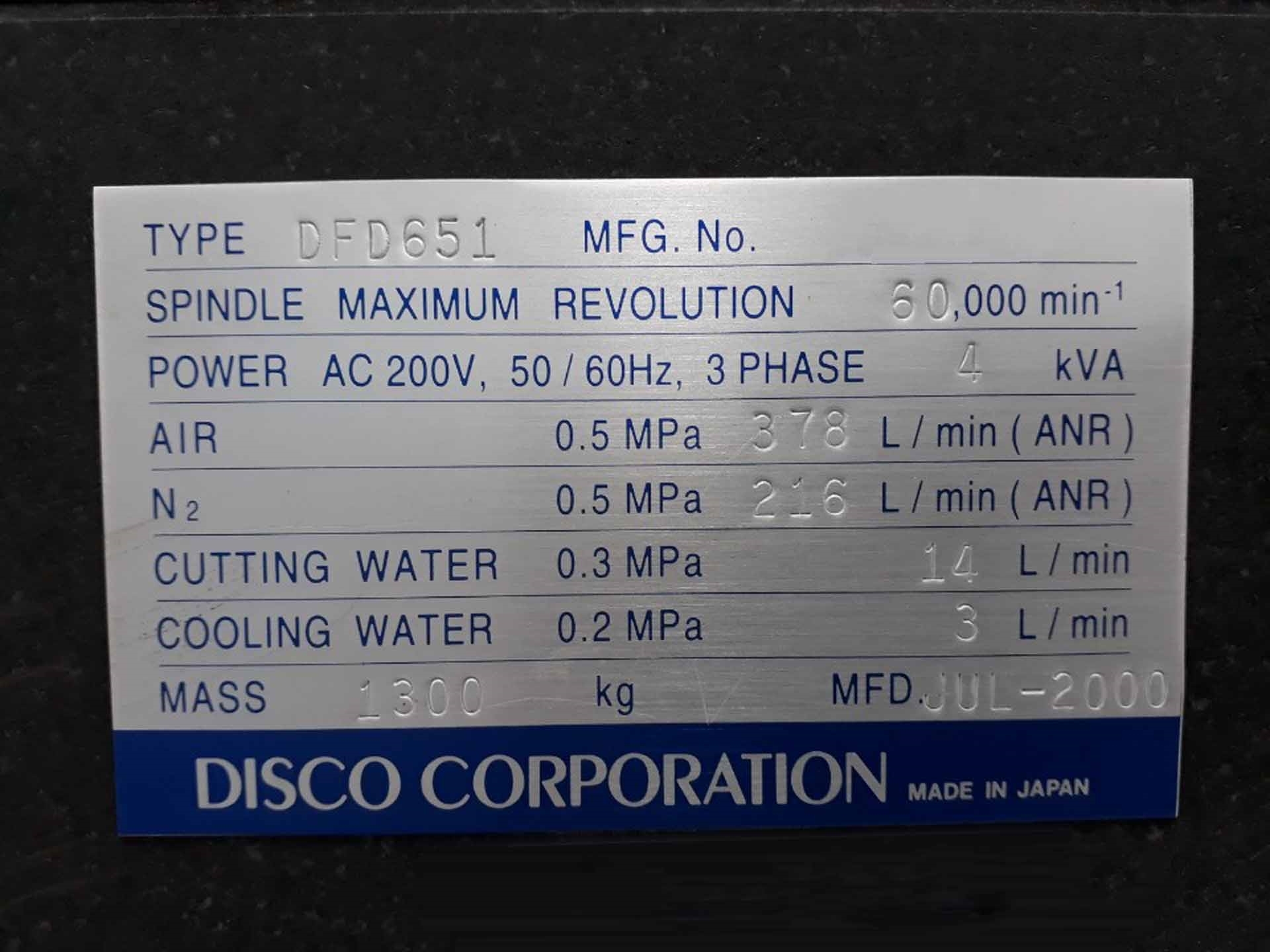

二手 DISCO DFD 651 #9220904 待售

网址复制成功!

