二手 DISCO DFL 7161 #9220486 待售

看起来这件物品已经卖了。检查下面的类似产品或与我们联系,我们经验丰富的团队将为您找到它。

单击可缩放

已售出

ID: 9220486

优质的: 2011

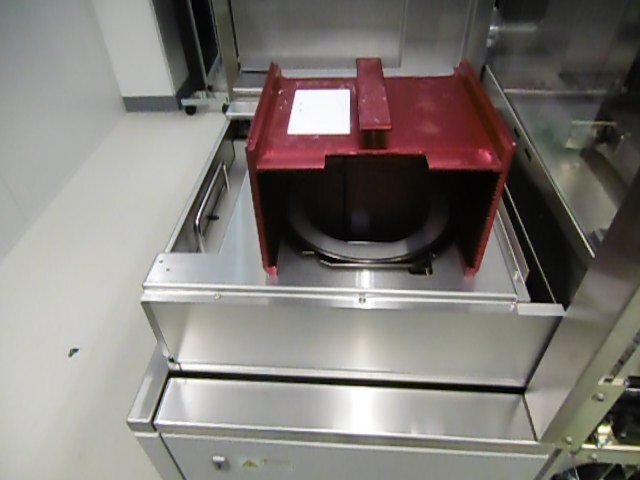

Fully automatic laser saw

(3) Chucks table, 6"

Field of application: Germanium wafer

Process chamber (Glass)

Coating and spinner (Porous)

Configured for cutting semiconductor substrates

Running hours: 383

Standby hours: 30,640

Laser head hours: 3743

Laser:

COHERENT AVIA 355-28 Power curve

Type-K with BSS4 Optical system

Head hours: 3,743

Nozzle: K-02

Pulse: ~30 ns

28 W of 355 nm at 110 kHz

E-Beam

Perm align solder-bonded optics technology

Aluminum-Free Active Area (AAA) (Diode material)

Field replaceable pump diode modules

Smart power supply with RS-232 interface

Pulse control system

HGX UV Generation technology

ThermEQ For uniform pulse energy across a burst of pulses

PulseEQ For locked pulse energy across a range of pulse repetition rates

PulseTrack For on-the-fly pulse energy control

Wavelength: 354.7 nm

Average output power:

26 W at 90 kHz

28 W at 110 kHz

23 W at 150 kHz

18 W at 180 kHz

Nominal repetition rate: 110 kHz

Beam optimization: 110 kHz

Motorized crystal shifter: 75 Spots/300 hours

Pulse repetition rate single-shot: 300 kHz

Pulse-to-pulse stability (Up to 140 kHz): <5% (1σ rms)

Average power stability (Over 8 hours): <2% (2σ rms)

Polarization ratio²: >100:1 Horizontal

Spatial mode²: TEM00 (M2 <1.3)

Beam divergence full angle²: (mrad): <0.3

Pulse width: <40 ns Up to 110 kHz

Beam pointing drift³: <25°C/μrad

Near-field pointing and rep. rate with posilock: 50 μm

1/e² Beam diameter²: 3.5 ±0.35 mm

Beam circularity: >85%

Warm-up time:

Standby mode: <15 Minutes

Cold: <40 Minutes

Bore-sight accuracy: ±0.5 mm and ±5 mrad

RoHS Compliant

Utility:

Single phase operating voltage: 100 to 240 VAC (Auto ranging)

Line frequency: 50/60 Hz (Auto ranging)

Laser power consumption: 900 W, 1.7 kW Maximum

Missing housing components:

LPAC-022222-1 Cover (R, F)

(2) LPAC-022223-3 Covers (R, B-R)

LPAC-022151-2 Cover (F, L)

2011 vintage.

DISCO DFL 7161是一款为精密晶圆半导体加工而设计的涂抹和切丁设备。它具有双扫描双激光技术和每个激光束独立的横轴。这使它能够在高精度公差范围内创建精确的网格模式,并且适用于各种过程。DISCO DFL7161具有较高的光路设计,允许使用各种晶圆尺寸,并且可以连接到用于化学机械抛光(CMP)的设备以及其他晶圆工艺。它具有集成的设计,无需夹具,有助于提高生产效率,同时其高速处理能力确保它能够跟上最新的半导体生产过程。DFL 7161有一个特殊的功能,不需要工程师监控对齐过程,允许操作员最小化设置和校准时间。它还可以配备增强的激光控制单元,以减少激光像差,轻松控制多个激光器。这种划线和切割系统还支持自动补偿功能,自动检测晶圆表面差异并相应补偿。激光功率调节装置能够根据不同晶片类型调节激光功率,对每个晶片的切削精度进行微调,确保产生最一致的切削。DFL7161是一种经久耐用的机器,可承受长期运行并符合ISO 14001环境规范。它具有出色的可用性和支持,使其易于与其他工具集成。此外,还优化了排放间隔管理,以减少浪费和控制成本。DISCO DFL 7161是精密半导体加工必不可少的涂抹和切碎机。它的双激光技术、精度公差和自动补偿能力使其非常适合创建高生产效率的精确网格模式。此外,它的可靠性和易操作性使得它成为任何一条半导体生产线的巨大投资。

还没有评论