单击可缩放

ID: 9220904

优质的: 2000

Dicing saw

Cutting section:

X-Axis:

Cut speed: 0.004 to 17.7"/sec

Cutting range: 8.27"

Work width setting range: 0" to 8"

Y-Axis:

Index step: 0.0001 mm

Cutting range: 8.28"

Positioning accuracy: 0" to 8"

Maximum stroke: 1.02"

Z-Axis:

Maximum stroke length: 1.0"

Travel resolution: 0.00025 mm

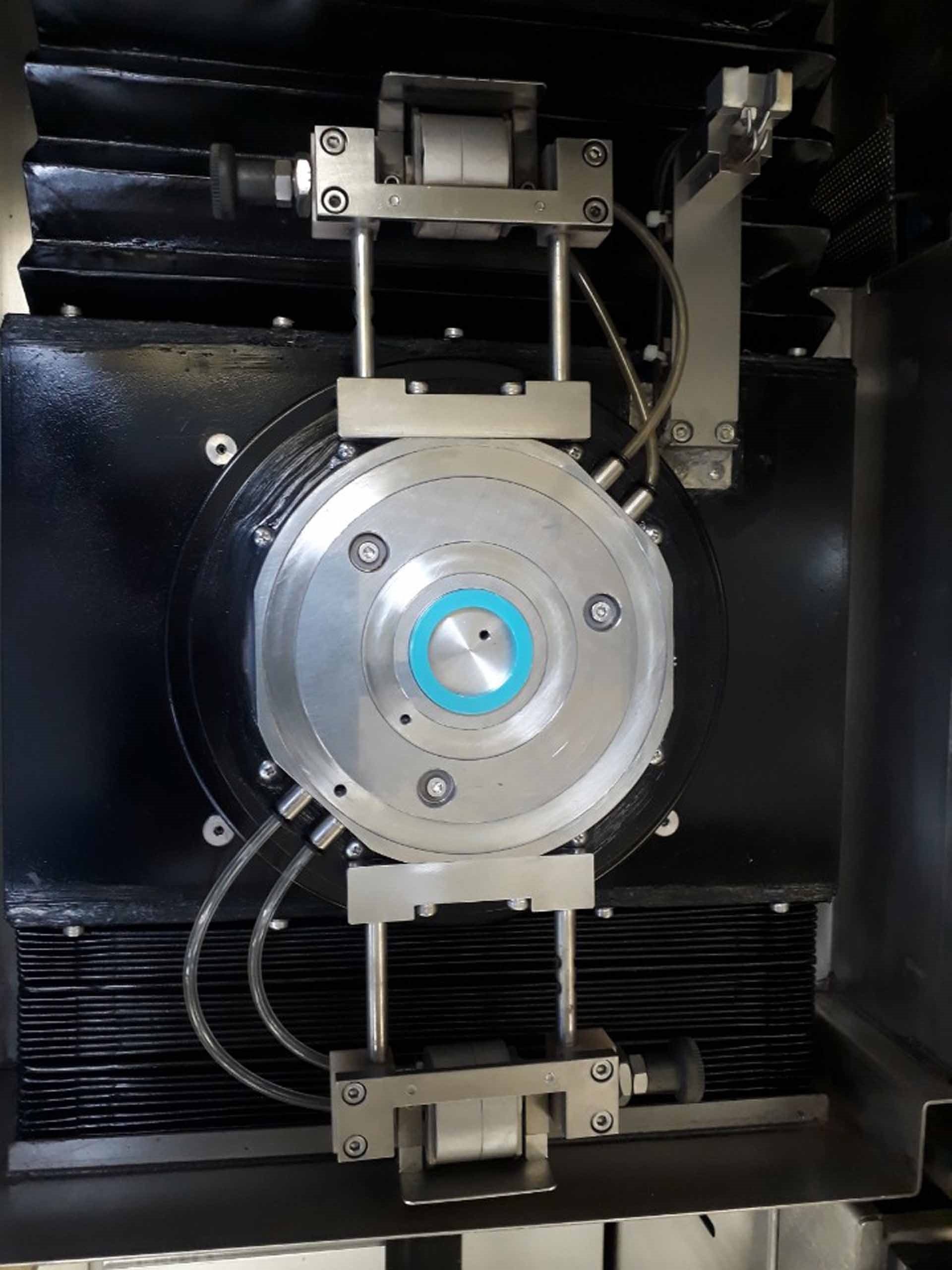

θ-Axis:

Maximum rotation angle:

380°

320° CW

60° CCW

Motor resolution: 0.66 s

Section:

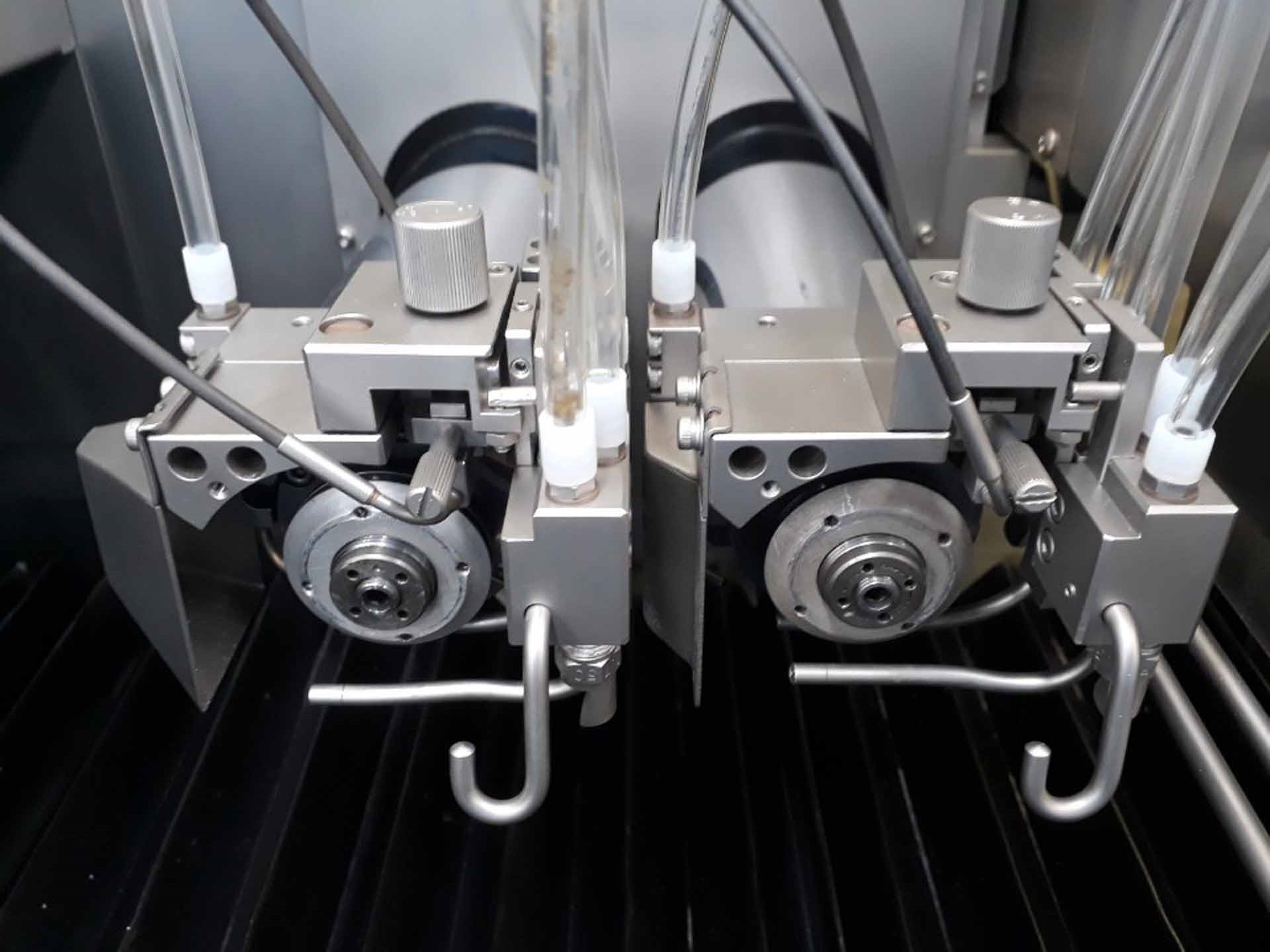

Mechanism:

Bearing: Air bearing

Motor: DC Brushless motor

Rotating speed range: 6,000 to 60,000 RPM

Output: 1000 W

Microscope section:

Microscope:

(2) Objects & cameras

Single lens microscope

Magnification:

On low magnification: 37x (On monitor)

On high magnification: 375x (On monitor)

Utilities section:

Air requirements:

Supply pressure: 0.5 to 0.6 MPa.G (72.5 to 87PSI)

Filtration: .00001 mm / 99.5% or higher

Residual oil content: 0.1 PPM Wt / Wt

Atmospheric dew point: -15° C or Less (-5° F)

Connection port: Rc (PT) 3/8" female

Maximum consumption: 378 l/min (13.34 CFM)

N2 Requirements:

Supply pressure: 0.5 to 0.6 MPa.G (72.5 to 87PSI)

Connection port: Rc (PT) 3/8" female

Maximum consumption: 216 l/min (7.63 CFM)

Water requirements:

Wheel coolant pressure: 0.3 MPa (43.5 PSI)

Water temperature:

Room temp + 2° C (Room temp + 4° F)

Connection port: Rc (PT) 3/8" female

Flow rate setting range:

1.0 to 12.0 l/min (0.26 to 3.17 GPM)

Spindle coolant pressure: 0.2 MPa (29.0 PSI)

Water temperature: Room temperature

Connection port: Rc (PT) 3/8" female

Consumption flow rate: 3 l/min (0.79 GPM)

Cleaning water:

Pressure: 0.3 MPa (43.5 PSI)

Connection port: Rc (PT) 3/8" female

Flow rate setting range: 1.0 l/min (0.26 GPM)

Water drainage:

Connection port:

Duct hose: 50 mm ID (1.97" ID)

Duct:

Duct capacity: 5.0 m^3/min or higher

Connection port:

Duct hose 3.94" ID (100 mm ID )

Power requirements:

Input voltage: Three-phase, 200 VAC ±10%

Power frequency: 50-60 Hz

Maximum power consumption: 5.2 kVA

2000 vintage.

DISCO DFD 651是一款为高精密切割硬质和脆性材料而设计的涂抹和切割设备。它利用高精度的金刚石刀片将材料快速准确地修剪成所需的尺寸和形状。DISCO DFD651由一个金刚石涂层的切削刃与一个垂直操作平台连接在基座上,可以根据材料的预期形状进行升降。它还具有可微调的端点,在修剪不同长度或厚度的零件时提高了精度。切割区域用强大的LED灯照明,在定位和控制材料切割时提供可见性和准确性。DFD-651中使用的刀片具有极强的耐用性和耐磨性,可提供更高的性能和可重复性。刀片可调节,达到各种切割深度,适用于不同厚度的切割材料。刀片还可调节地安装在精密龙门架上,从而能够精确定位刀刃。该系统带有一个脚踏开关,允许用户无需用手操作设备。脚踏开关还可用于在不同的切削深度之间快速切换,从而获得始终最佳的锋利切削刀刃。除了金刚石刀片外,DFD 651机还包括一个划线夹具,有助于提高薄切和轮廓形状的精度。划线夹具附着在切割头上,可以调整到不同的高度和角度设置。这使得它适用于生产薄盘等复杂形状,以及用于医疗器械制造的剥离细线。DISCO DFD-651还配备了开放式架构计算机工具,允许用户创建切割程序以加快其生产工作流程。它设计为用户友好、高效,允许用户轻松调整设置,创建和保存新的切割程序,并监控切割过程。DFD651是快速准确切割薄脆材料的理想工具。其耐用耐磨的金刚石刀片、可调龙门和划线夹具,加上用户友好的计算机资产,使其成为一种用途广泛、可靠的型号,可用于各种行业和应用。

还没有评论